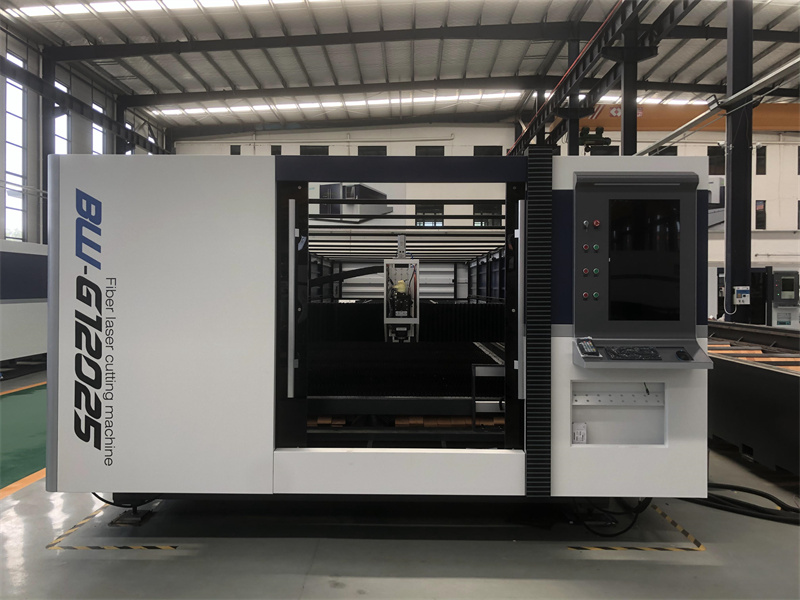

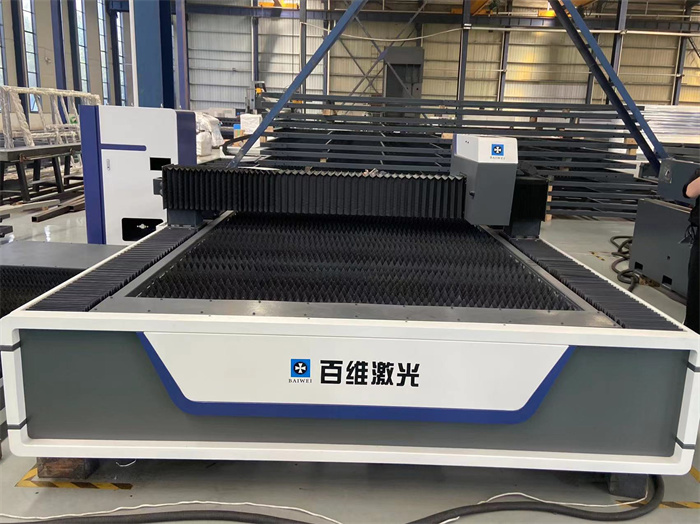

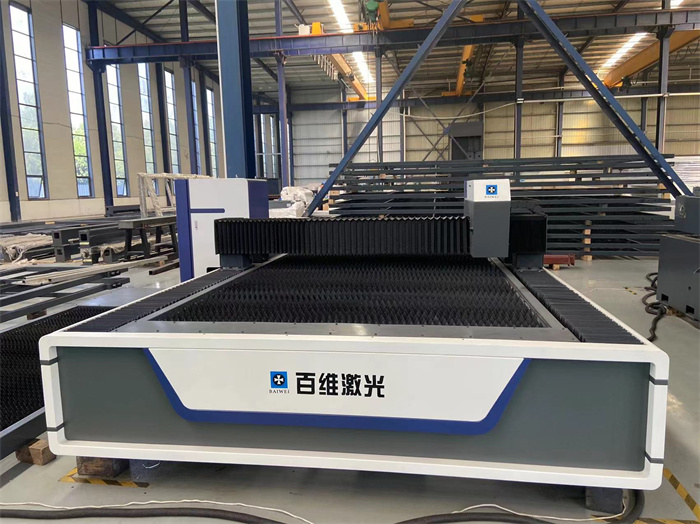

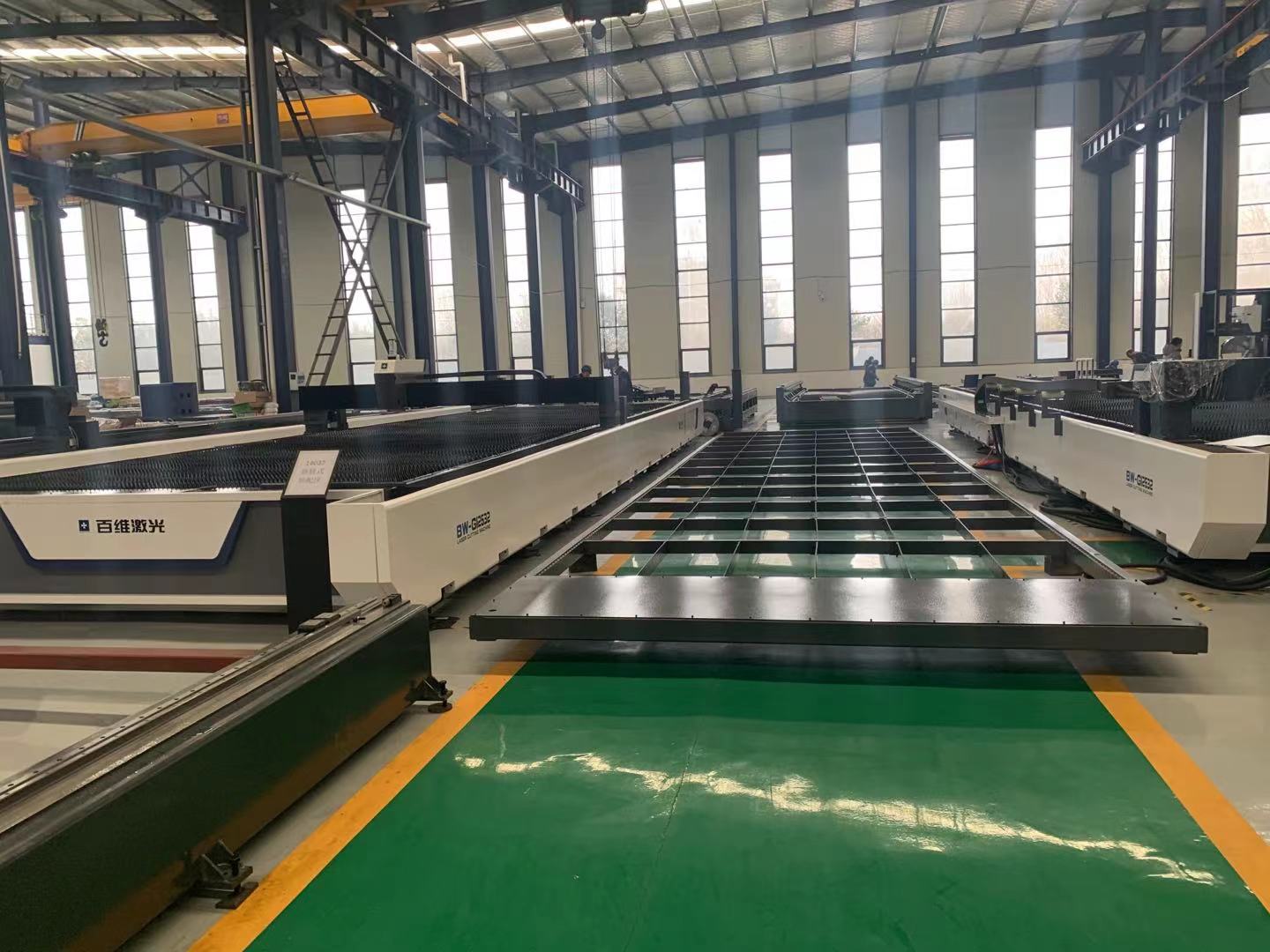

Easy-operated open type fiber laser cutting machine for sale

Model: BW-G3015

Cutting range: 3000x1500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 100m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

How do I use a laser cutting machine to cut high-quality workpieces?

