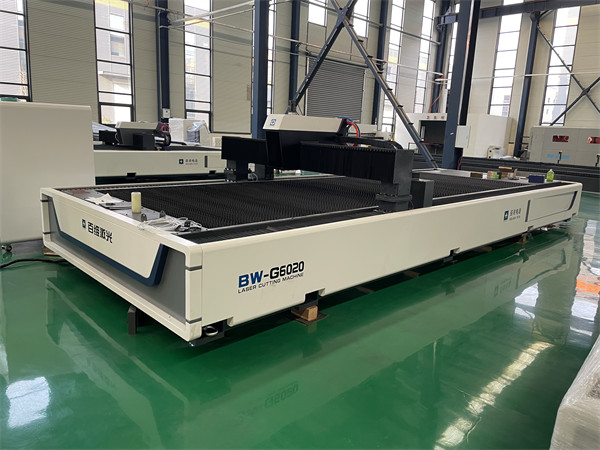

environmentally friendly metal laser cutting machine Alloy for sheet

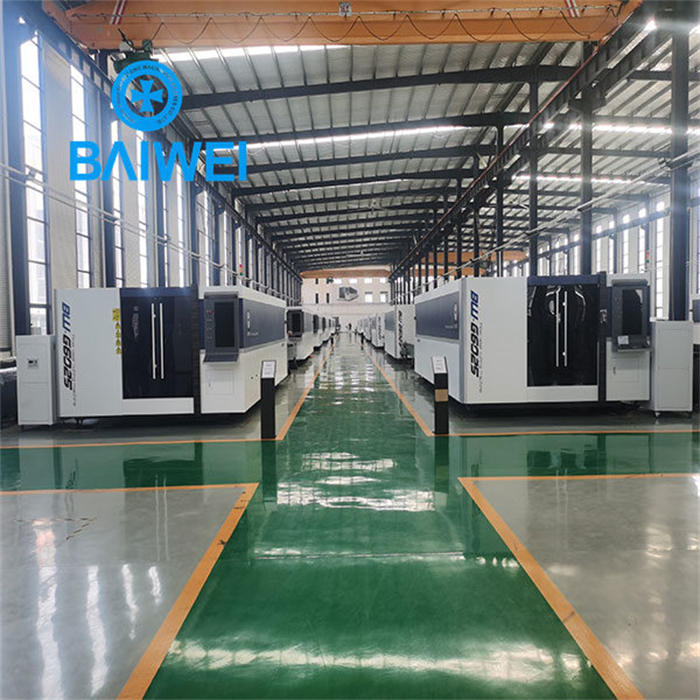

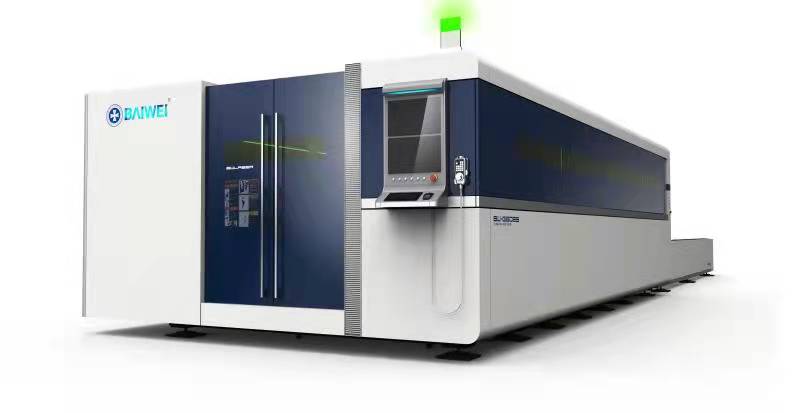

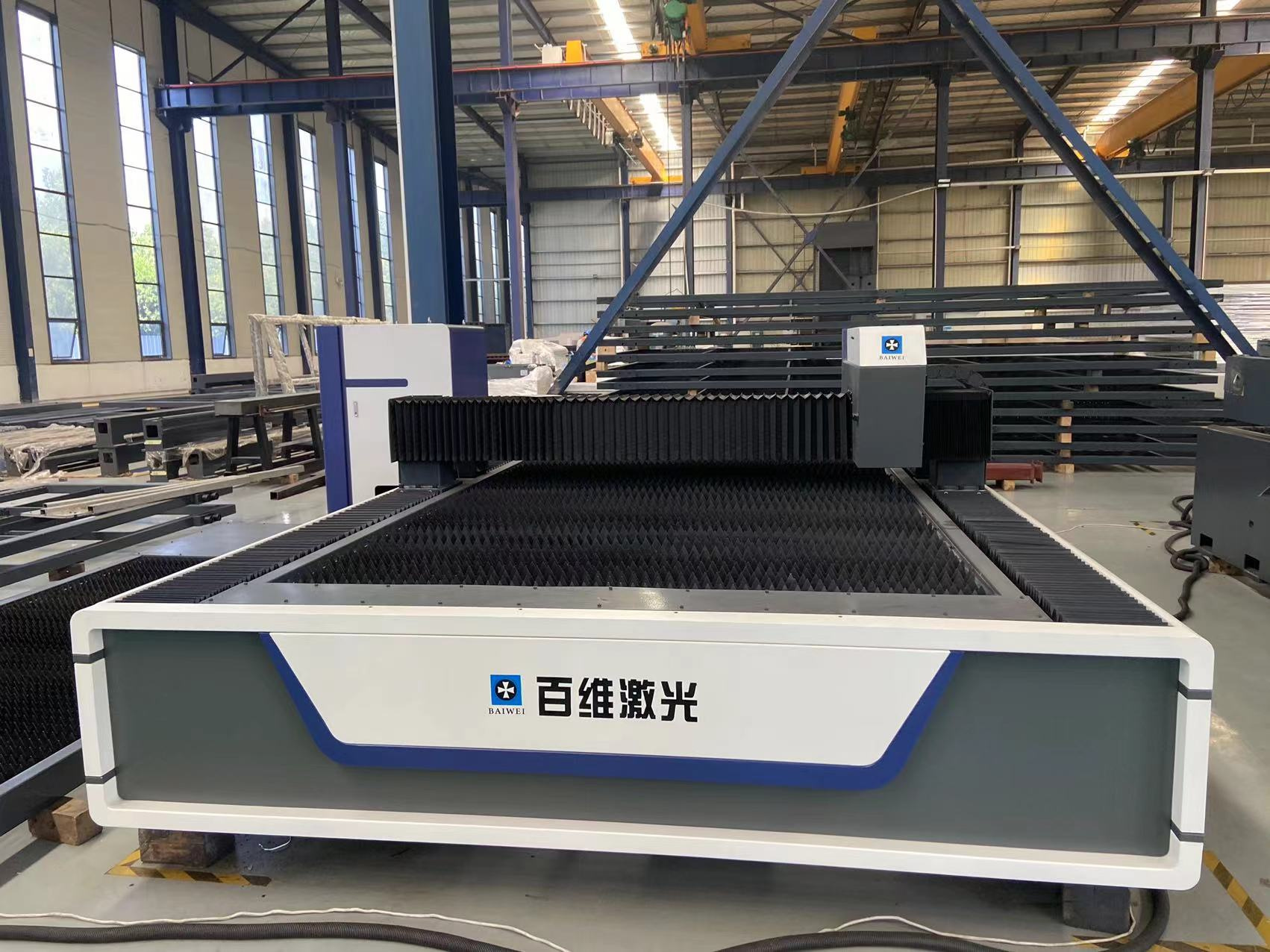

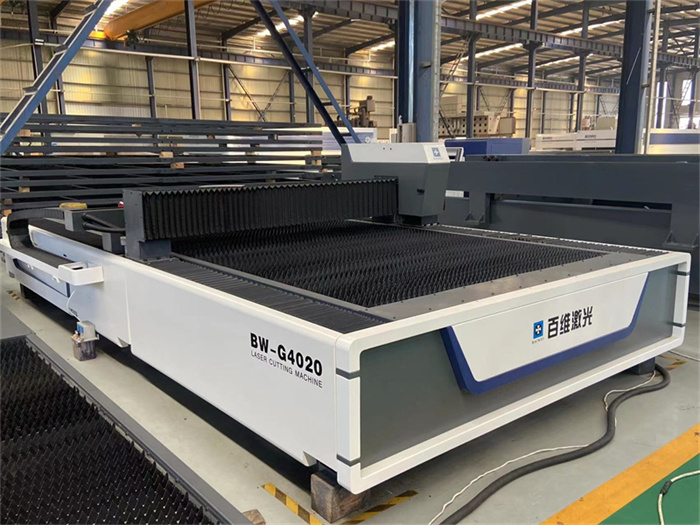

