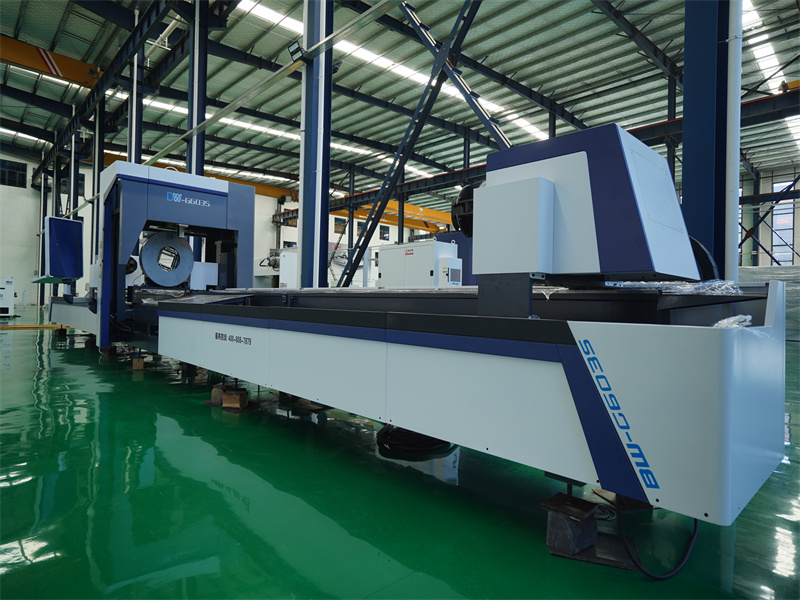

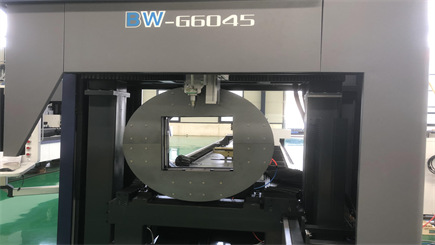

Energy-saving closed fiber laser cutting machine direct factory

The enclosed fiber laser cutting machine can load and unload while processing, which is convenient, fast and time-saving. The enclosed fiber laser cutting machine is mainly used for cutting pickling plates, galvanized plates, copper, etc.

Laser Power:12kw/15kw/20kw/30kw (Optional)

Laser Source:IPG/Nlight/Raycus

Processing Surface (L*W):13500*3200mm/13500*2500mm/12500*3200mm/12500*2500mm/10000*3200mm (Optional)

Position Accuracy X, Y and Z Axle:+0.03MM

Cutting Thickness:Carbon Steel 0.5MM-40MM, Stainless Steel 0.5MM-40MM

At present, laser cutting machines can be divided into three types based on lasers: optical fiber, CO2, and YAG. However, with the continuous development of technology, the cutting efficiency of YAG cutting machine is low, the photoelectric conversion rate is high, and the use cost is relatively high, so it has gradually withdrawn from the historical stage.

Therefore, CO2 and fiber lasers have different application fields and different costs, so customers can choose according to their actual needs.

Fiber lasers cannot cut non-metals, including wood, plastic, leather, cotton and linen fabrics. If the workpiece material that needs to be processed is exactly non-metal, then the fiber laser can only be dropped, and not the CO2 laser.

Most automotive interior parts are non-metallic materials. The high-precision robot + CO2 laser processing system is used to cut the space and the curved surface. Such a processing system needs to solve the problem of laser beam transmission between the robot joints.

Here, in order to facilitate the comparison of the cost difference between the two lasers, only the cost of the three parts consisting of electricity, consumables, and medium gas is calculated. The costs of these three parts are different; labor, depreciation, site, cutting gas, etc. For a laser, the cost is the same and it is not calculated.

Both lasers require a huge amount of power. The fiber laser has an electro-optical conversion efficiency of about 30% and a CO2 laser about 10%. In the case of a 3000 W laser, a fiber laser consumes about 10 kW of power while a CO2 laser consumes about 30 kW. The electricity price is 0.1 USD/degree and the load factor is 70%. The costs are 0.7usd/hour and 2.1 usd/hour respectively.

In addition, due to the different efficiencies, the heat generated by the two lasers is different, and the required water cooler specifications (cooling capacity) are also different. The power consumption of the water cooler required for the fiber laser is 13 kW, and the power consumption of the water cooler required for the CO2 laser is 18 kW. With electricity prices at 0.1usd/degree and 70% of the total load, the costs are 0.9usd/hour and 1.28usd/hour respectively.

In the daily use process, the materials used for the fiber laser cutting machine (hereinafter referred to as the optical fiber cutting machine) include the focusing lens, the ceramic body, the nozzle, the protection mirror and the like, and the cost is about 0.3usd/hour.

In addition, according to the statistics of the past four years, the laser module and beam expander have their service life, which respectively generate about 0.4usd / hour, 0.1usd/ hour cost (in particular, the smallest unit ROFIN fiber laser needs to be replaced is the semiconductor module , cost about 0.1usd / hour).

Cutting tools using CO2 laser (hereinafter referred to as CO2 cutting machine) need to consume materials: focusing mirror, ceramic body, nozzles, mirrors, etc., cost about 0.25usd / hour.

Fiber lasers do not require a dielectric gas; CO2 lasers require the use of a dielectric gas to generate the laser, which costs about 0.1usd /hour.

In addition, CO2 lasers are routinely inspected every 3000 hours, and depth inspections are performed every 6000 hours, and a cost of about 0.2usd/hour occurs.

In summary, the use cost of fiber laser is about 24 yuan/hour, and that of CO2 laser is about 3.83usd/hour, a difference of 1.43usd/hour. According to the use of 10 hours per day, the daily cost difference is 14.3usd.

There is some exaggeration in the market about the difference in the use of the two lasers.

Incidentally, the transmission medium of the fiber laser is an optical fiber, and the light beam is enclosed in the optical fiber and “curve propagation” is not affected by the external environment. The CO2 laser transmission medium is air, which travels in a straight line and changes its transmission direction by a mirror. It is susceptible to the external environment and may require the maintenance of these mirrors, thus slightly increasing the cost of use.

The above is a comparison of the two lasers, we can choose according to the actual situation, of course, Baiwei laser dedicated to provide you with professional products and services, more information please consult us.