Fiber Laser Cutting Machine – Get Nice Factory Price

Laser cutting is already a very common application in laser processing technology. With the development of industrial manufacturing, the core components of laser cutting machines have been normalized, so that the cost of lasers has dropped, and laser cutting technology has become more mature. It is believed that with the development of the times, more and more enterprises will use laser processing equipment. As a light beam, laser itself has very good monochromatic performance. Through relatively high brightness and high energy density, the cutting direction can be shaped. It is widely used in cutting, drilling, welding in industrial processing. , cleaning and other aspects, there is a large space for development in the market, with the potential for the development of different materials.

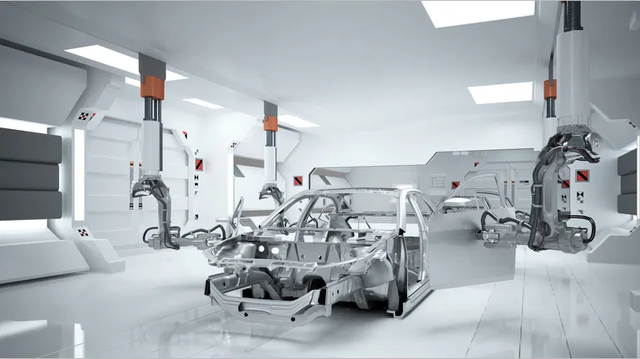

Laser cutting machines are currently widely used to cut common metal materials such as ordinary steel plates, some alloy materials, and stainless steel. In the industrial development, more and more sheet metal processing fields need to be processed, and more industrial cities need to be established. Tell you about the technology center, thus improving economic efficiency. In the application of laser cutting machine in the sheet metal processing industry, the laser cutting speed is fast, the slit is small, the incision part is smooth and neat, the thermal effect is small, the raw material will not be deformed, and the overall cutting quality is better, which is comparable to the traditional cutting technology. Compared with the laser cutting machine, there will be no wear on the cutting tool, the cutting range is relatively large, and it will not be affected by the shape of the material. It can realize automatic cutting. For complex processing methods, it is not necessary to borrow molds. It still maintains high-quality, high-precision cutting work.