Home » Fiber Laser Cutting Machine » Consumption And Longer Working Life Due To Using The New Generation IPG Fiber Laser Source Baiwei Fiber Laser Cutter, Better Laser Beam Quality

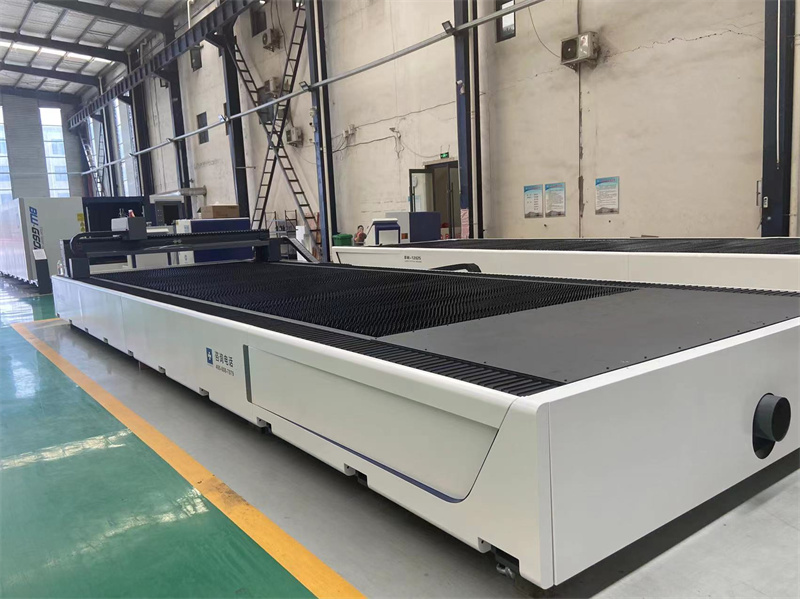

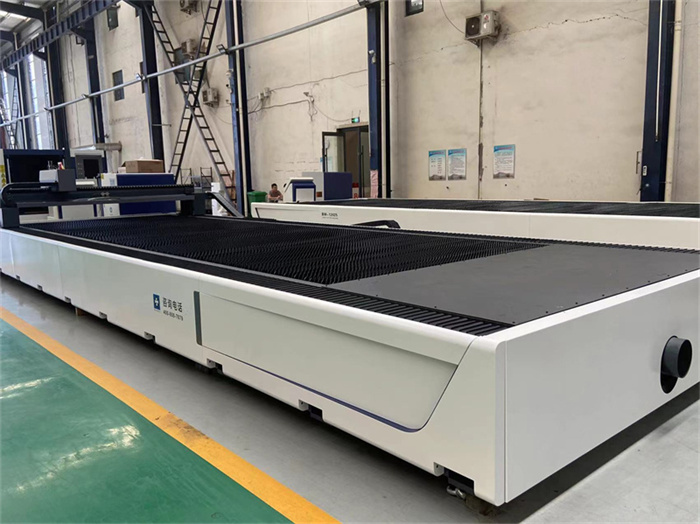

Consumption And Longer Working Life Due To Using The New Generation IPG Fiber Laser Source Baiwei Fiber Laser Cutter, Better Laser Beam Quality

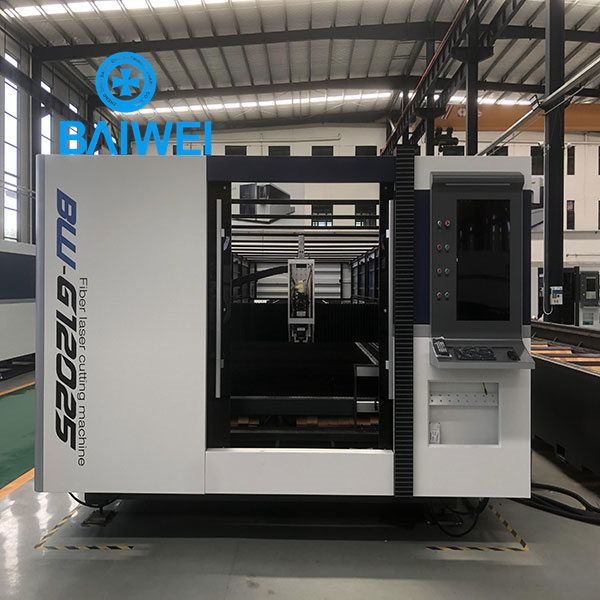

Model: BW-G6025

Cutting range: 6000x2500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 120m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