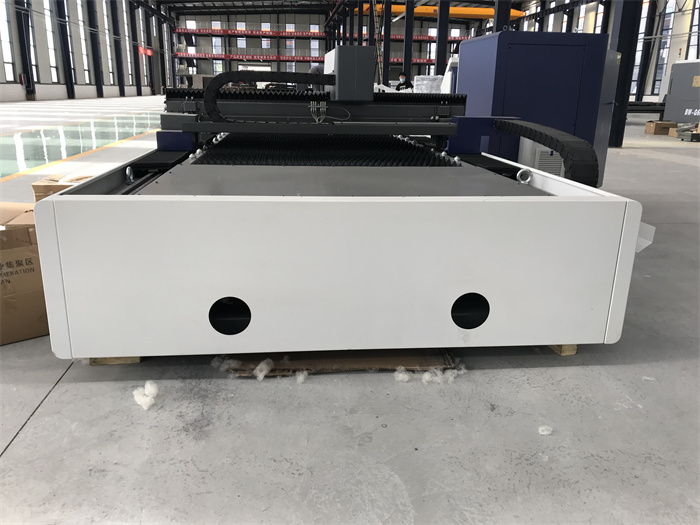

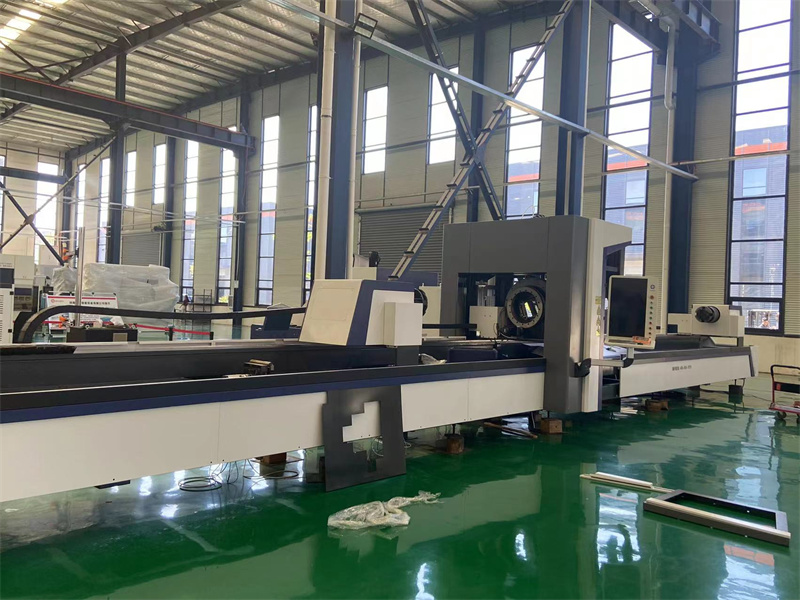

The ultra-large-format laser cutting machine has a large working format and can cut large and thick plates. The power section can be selected from 8000W-20000W, and it can process large-sized steel and a wide range of processing materials. It can be matched with high power, the thickness of the processing plate is large, the ultra-large format size can be selected, and the processing plate size is large. Flexible operation control system, humanized design, only for better cutting experience for users.

