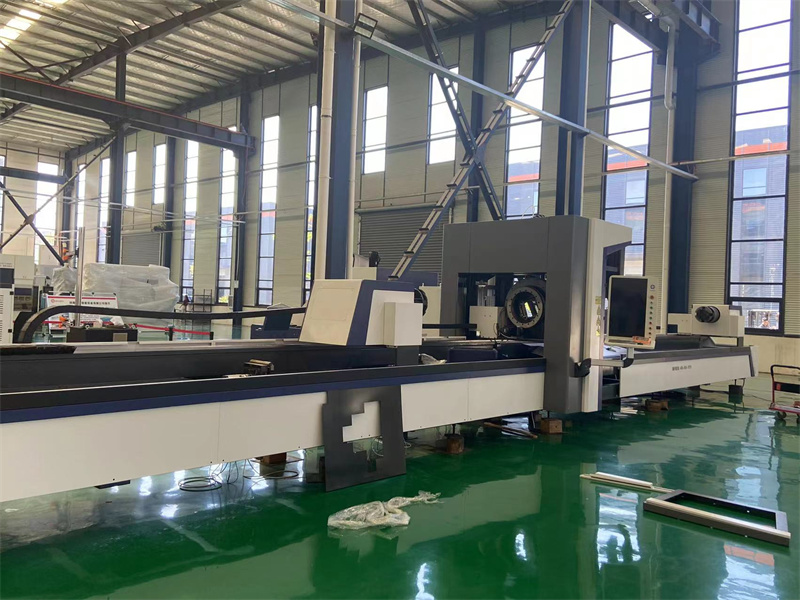

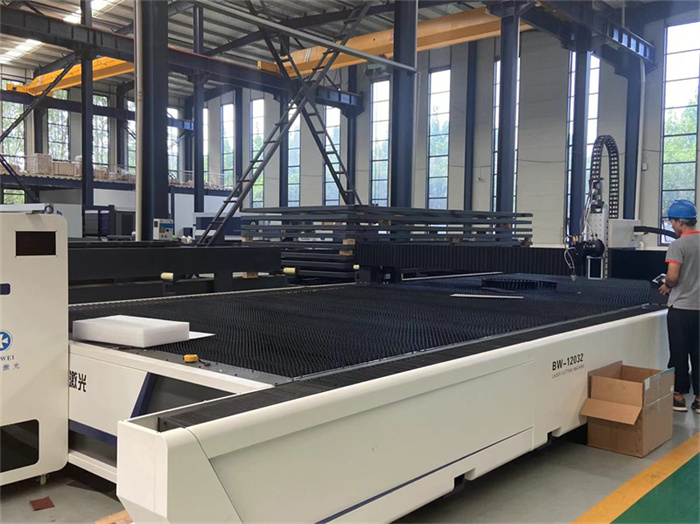

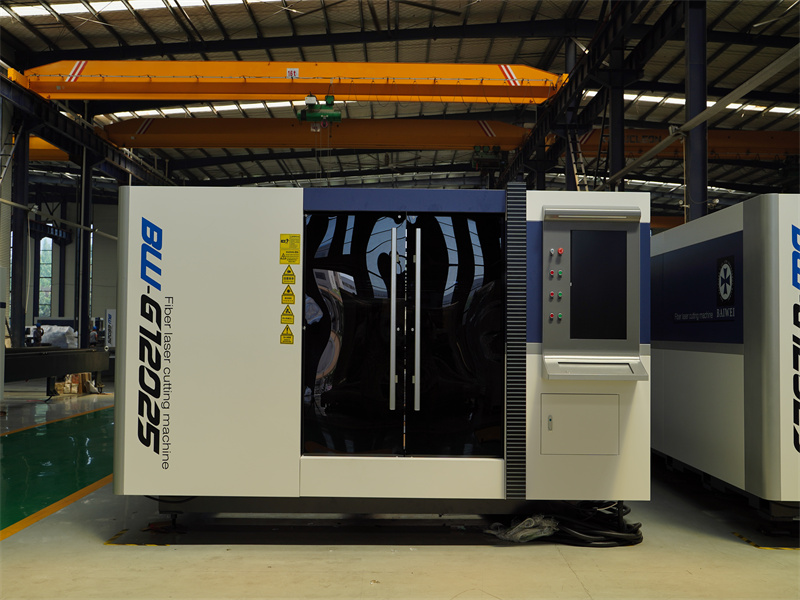

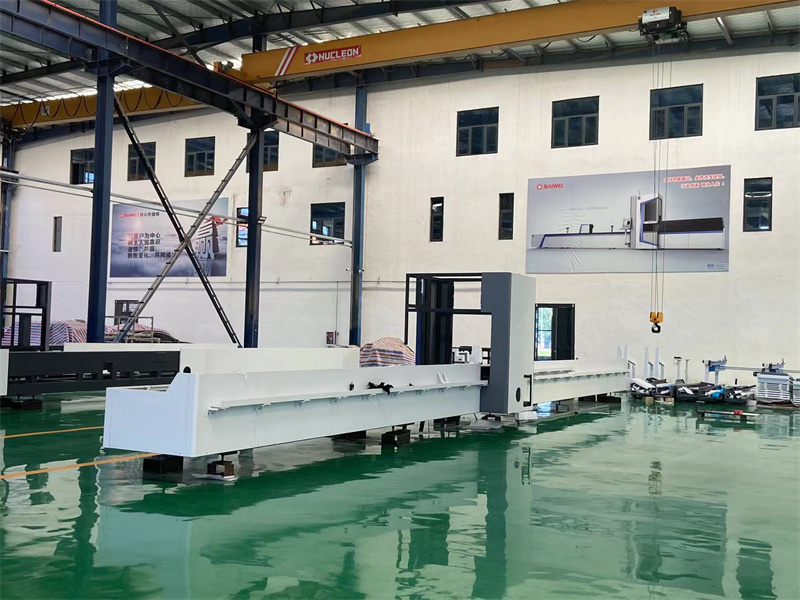

Durable and timeproof professional tube laser cutting machine

The heat-affected zone of the professional tube laser cutting machine is very small, and there is almost no thermal deformation. Oxidation-free for professional tube laser cutting machine can produce high-quality, more consistent parts.

Laser Type:Fiber Laser Source

Max. Output Power:500W/800W/1000W/1500W/2000W

Effective Pipe Cutting Diameter:¡Ü220MM

Effective Pipe Cutting Length:3000MM/6000MM

Workable Axis Positioning Accuracy:¡Ü¡À0.05MM

What is fiber laser cutting?

Lasers amplify light by passing it through a medium that increases its power exponentially. The most common cutting laser uses primarily CO2 gas (though includes other gases as well.) The beam bounces between a pair of mirrors, each time it passes through the gas, it is amplified. One mirror allows some of the beam to pass through, that is the beam we use to cut or engrave with. CO2 lasers create a beam at 10,600nm which can be absorbed by many organic materials like wood, paper, plastic, etc. As a result, at sufficient power, this beam can cut or mark (burn) those materials.

A YAG laser uses a high intensity light source like Xenon and passes it through a crystal rod composed of neodymium-doped yttrium aluminum garnet and in doing so, is converted to a beam of light in the 1064nm range. This is a much different wavelength, and as a result, will not cut the materials listed above, but is commonly used in surgical applications, laser range finders, and can mark metals without a special coating, or even cut metals at sufficient power.

Fiber optics are made by starting with a rod of glass or crystal that light can pass through. The rod is placed inside a tube of glass that has a different index of refraction. These are both lowered into a furnace that melts them together and it is stretched out into tiny fibers that retain the same rod within a tube construction. Because of the difference in refraction, light entering the middle portion does not leak out the sides, but is instead reflected back into the fiber, allowing it to travel long distances.

A Fiber laser is basically a YAG laser, but instead of the light passing through a short rod of the special material, it passes through a fiber optic made of it. This provides the same amplification and wavelength of light, but also allows the light to be routed from the laser source to the head of the laser without it traveling through air using mirrors as is typical of other types of lasers. Since both air and mirrors result in power loss, the beam remains stronger at the output, and machines can be designed without worrying about maintaining a clear path for the beam.