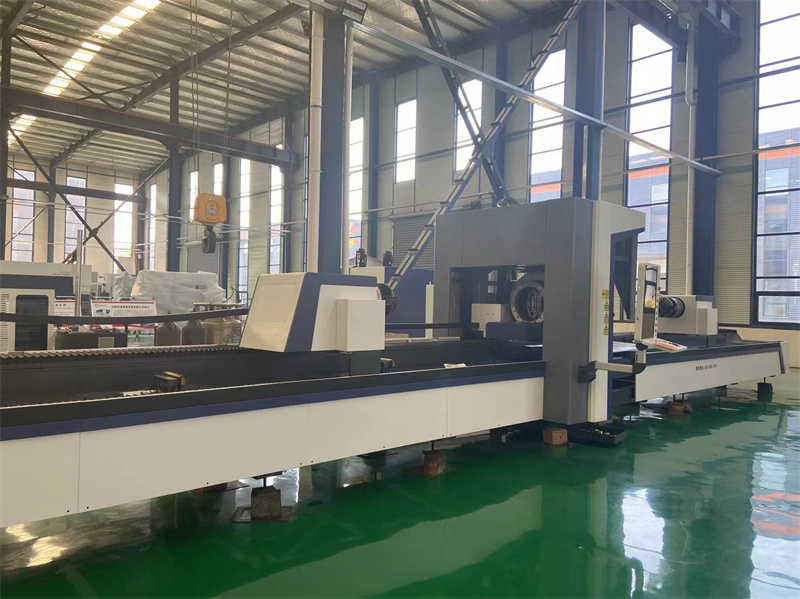

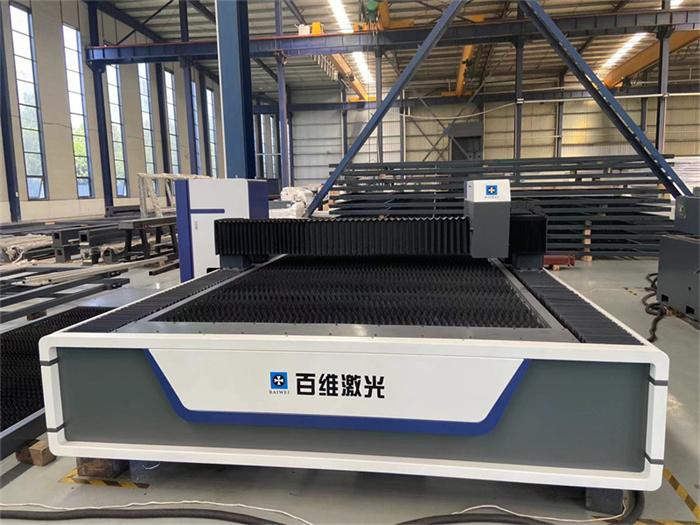

Environmental BW-G6025 closed type fiber laser cutting machine for steel sheet

BW-G6025 closed type fiber laser cutting machine adopts the most advanced German IPG fiber laser, with extremely high photoelectric conversion efficiency. The performance of BW-G6025 closed type fiber laser cutting machine is stable, and the service life of key components can reach 100,000 hours.

Laser Source:IPG/Raycus/Nlight

Laser Power:6kw/8kw/10kw/12kw/15kw/20kw (Optional)

Processing Surface:6000*2500mm/6000*2000mm/4000*2000mm (Optional)

Position Accuracy X, Y and Z Axle:¡À0.03MM

Cutting Thickness:Carbon Steel 0.5MM-30MM, Stainless Steel 0.5MM-16MM

¡¡

What will happen to the future of fiber laser cutting machines?

When it comes to high-power fiber laser cutting machines, the room for improvement is huge and just around the corner. The future of this technology can be easily summed up in a few words-“Fiber laser cutting technology is reviving because new models are better constructed and more efficient.”

Automation is always the way forward. Although fiber cutting does see a certain degree of autonomous cutting, improving the machine to make it cut on its own is a huge benefit for the industry.

Automation is very useful for any manufacturer because it can reduce labor costs. Not only that, but it also saves people from having to work on these machines, but instead focuses on other areas. Manufacturers can simply hire experts to maintain and repair them instead of operating them when they fail.