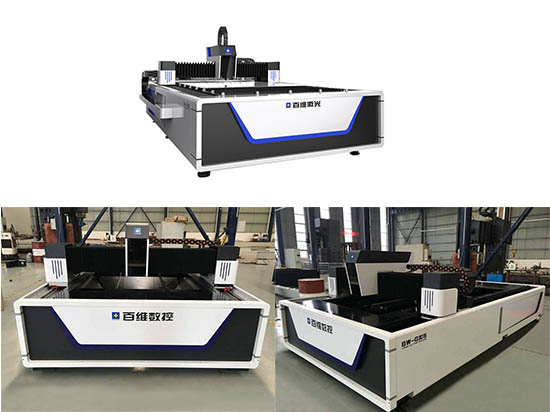

Fiber laser metal cutting machine for metal stainless steel iron

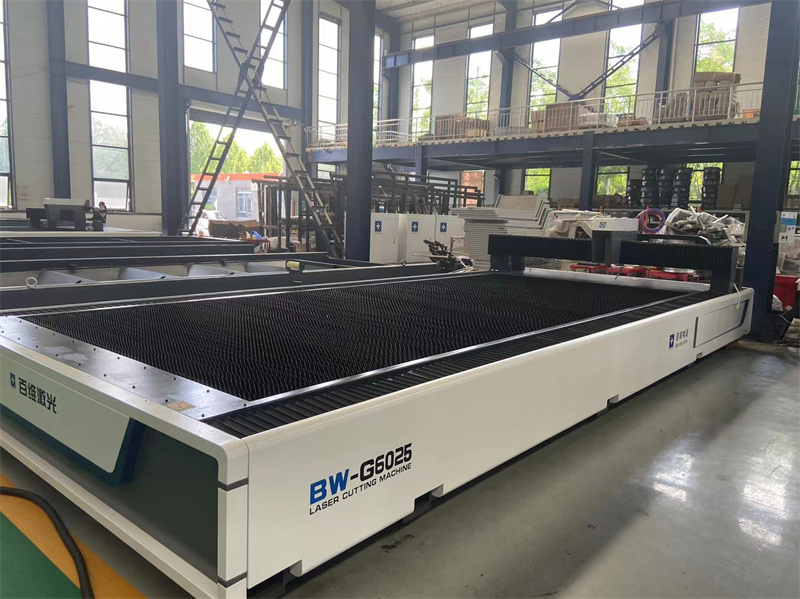

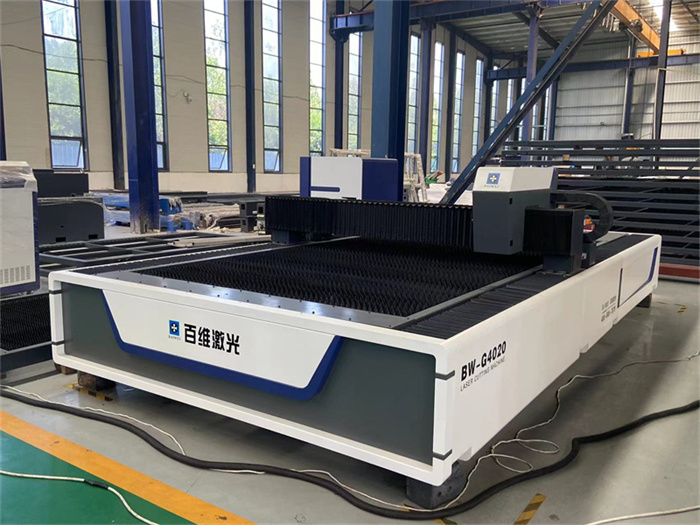

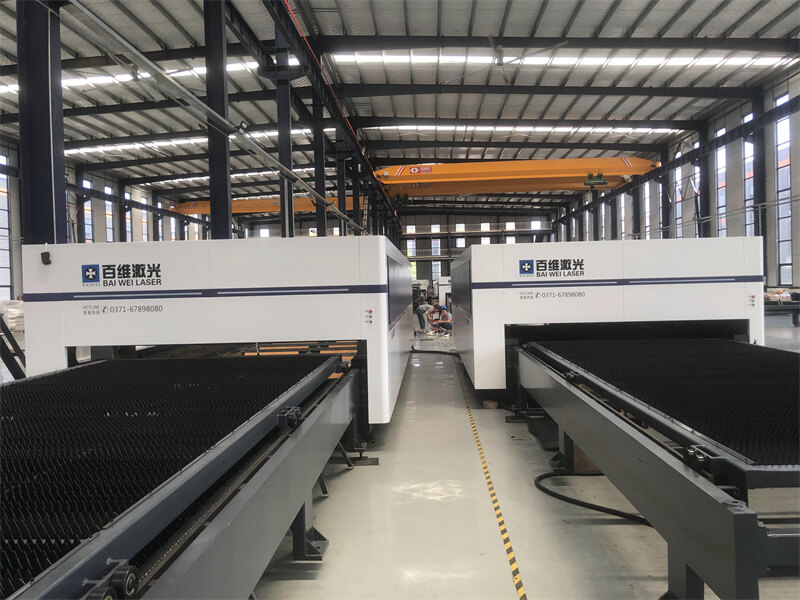

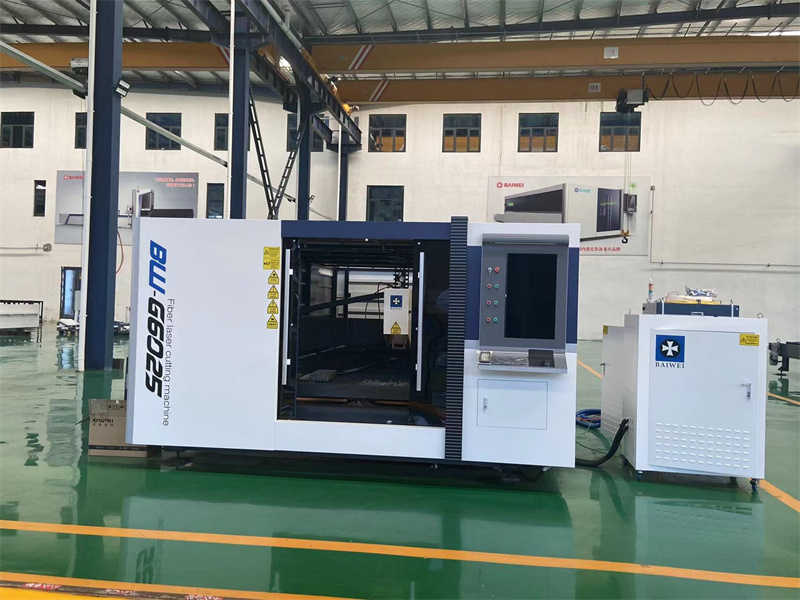

Model: BW-G12025

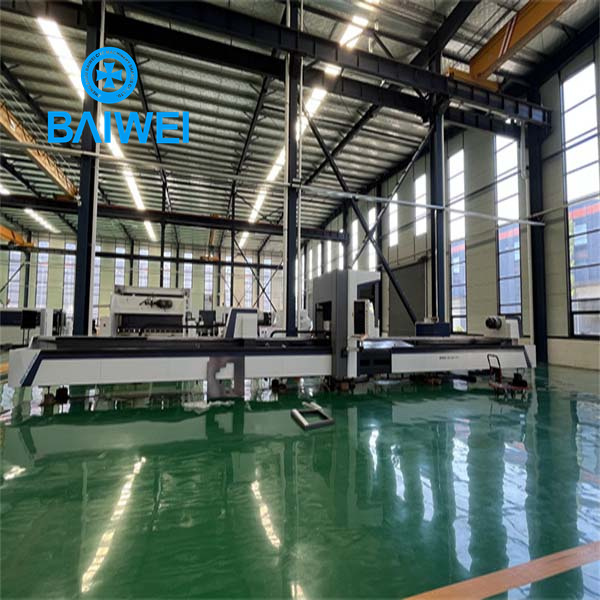

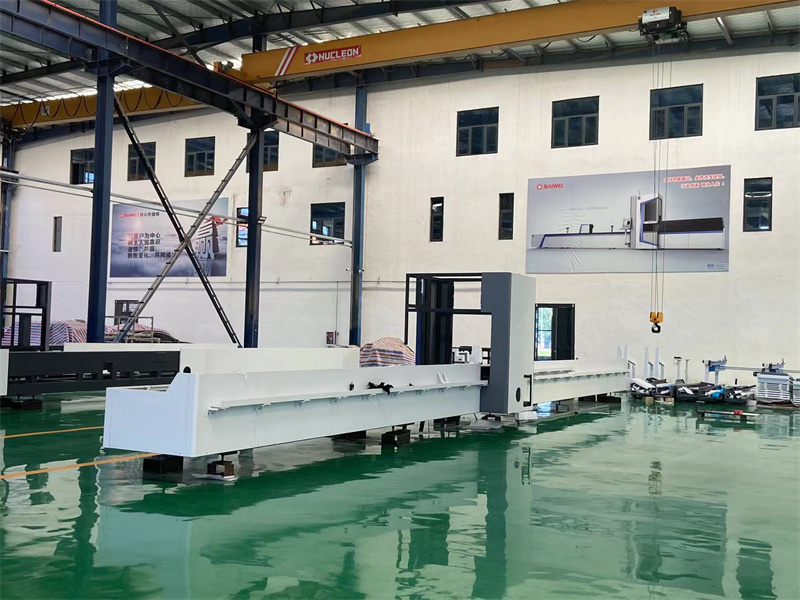

Cutting range: 12000x2500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 100m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

The laser beam is a column with a very high intensity of light, a single wavelength, or a color. In the case of a standard CO2 laser, the wavelength of the infrared portion of the light spectrum is invisible to the human eye. The beam is just around 3/4 inch in diameter as it passes through the beam path of the system from the laser resonator that produces the beam.

It can be bounced in various directions by a range of mirrors, or “beam benders,” until it is eventually placed on the plate. The focused laser beam passes through the bore of the nozzle just before it reaches the plate. The compressed gas, such as oxygen or nitrogen, is also flowing through the nozzle bore.

Focusing the laser beam may be achieved with a special lens or a curved mirror, and this is done in the laser cutting head. The beam must be precisely oriented in such a way that the shape of the focal spot and the density of the energy in that spot is perfectly round and consistent and centered in the nozzle. By focusing the broad beam down to a single pinpoint, the heat intensity at that point is intense.