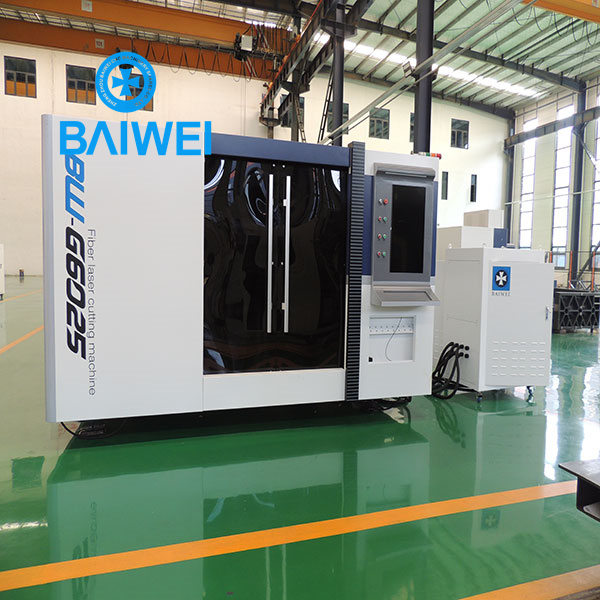

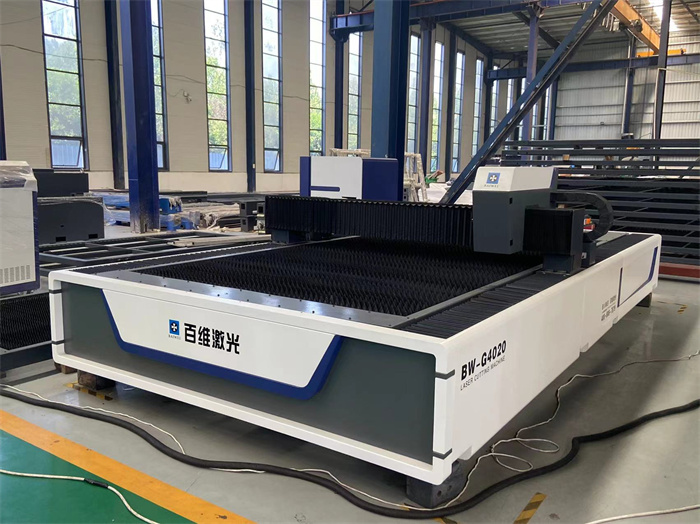

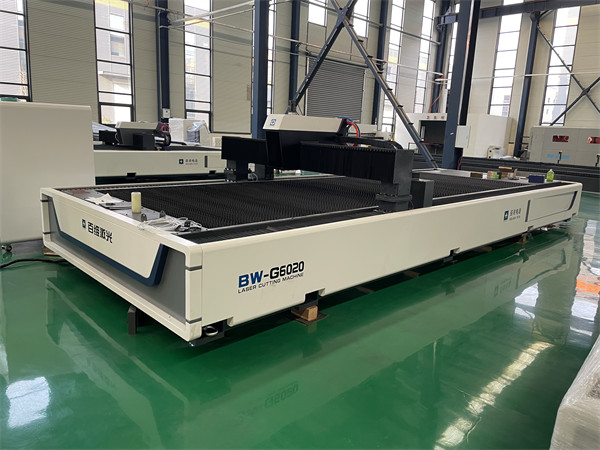

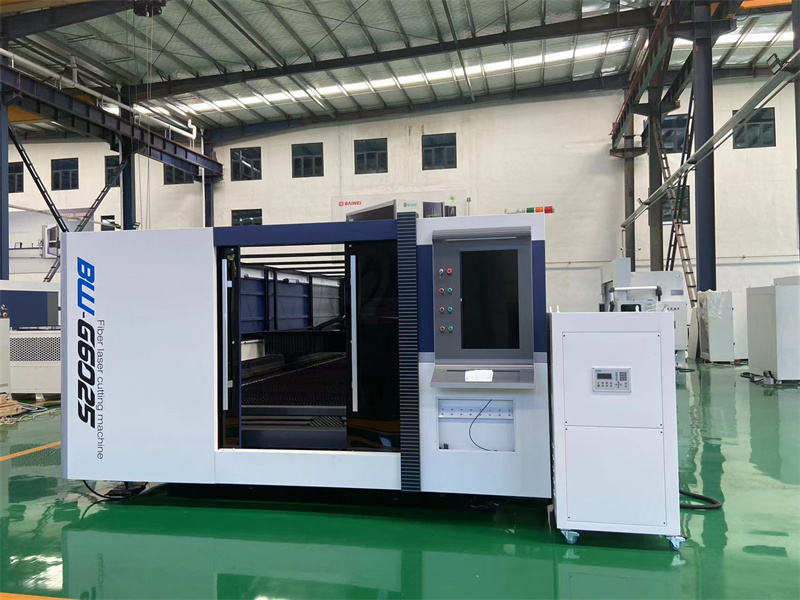

