Do you now how much does a fiber laser cutting machine cost?

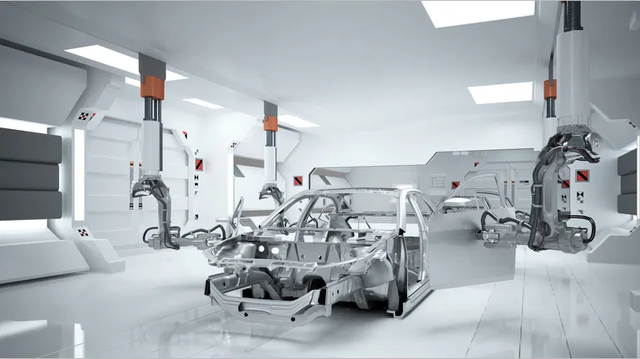

Fiber laser cutting machine is a kind of CNC laser metal cutting equipment with high quality, high speed, high precision and high efficiency. Fiber laser cutters are suitable for all kinds of metal fabrication, which will be your good metal working partner.The best fiber laser cutting machines are equipped with different laser powers (2000W, 3000W, 4000W,6000w, 8000w) for cutting metal sheets and plates, including stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials with different thickness.

The laser emitted by the fiber laser generator is focused by the optical path system into a fiber laser beam of high power density. The fiber laser beam is irradiated onto the surface of the work,piece to bring the work piece to a melting point or boiling point, while the high-pressure gas coaxial with the fiber laser beam blows away the molten or vaporized material. As the fiber laser beam moves relative to the work piece, the material is slit finally, thereby achieving the purpose of cutting.

Do you now how much does a fiber laser cutting machine cost?

At first, it’s necessary to know your working terms well. What types of materials the machine will cut? Are there be a lots of materials to be cut that you should buy the machine? Maybe the outsourcing would be better solution? The other important point is a budget. Even if you have not enough money, you can use different ways of financing. There are many grant sources which can make your financial situation better.

If you would like to analyse cutting precision, the fiber laser is the best technology. It is even 12 times better than plasma cutting and 4 times better than water cutting. So, the fiber laser cutting will be the best solution for the companies that need get masterpiece of precision, even for the most complicated elements. The one of reason of this level of precision is very narrow cutting gap. The fiber laser technology lets also get perfect shape of small holes.

Another advantage of laser cutting machines is the best cutting speed. However the water cutting is also very precise but it takes much more time. The fiber laser cutting machines achieves even 35 m/min speed. It ensures immeasurably better efficiency.

It’s also important to pay attention to the slag, that is set on the element after the cutting process. It makes necessary to waste more time for cleaning. It generates also more costs and more time for preparing final product in this way. The slag is particularly inherent during the plasma cutting process.

If you still have questions, please feel free to contact with me!