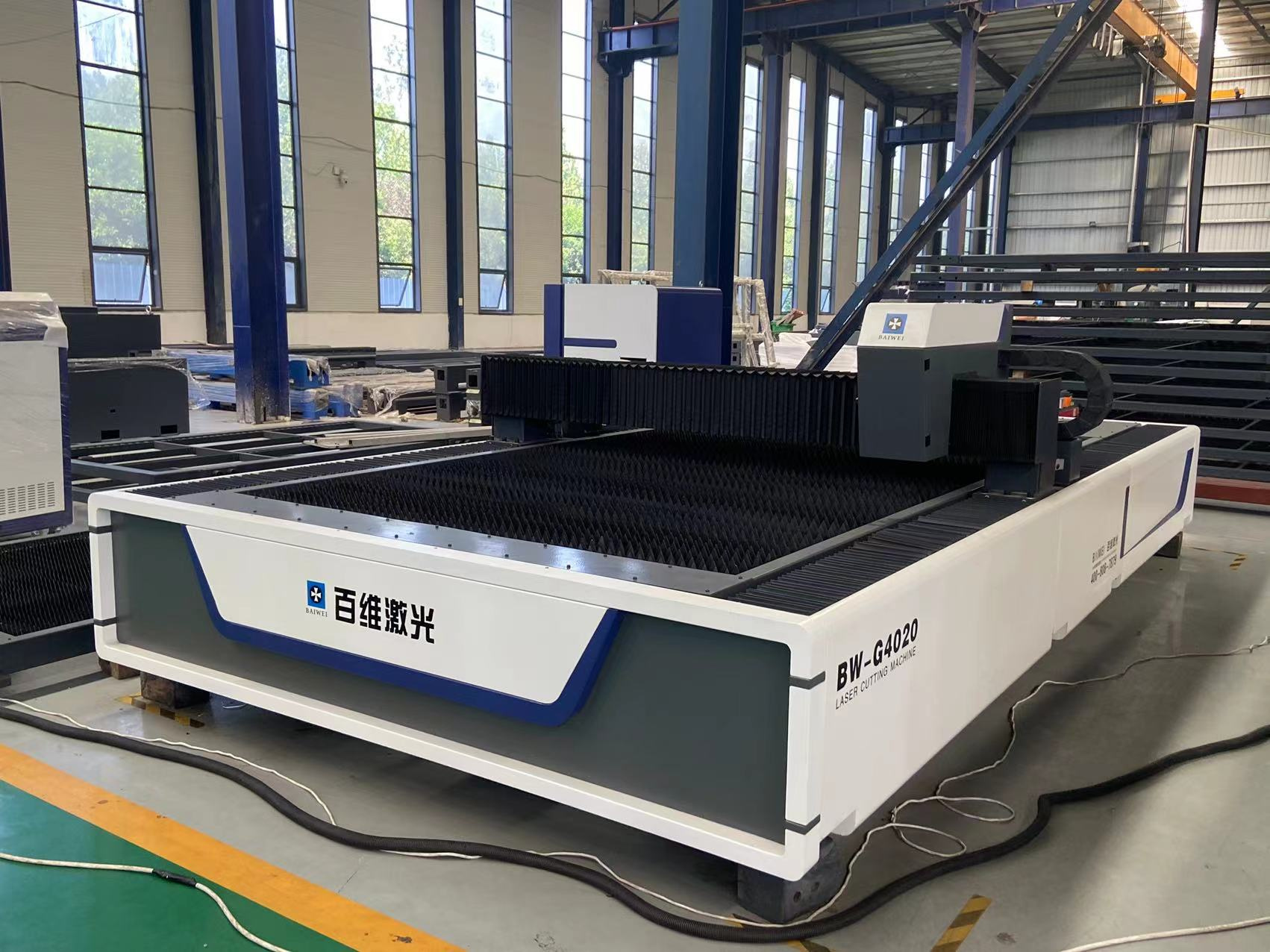

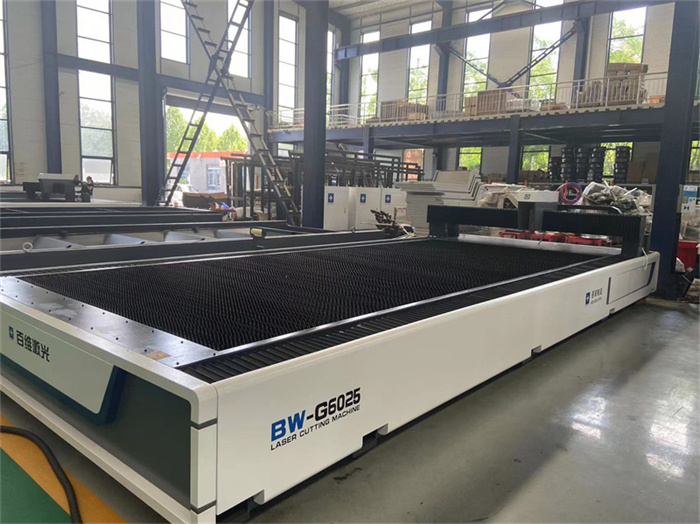

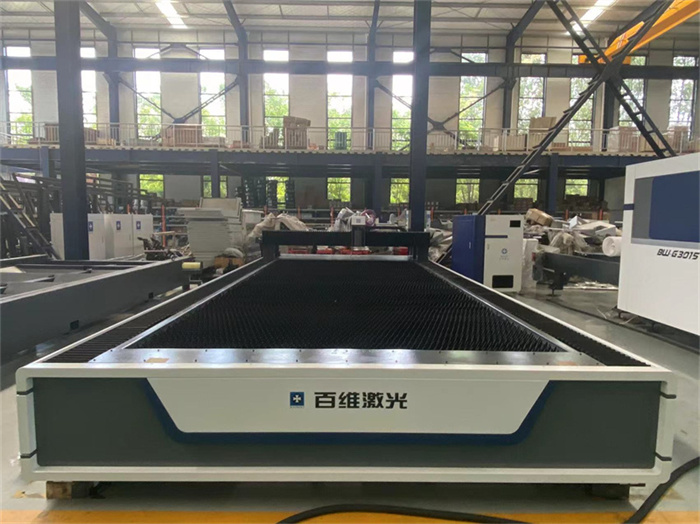

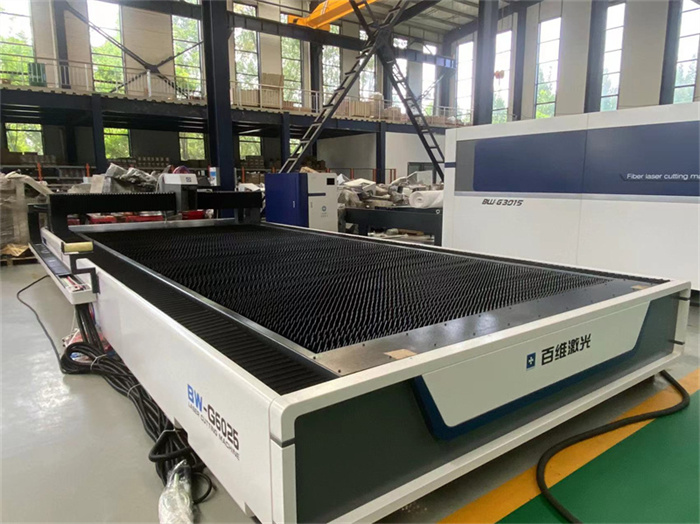

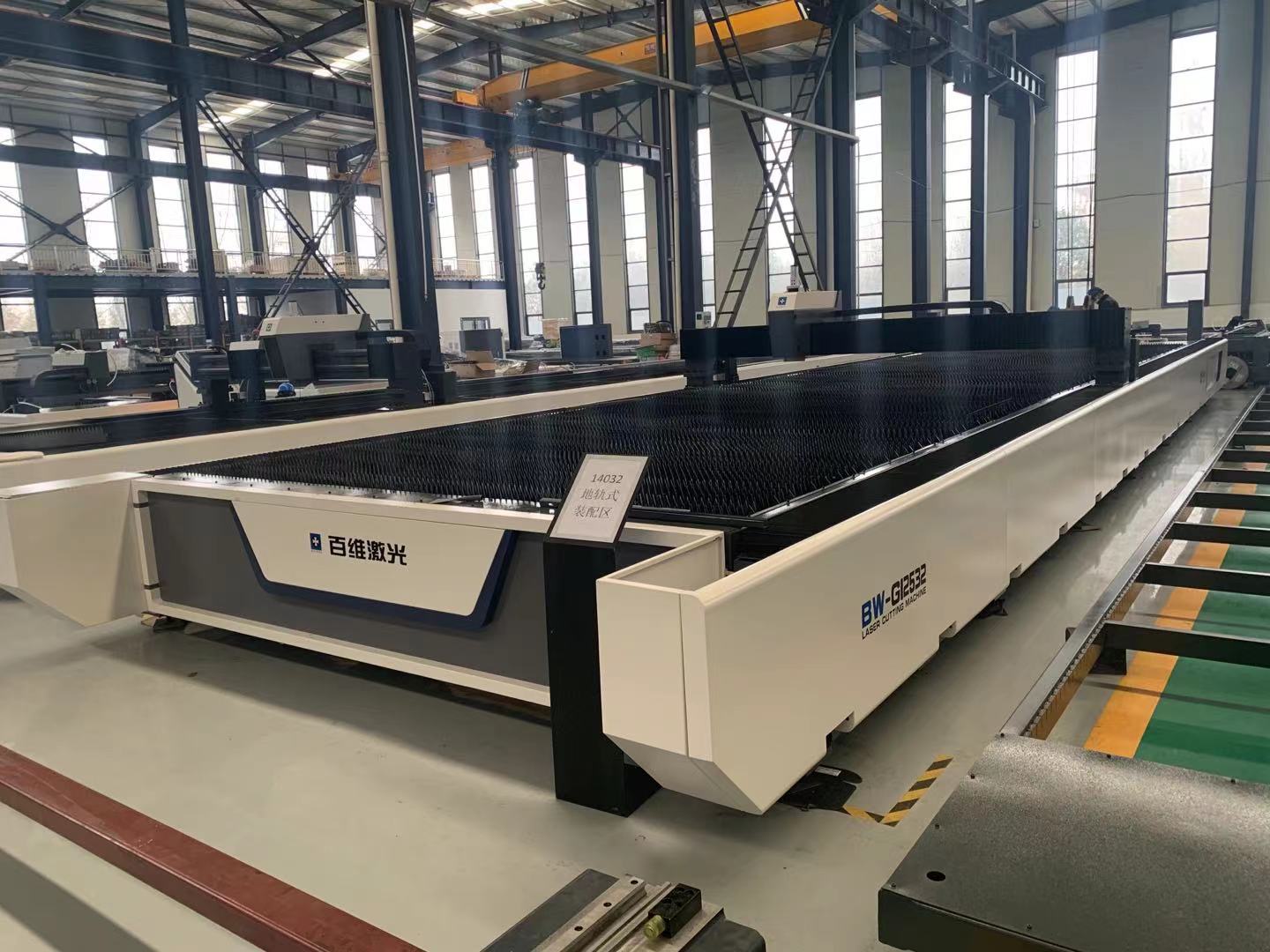

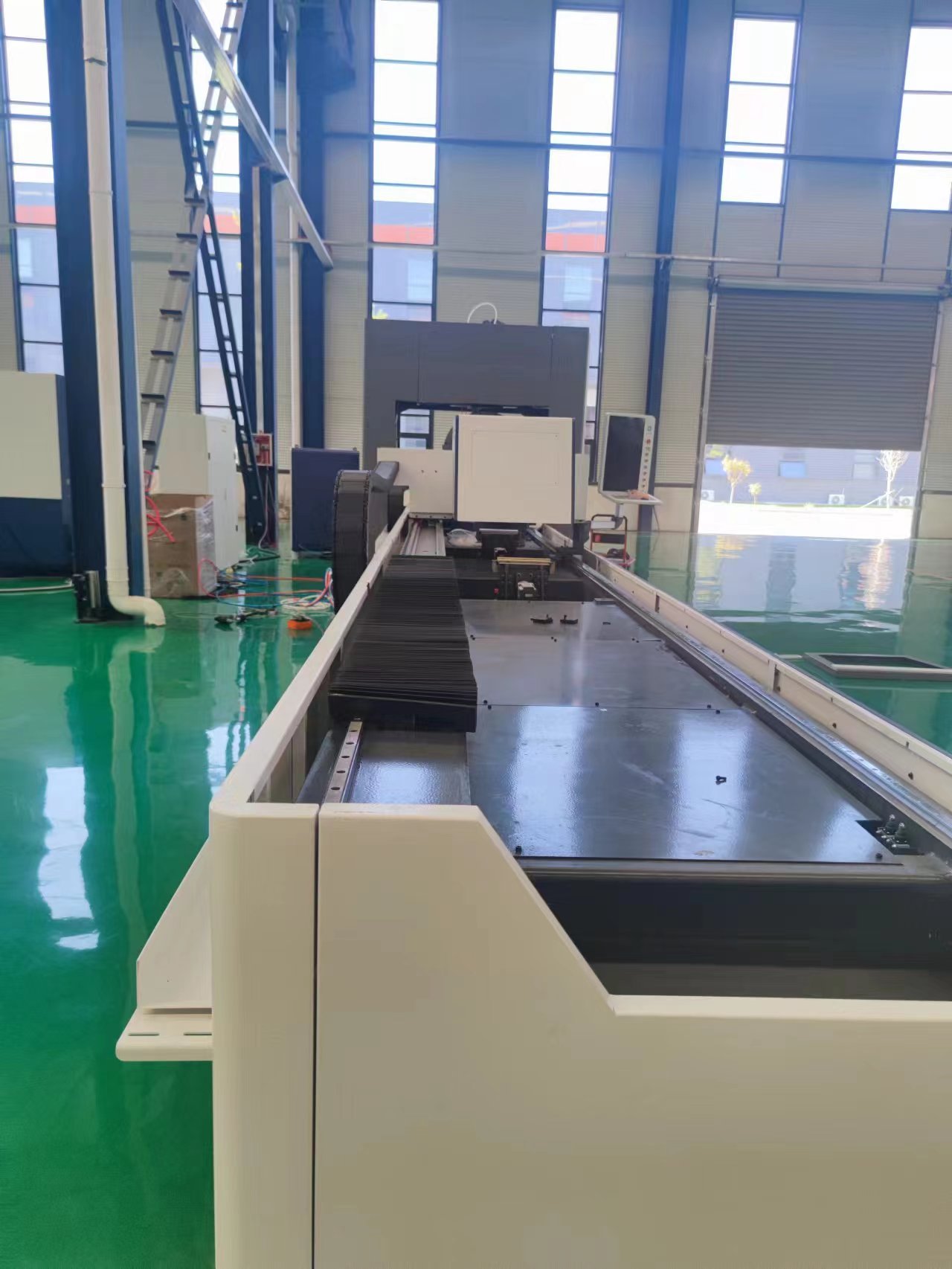

fiber laser cutting for shipbuilding