When using a laser cutting machine to cut thicker or higher precision parts, the cutting process requirements are relatively high, so what are the factors that affect the cutting quality of the laser cutting machine?

1. The thickness of the metal material

With the development of fiber optics technology, the wattage of fiber laser cutting machines is also increasing, and the thickness of the metal that can be cut is also increasing. The thickness of the metal sheet to be cut must correspond to the relative wattage of the laser cutting machine to achieve better results.

2. Cutting speed

Cutting speed too fast or too slow will affect the cutting quality. The laser cutting speed needs to be determined according to the material and the thickness.

3. The roughness of the material surface

Laser cutting machine processing is not limited by the shape of the material, but the surface roughness of the material determines the quality of the cutting. The smoother the material surface, the better the cutting effect. The smoother the material surface, the better the cutting effect. Therefore, in order to maintain the cutting quality, try to choose materials with smooth and rust-free surfaces.

4. Cutting focus

The position of the focus is one of the key points of cutting quality. Only with accurate focus can the ideal cutting be achieved.

60.Why should we retrofit from a CO2 laser cutting machine to a fiber laser?

1. Compare from the structure of laser equipment

In carbon dioxide laser cutting technology, carbon dioxide gas is the medium that generates the laser beam. However, fiber lasers are transmitted through diodes and fiber optic cables. The fiber laser system generates a laser beam through multiple diode pumps, and then transmits it to the laser cutting head through a flexible fiber optic cable instead of transmitting the beam through a mirror. This has many advantages, the first is the size of the cutting bed. Unlike gas laser technology, the reflector must be set within a certain distance. Unlike fiber laser technology, there is no range limit. Moreover, the fiber laser can even be installed next to the plasma cutting head of the plasma cutting bed. There is no such option for CO2 laser cutting technology. Similarly, when compared with a gas cutting system of the same power, the system is more compact due to the ability of fiber bending.

2. Compare from the conversion efficiency of electro-optics

The most important and meaningful advantage of fiber cutting technology should be its energy efficiency. With the complete solid-state digital module and single design of the fiber laser, the fiber laser cutting system has a higher electro-optical conversion efficiency than carbon dioxide laser cutting. For each power supply unit of the carbon dioxide cutting system, the actual general utilization rate is about 8% to 10%. For fiber laser cutting systems, users can expect higher power efficiency, about 25% to 30%. In other words, the overall energy consumption of the fiber cutting system is about 3 to 5 times less than that of the carbon dioxide cutting system, which improves the energy efficiency to more than 86%.

3. Contrast from the cutting effect

Fiber laser has the characteristics of short wavelength, which improves the absorption of the cutting material to the beam, and enables cutting such as brass and copper as well as non-conductive materials. A more concentrated beam produces a smaller focus and a deeper depth of focus, so that the fiber laser can cut thinner materials quickly and cut medium-thick materials more effectively. When cutting materials up to 6mm thick, the cutting speed of a 1.5kW fiber laser cutting system is equivalent to that of a 3kW carbon dioxide laser cutting system. Because the operating cost of fiber cutting is lower than that of a common carbon dioxide cutting system, this can be understood as an increase in output and a reduction in commercial costs.

4. Compare from maintenance cost

In terms of machine maintenance, fiber laser cutting is more environmentally friendly and convenient. The carbon dioxide gas laser system needs regular maintenance; the reflector needs maintenance and calibration, and the resonant cavity needs regular maintenance. On the other hand, the fiber laser cutting solution requires almost no maintenance. The carbon dioxide laser cutting system requires carbon dioxide as the laser gas. Due to the purity of carbon dioxide gas, the resonant cavity will be contaminated and needs to be cleaned regularly. For a multi-kilowatt carbon dioxide system, this item requires at least US$20,000 per year. In addition, many carbon dioxide cutting requires high-speed axial turbines to deliver laser gas, and turbines require maintenance and overhaul.