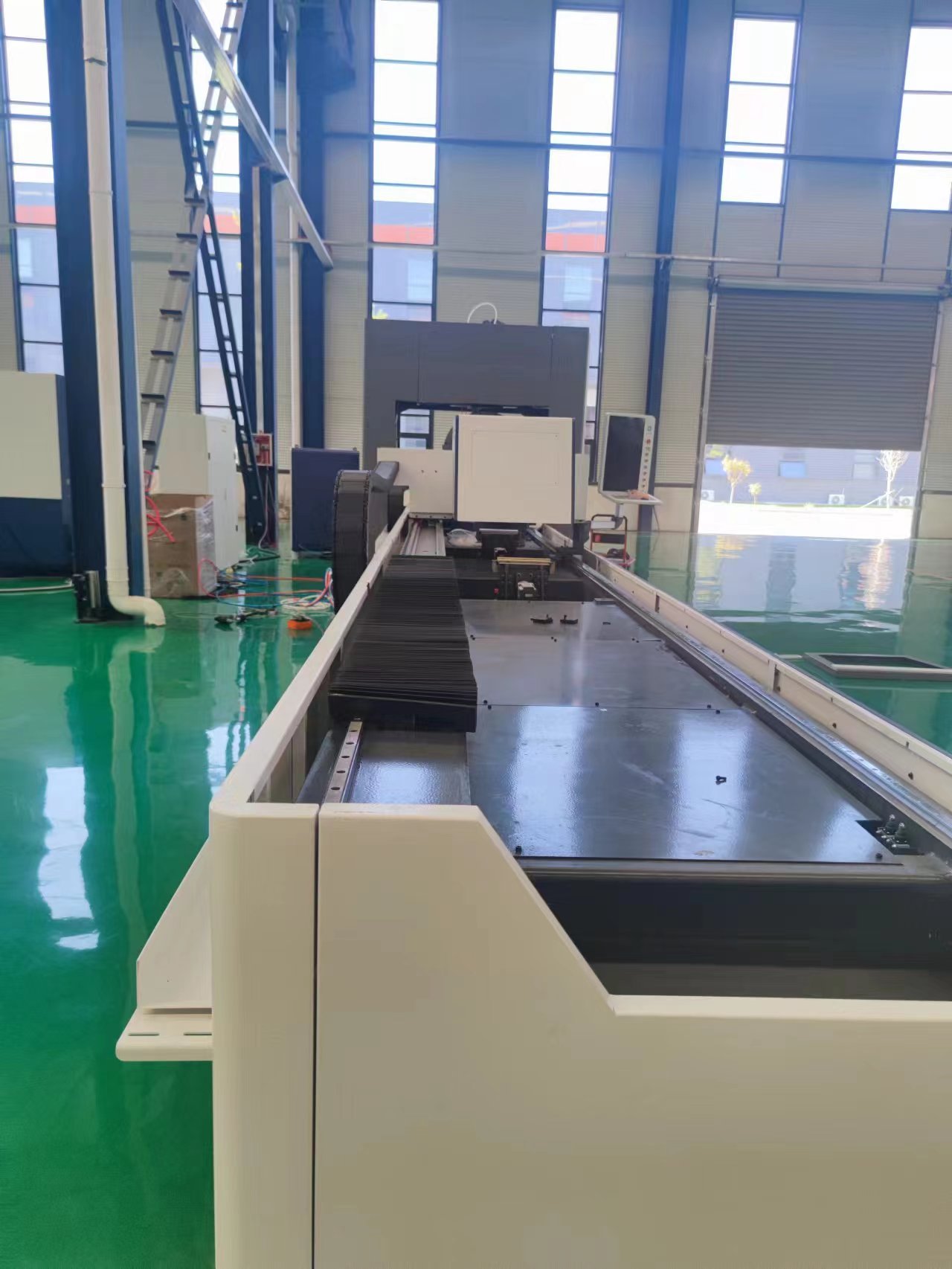

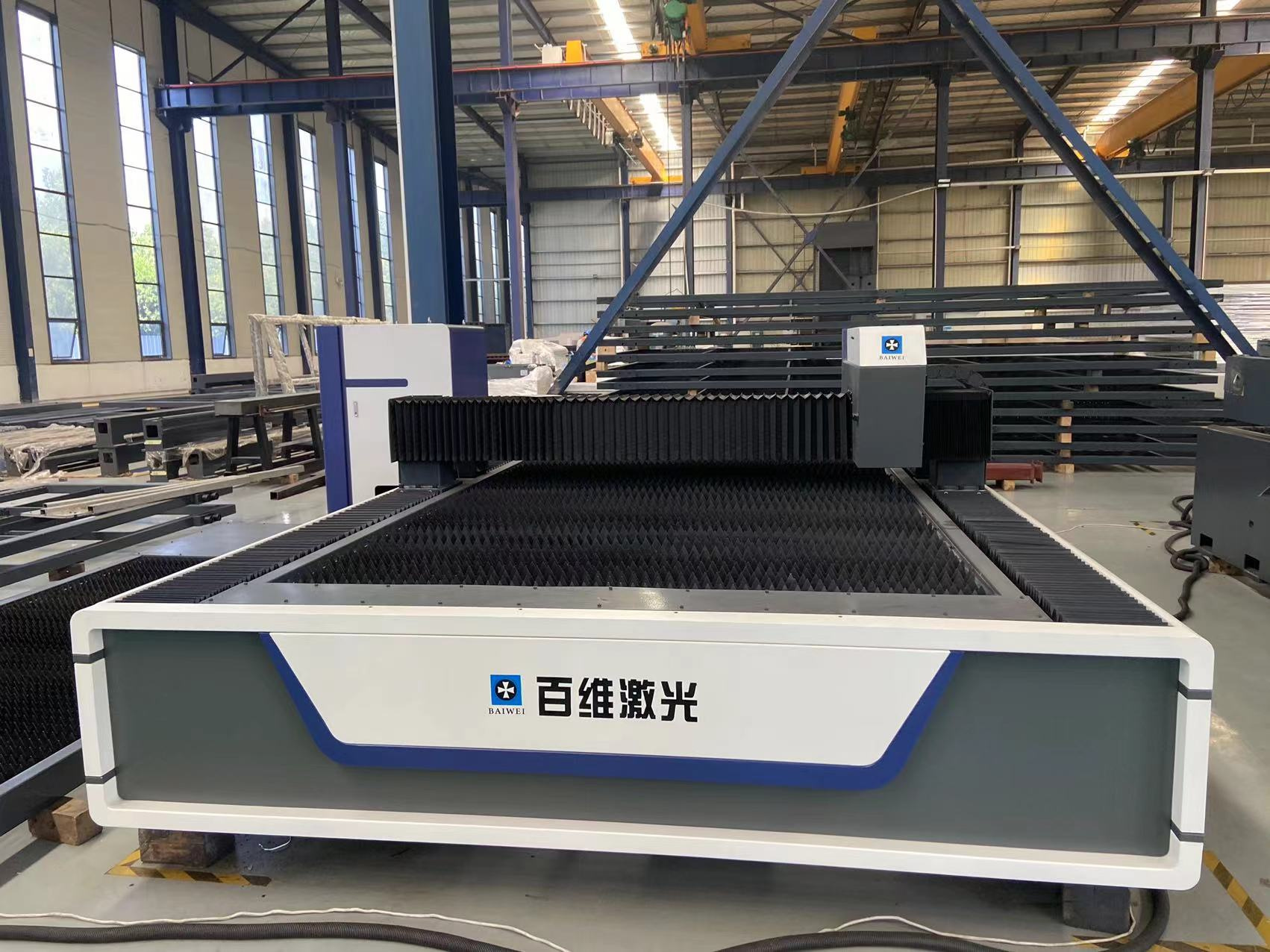

Fiber laser cutting machine-CNC Milling Machine for Aluminum Molds Making Projects