Low processing cost. The one-time investment in equipment is expensive, but continuous large-scale machining ultimately reduces the machining cost per part.Output Power:

2kw/3kw/4kw/6kw/8kw/12kw (Optional)

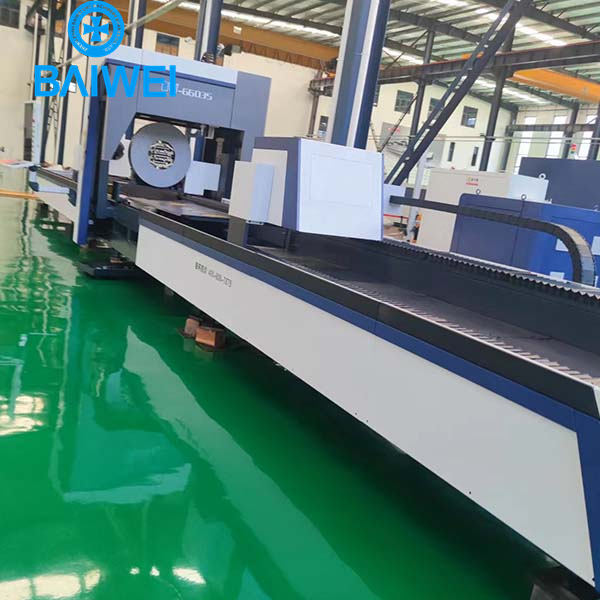

Model:

BW-G6000/BW-G9000/BW-G12000 (Optional)

Tube Diameter:

160mm/240mm/280mm/350mm/450mm/500mm (Optional)

Compared with traditional processing technology, laser cutting machine has obvious advantages. Laser cutting combines a high concentration of energy and pressure, making it possible to cut smaller and narrower areas of material with significantly less heat and material waste. Laser cutting has high precision and can process complex geometric shapes with smooth edges and more obvious cutting effects.Also, help minimize waste given that laser cutters can bring the cut parts very close to each other without negatively impacting them – tight cuts can yield more sheet metal per square meter used parts.