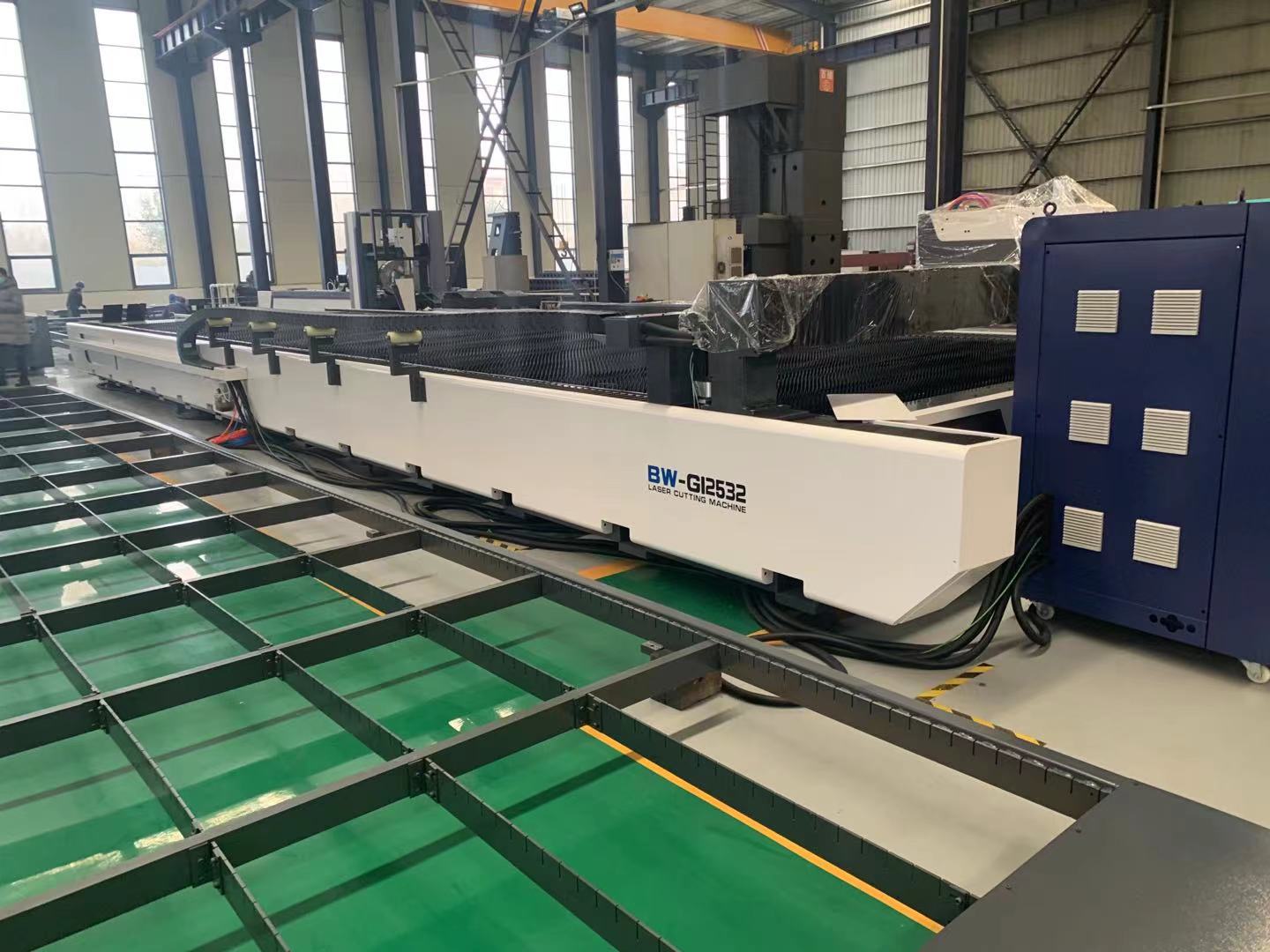

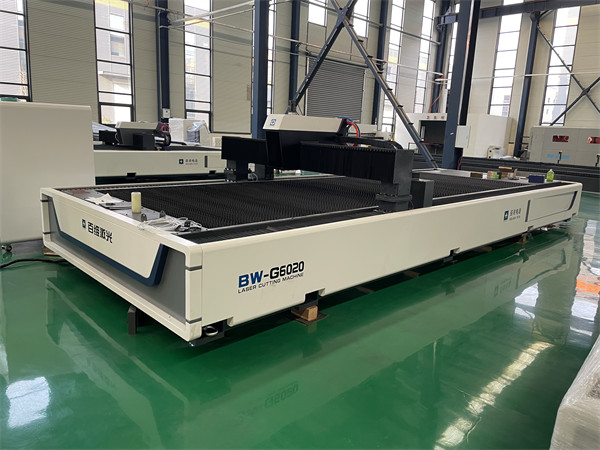

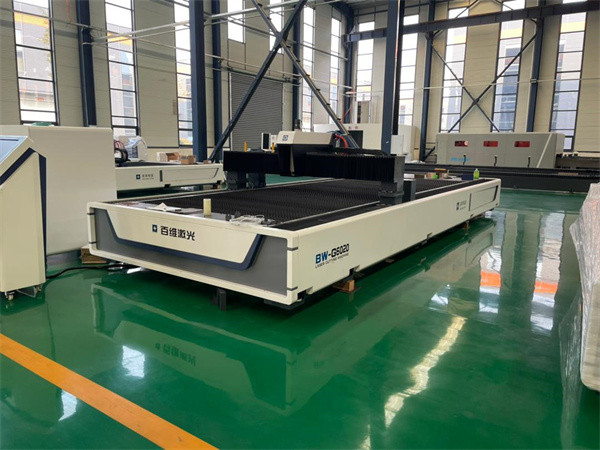

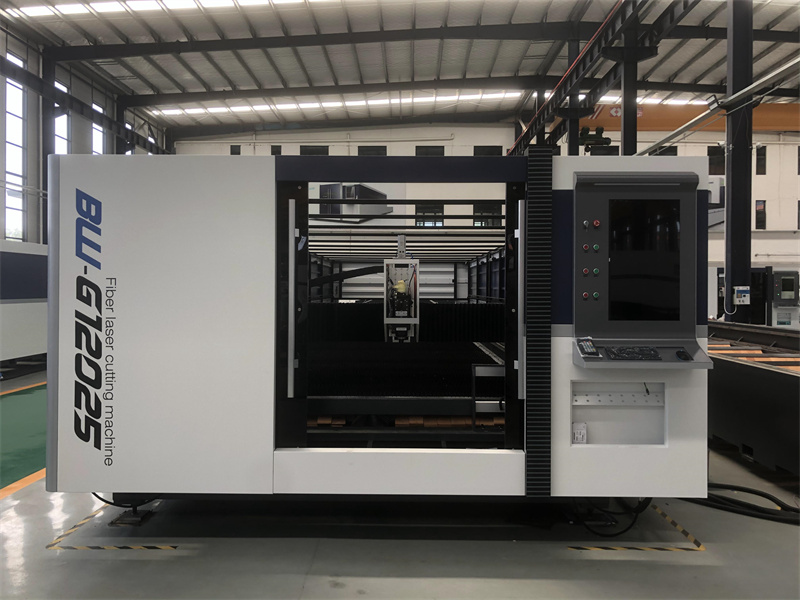

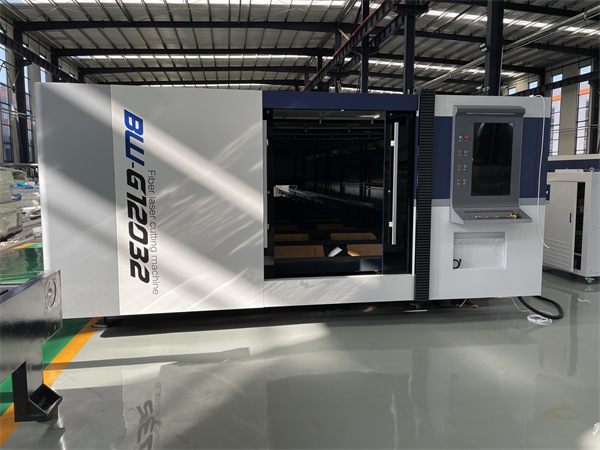

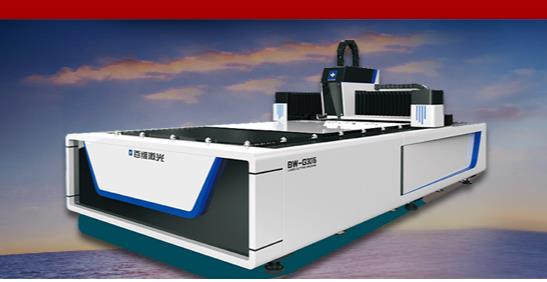

Fiber Laser Cutting Machine 1000W 2000W 3000w 4000w 1500*3000mm Cutting Area for Brass Copper Iron Carbon Cutting Made in China

Parameter

Models BW-G3015 BW-G4015 BW-G4020 BW-G6015 BW-G6020 Optional

Cutting range 3000x1500mm 4000x1500mm 4000x2000mm 6000x1500mm 6000x2000mm Optional

Laser power 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw

Max moving speed 100m/min

Max cutting speed 35-80m/min

Positioning accuracy 0.03mm

Repositioning accuracy 0.02mm

Min line width 0.1mm

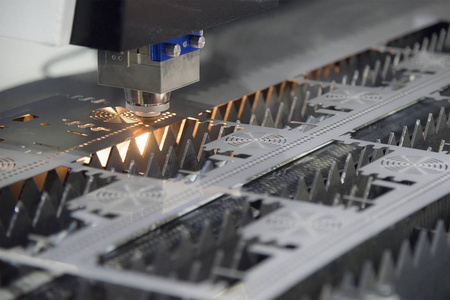

Carbon steel:

The maximum thickness of carbon steel plates that can be cut by modern laser cutting systems is very close, and the slits of thin plates can be as narrow as about 0, 1mm. The heat affected zone of laser cutting mild steel is extremely small, and the incision is flat, smooth and vertical. For high carbon steel, the edge quality of laser cutting is better than that of low carbon steel, but its heat affected zone is larger. The maximum cutting depth of our company’s AHL series laser machine is 5mm.

Aluminum and Alloys:

Aluminum cutting is melting cutting, which uses auxiliary gas to blow away the molten material in the cutting area, so as to obtain better cutting surface quality. At present, the maximum thickness of cutting aluminum plate is 1.5mm.