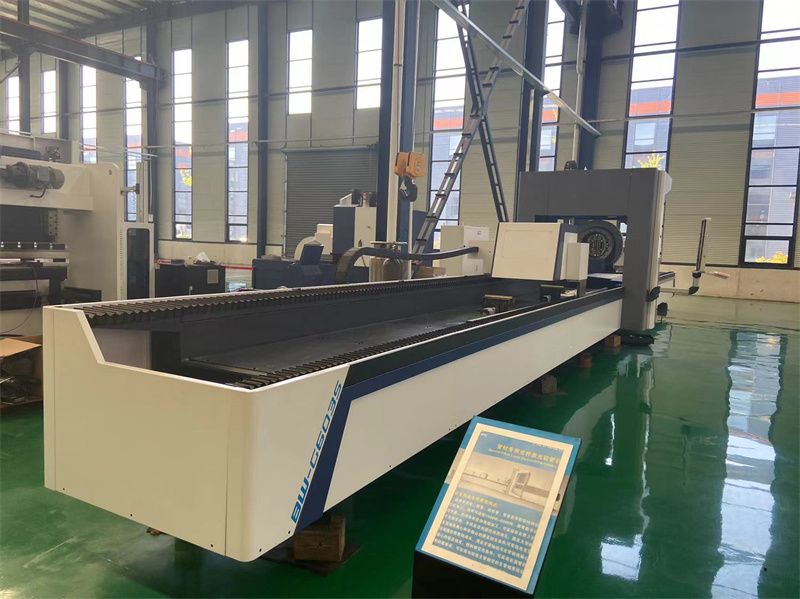

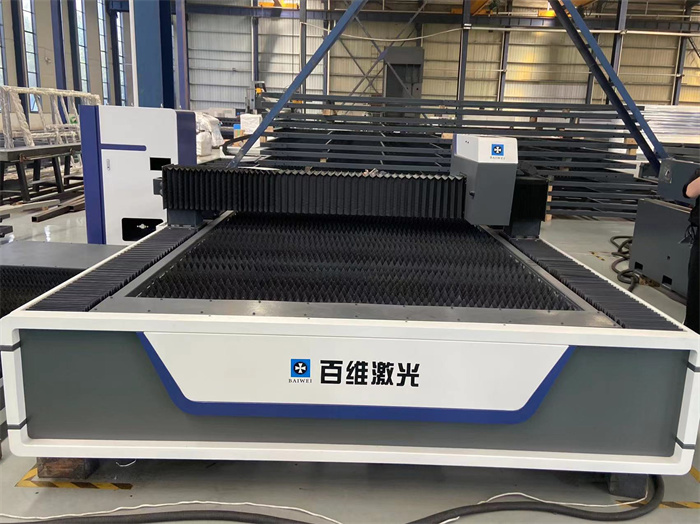

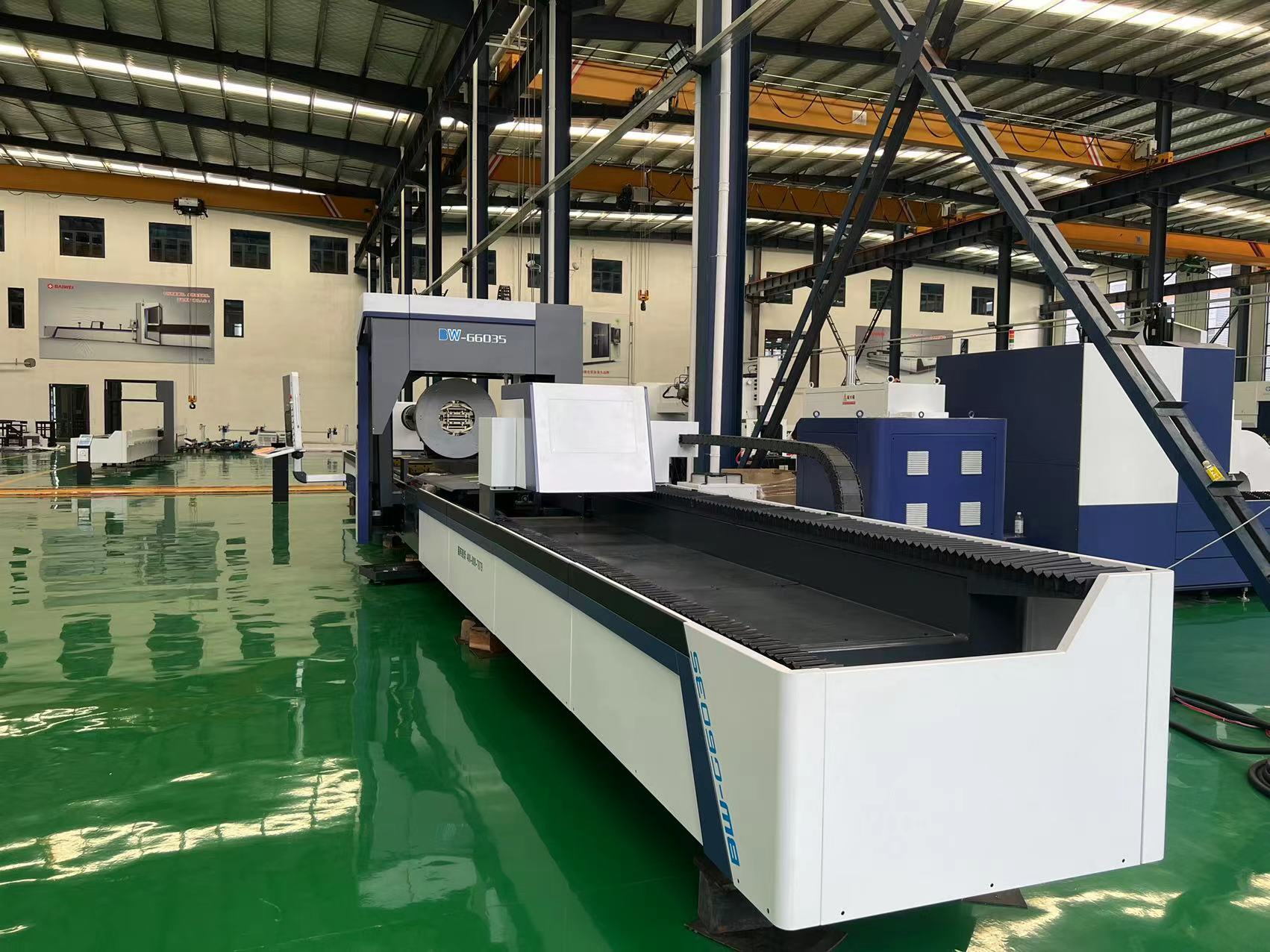

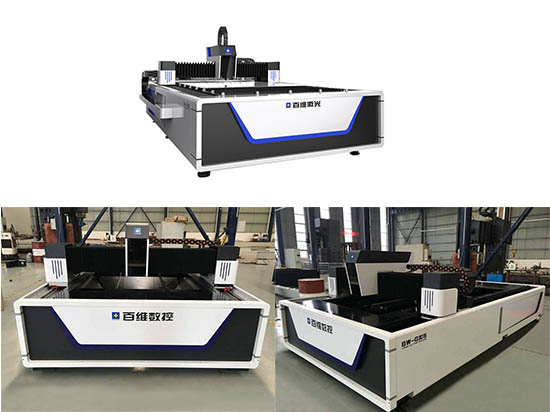

Factory Supply Attractive Price High