Parameter

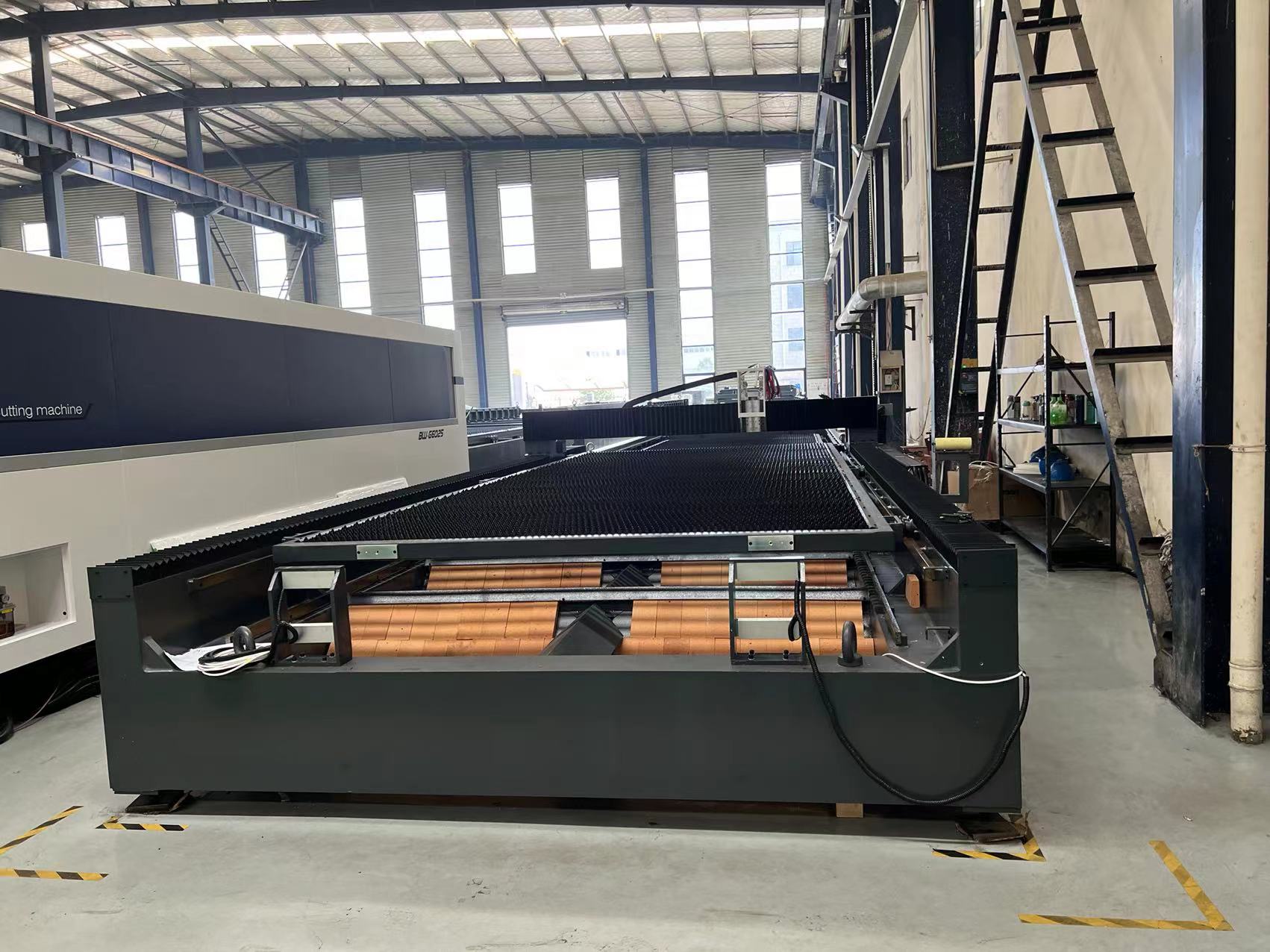

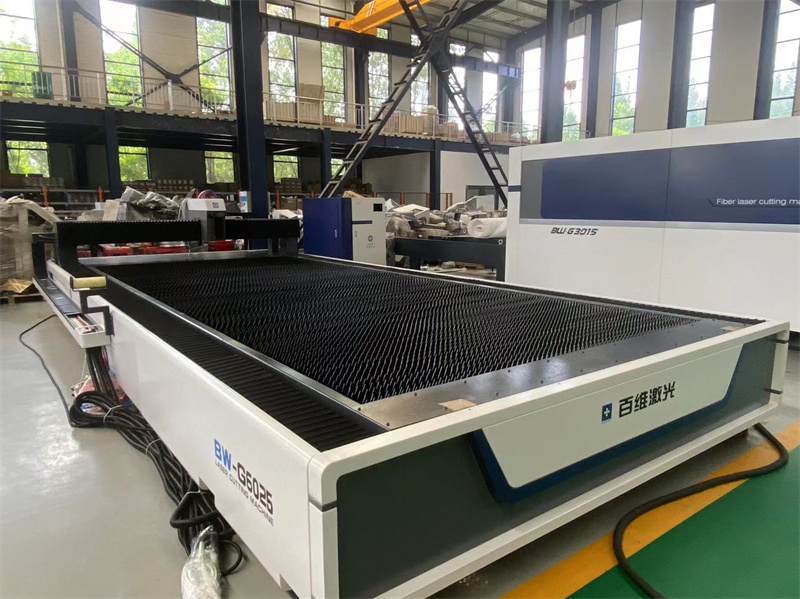

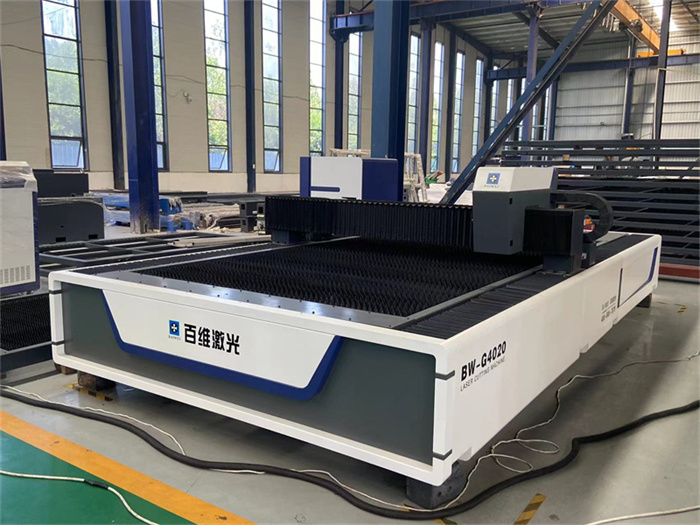

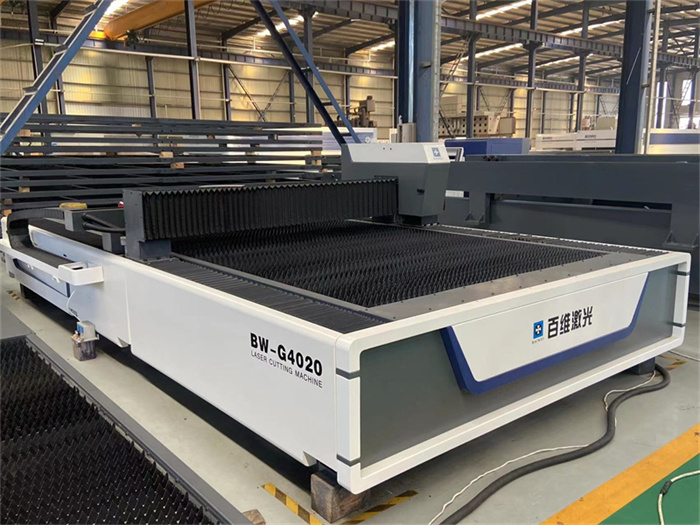

Models BW-G3015 BW-G4015 BW-G4020 BW-G6015 BW-G6020 Optional

Cutting range 3000x1500mm 4000x1500mm 4000x2000mm 6000x1500mm 6000x2000mm Optional

Laser power 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw

Max moving speed 100m/min

Max cutting speed 35-80m/min

Positioning accuracy 0.03mm

Repositioning accuracy 0.02mm

Min line width 0.1mm

At present, the application directions of laser cutting equipment on the market mainly include the following three categories:

The first category is processing materials for decoration, advertising, lamps, kitchen utensils, thin sheet metal parts, electrical cabinets, elevator panels, engineering boards, and high and low switch cabinets. These materials are generally thin, stainless steel plates with a thickness of 1-5mm. The material can be cut with a medium power laser cutting machine.

Aluminum and Alloys

Aluminum cutting is a melting cutting mechanism, and the auxiliary gas used is mainly used to blow away the molten product from the cutting area, and usually a better cutting surface quality can be obtained. For some aluminum alloys, attention should be paid to preventing the generation of intergranular micro-cracks on the surface of the slit.