Do you know the difference between cast iron machine table and heavy plate welding table

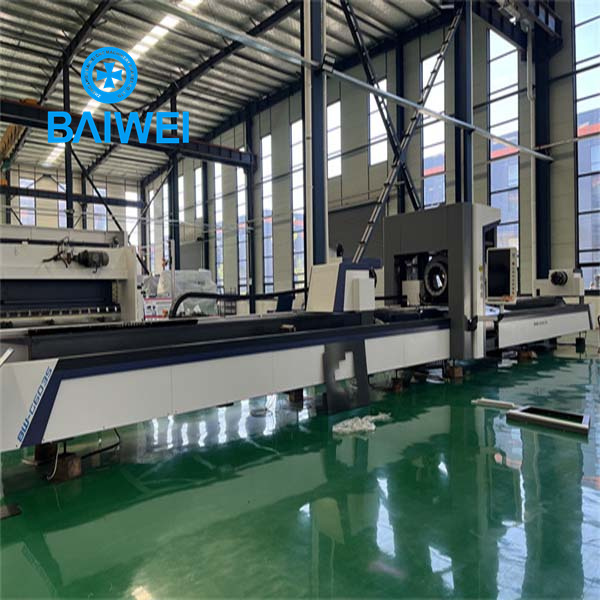

There are three popular machine table in this industry. Heavy plate welding table, cast iron machine table and tube welding table.

As tube welding table is no guarantee of precision, only small factory who pursue profit will use this model.

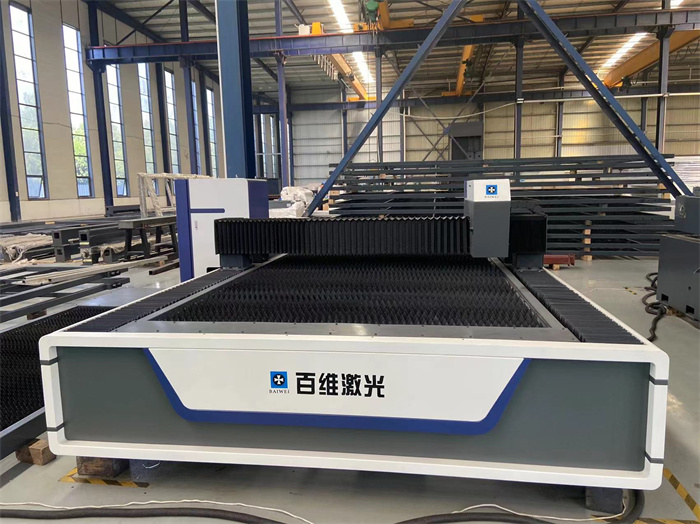

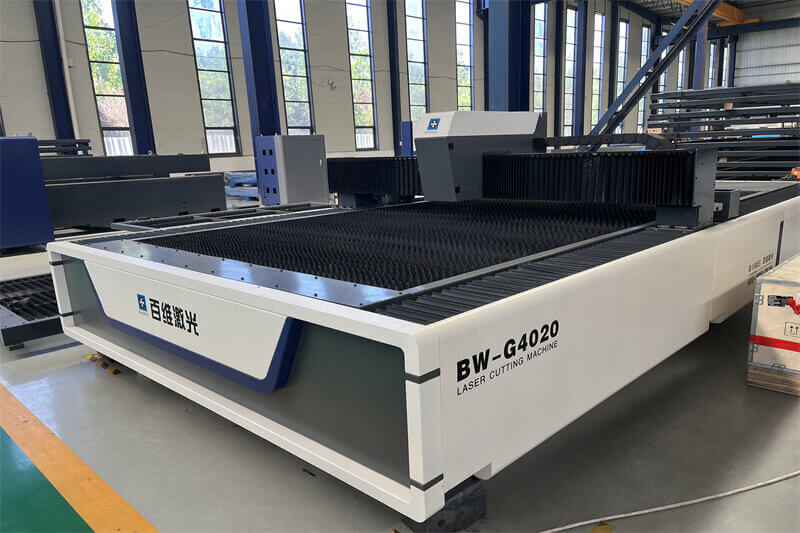

All Baiwei machine table use heavy plate welding table, we special has a fully production line to process our machine table and make sure each step is under strict quality control.

As a buyer, you may heard about plate welding table and cast iron machine table. In my this article, I just want to share cast iron bed and welding machine bed with you.

The advantages of casting bed is integrally formed, looks firm and beautiful. But there is some shortcomings of casting bed you may don’t know.

1. High defect rate over 30%: As the bed cost is high, so some factory will also sell unqualified machine bed to customers, so no one can guarantee the machine bed for you is qualified.

2. Easy broken: During the casting iron process, there will be some sand, cracks, cold lap in the inner side of machine bed. This defect is unavoidable unless you personally produce machine bed and supervise every details.

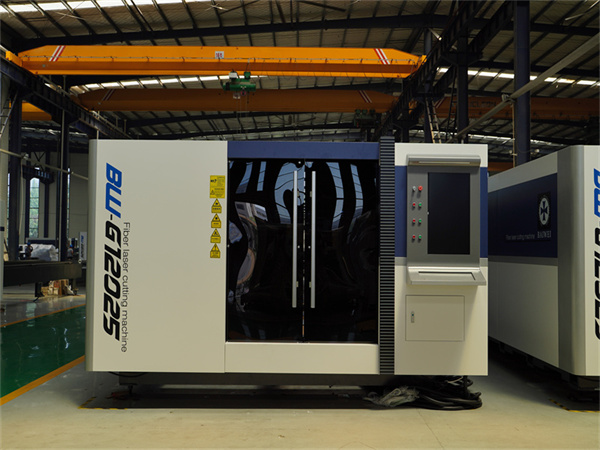

3.Not suitable for high speed operation equipment: fiber laser machine speed is over 3m/min,especially when exchange table works with high acceleration,which will bring the resonance of the bed.

Once the resonance generated is greater than the force machine bed will bear, the bed will broken and not repair.

That’s why the leading manufacturer as Trumpf Laser, Hans Laser all use welding machine bed instead of cast iron bed. It means the welding bed technology is mature, stable and high performance.

Machine bed weight is an important way to judge a real cast iron bed:

Our factory use welding machine bed, the inner side have reinforced metal, but still some part is empty. But our bed weight is 9,000kg for G3015 closed type with exchange table .

For a real cast iron bed, the inside of bed is solid, so their weight should be at least 1.5 times or double times than us.

Difference between Common Configuration and some factory design brand:

In this industry, 80% supplier will choose common configuration like Cypcut control system, Swiss Raytools Laser cutting head, which is used and recognized by many customers from all over the world.

So it’s easy to repair and buy wearing parts all over the world.

But for factory customized brand, you can only rely on this factory to repair or provide wearing parts for you. It’s hard to get timely service.

(It’s similar when people buy phone, people will choose IOS or Android software, instead other brand)

Cast iron bed with over 30% defect rate, it’s easy broken during machine operation process. That’s why most customers prefer welding bed.

For general machinery, most customers choose standard configuration instead of customer brands for get best global service