Quality Fiber Laser Cutting Machine

FEATURES

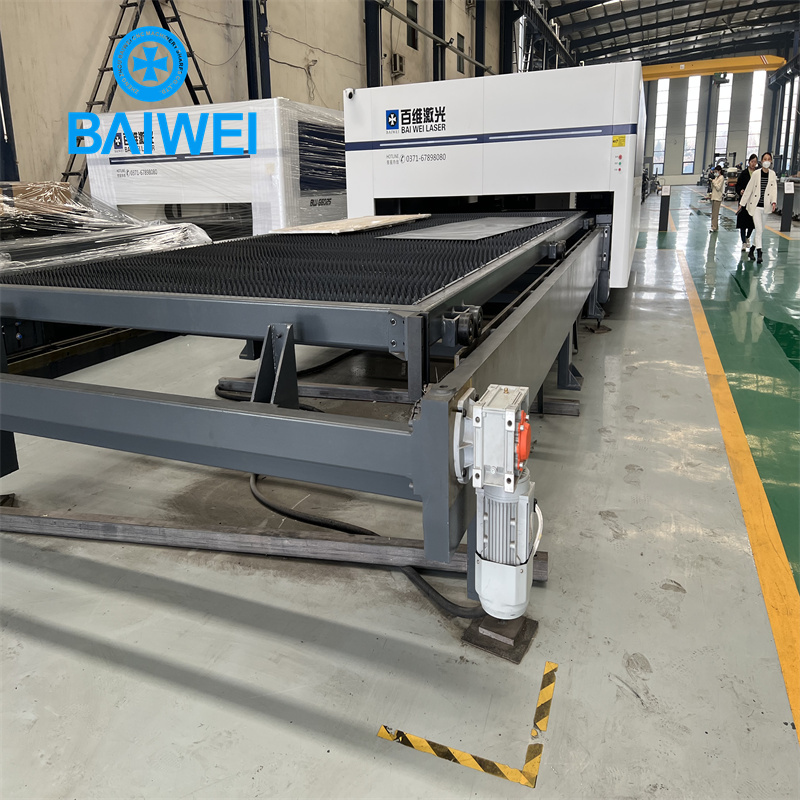

1.Heavy duty machine structure/body ensure excellent working performance for at least 20 years with no deformation.

2. Imported original fiber laser ranging from 500w to 6000w for all kinds of working requirements. Excellent working performance, lifespan can be over 100,000 hours.

