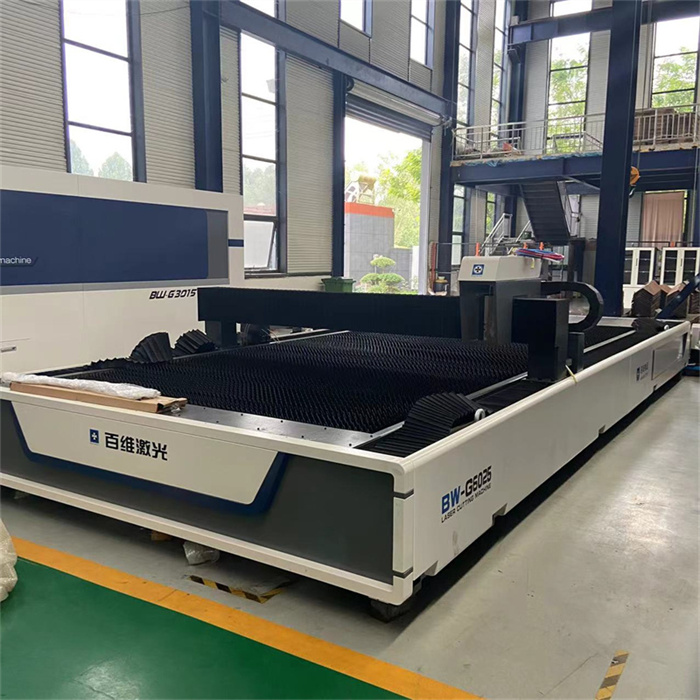

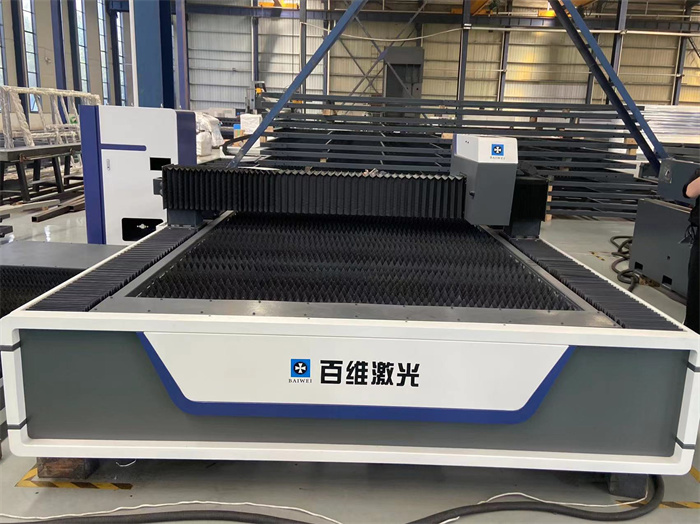

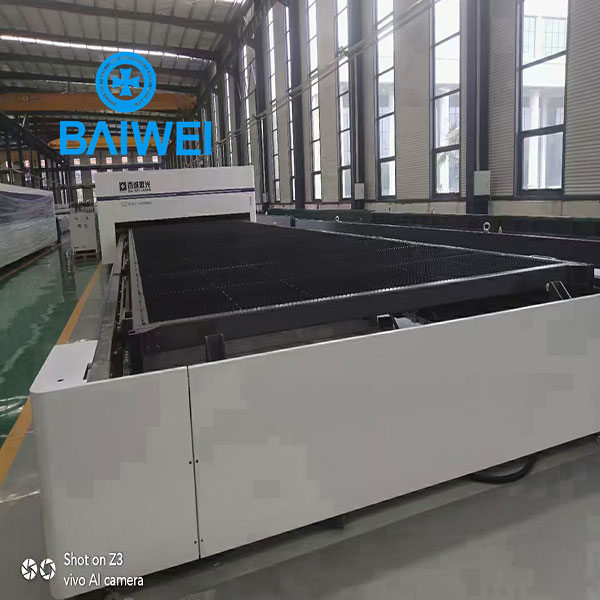

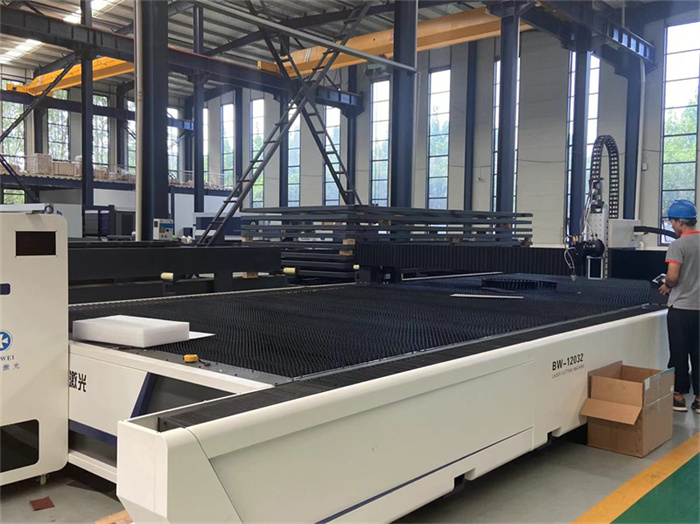

Factory high quality customized 12000w CNC Fiber Laser Cutting Machine sheet Metal Laser cutter

Parameter

Models BW-G3015 BW-G4015 BW-G4020 BW-G6015 BW-G6020 Optional

Cutting range 3000x1500mm 4000x1500mm 4000x2000mm 6000x1500mm 6000x2000mm Optional

Laser power 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw

Max moving speed 100m/min

Max cutting speed 35-80m/min

Positioning accuracy 0.03mm

Repositioning accuracy 0.02mm

Min line width 0.1mm

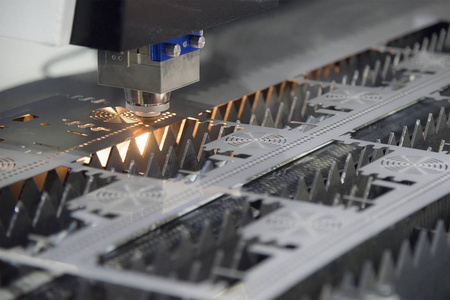

The cutting advantages of laser cutting machine in the hardware industry

The traditional hardware processing equipment uses a punch, and then cooperates with multiple processes such as polishing, shearing and bending to form the final shape. This processing efficiency is relatively low, the mold making time is long, and the cost is high. Laser cutting machine is a modern processing equipment with good economic benefits, which not only reduces the processing time of hardware products, but also makes great progress in quality, which has long-term significance for the hardware processing industry.

Good cutting quality, lower labor cost

The laser cutting machine uses the characteristics of laser non-contact processing, does not damage the workpiece, the cut product has no extrusion deformation, the processed product has good quality, no burrs, no manual re-grinding is required, unnecessary processing procedures are omitted, and labor is optimized. Strength, the matching laser chiller can effectively keep the cutting machine running stably and continuously.