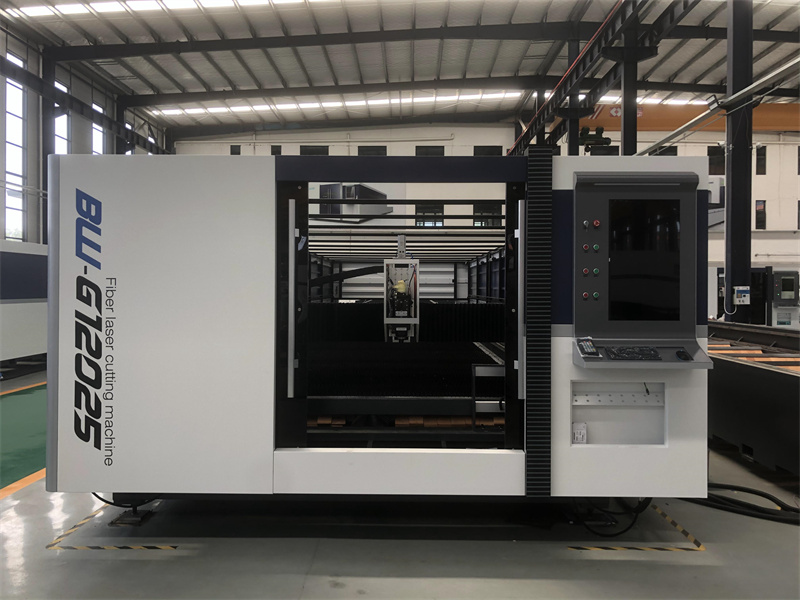

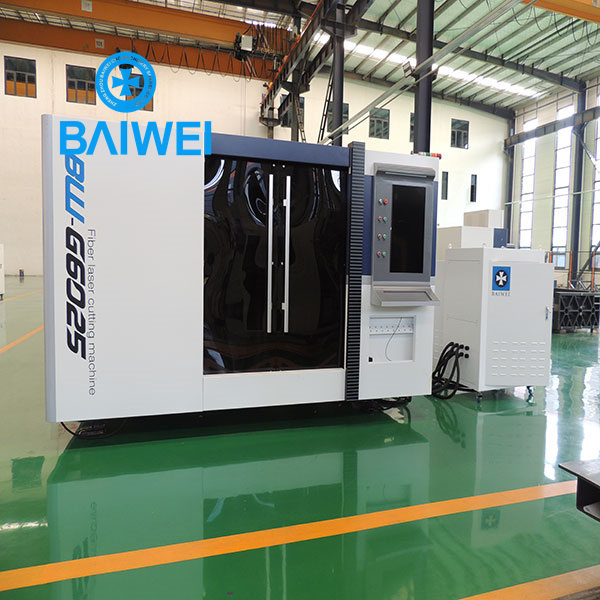

In the production process of hardware accessories, fiber laser cutting machine is needed, which has high cutting quality and fast speed.Model:BW-G12025

Laser Power:500w/1kw/2kw/4kw/6kw/8kw/10kw/12kw

Max.cutting Speed:35-80m/min

Positioning accuracy:0.03mm

Re-position accuracy:0.02mm

Min.line Width:0.1mm

One of the biggest benefits of using a fiber laser cutting machine is the low cost of use and low maintenance, which is very beneficial for companies that already have multiple machines. Spend less time on maintenance and more time on cutting products. In terms of cost of use, since the cutting efficiency is significantly ahead of other processes, the relative cost will be much lower, which is more conducive to the development of small and medium-sized enterprises.The new generation of fiber laser cutting machines are all computer numerical control and remote operation. After importing the cutting drawings, the work will be performed automatically. Basically, all actions can be completed with one or two keys. It is very simple and reduces labor costs. There is automatic loading and unloading, which is more convenient.

One of the biggest benefits of using a fiber laser cutting machine is the low cost of use and low maintenance, which is very beneficial for companies that already have multiple machines. Spend less time on maintenance and more time on cutting products. In terms of cost of use, since the cutting efficiency is significantly ahead of other processes, the relative cost will be much lower, which is more conducive to the development of small and medium-sized enterprises.