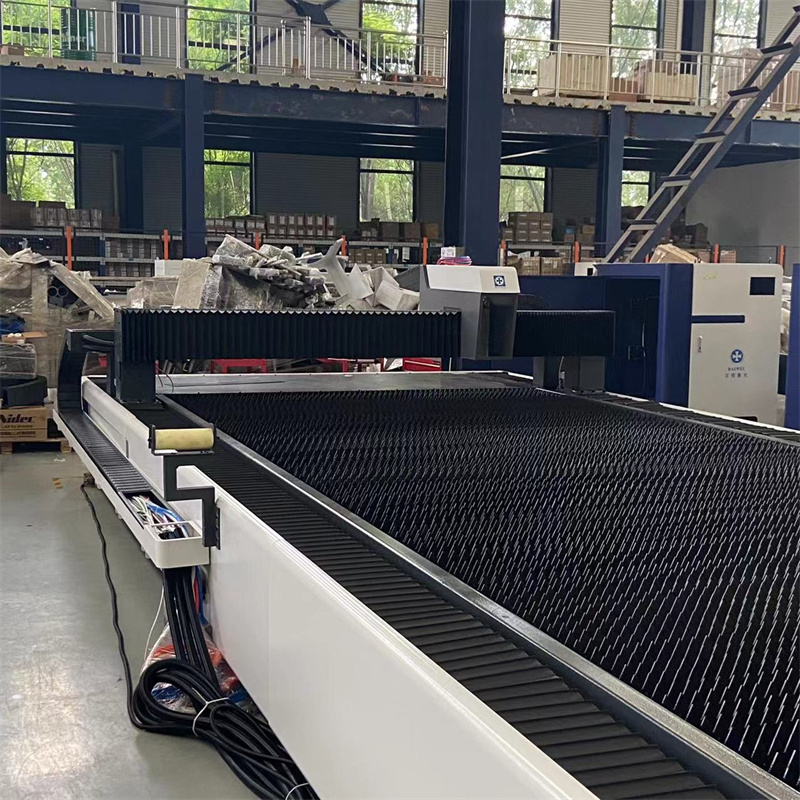

3. Gantry double driving structure, cast aluminium beam, high strength and support high running speed.

4. Open type machine structure, compact and portable, high cost performance.

5. Imported high precision transmission device perfectly work with servo system so it can guarantee excellent cutting precision and efficiency.

6. Professional software enables graphic/ text to be instantly designed or processed. Flexible and easy operation.

Advantages Of Fiber Laser Cutting Machine

(1).High Cutting Accuracy:

Laser cutting machine positioning accuracy is 0.05mm, and repeated positioning accuracy is 0.03mm.

2).Narrow Cutting Slit:

The laser beam is focused into a very small light spot, so that the focal point reaches a high power density, the material is quickly heated to the degree of vaporization, and the hole is evaporated. With the relatively linear movement of the beam and the material, the hole is continuously formed with a narrow slit, and the width of the slit is generally 0.10-0.20mm.

(3).Smooth Cutting Surface:

The cutting surface has no burrs, and the roughness of the cutting surface is generally controlled within Ra6.5.

(4).Fast Cutting Speed:

The cutting speed can reach 10m/min, and the maximum positioning speed can reach 30m/min, which is much faster than the linear cutting speed.

(5).Good Cutting Quality:

Non-contact cutting, the cutting edge is little affected by heat, basically no thermal deformation of the workpiece, completely avoid the collapse of the material formed during punching, the cutting seam generally does not require secondary processing.

(6).No Damage to Workpiece:

The laser cutting head will not contact the surface of the material, ensuring that the workpiece is not scratched.

What Is A Fiber Laser Cutter Used For?

Applicable Industries:

The fiber laser cutter can be used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, food machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, Metal external processing, kitchenware processing and other manufacturing and processing industries.

Applicable Materials:

The fiber laser cutter can be used for stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, aluminized zinc plate, pickling sheet, copper, silver, gold, titanium and other metal plates and pipes.

What Is Fiber Laser Cutting Machine Price

CNC fiber laser cutter machines of different types & models are available, so it is hard to give the exact price, generally the price ranges from $20,000 to $300,000, depending on actual model & parts. There are some factors which affect the price of fiber laser cutter machine, such as driving system, control system, brand & power of laser power, spare parts, etc, Also, some other charge & fees will have to be taken into consideration, including shipping costs, tax and customs clearance, etc.