Contact US

Get Price

Share:

Content

itness equipment industry

The diversity of fitness equipment also puts forward high requirements for processing. Various specifications and shapes make traditional processing complicated and inefficient. Laser cutting has high processing flexibility, and can carry out customized flexible processing for different pipes and plates, and the finished product after processing is smooth, burr-free, and does not require secondary processing, and the quality and efficiency are greatly improved compared to traditional processes.

Advertising metal word industry

Advertising traditional processing equipment generally uses materials such as processing advertising fonts. Due to the unsatisfactory processing accuracy and cutting surface, the probability of rework is quite large. The high-precision laser cutting technology does not require secondary rework, which greatly improves work efficiency and saves enterprise costs.

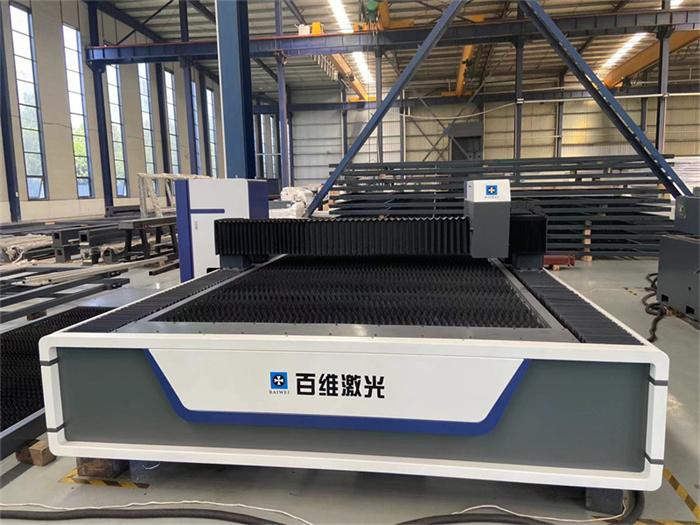

Sheet metal processing industry

With the rapid development of sheet metal processing technology, traditional sheet metal cutting equipment can no longer meet the requirements of current technology and cutting shape. Laser cutting has gradually replaced traditional equipment with the advantages of high flexibility and fast cutting speed. Fiber laser cutting machine Widespread application in sheet metal processing is an inevitable trend.

Medical equipment industry

Medical devices are closely related to human life safety and play an important role in human life. High-precision fiber laser cutting machine protects human life safety. Fiber laser cutting machine can process cutting parts with small wedge angle and high aspect ratio. Compared with conventional laser processing, the slit width, slit wedge angle and recast layer thickness are significantly reduced. Laser cutting can make the workpiece surface smooth and burr-free, and no subsequent processing is required, saving time and labor costs. Due to its flexibility,

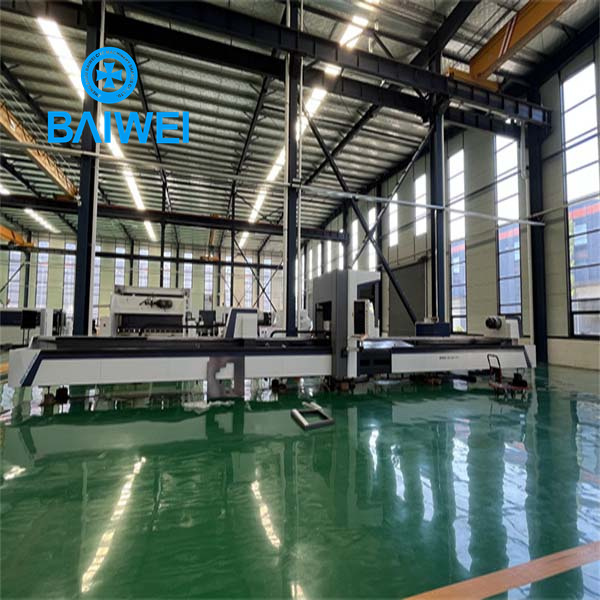

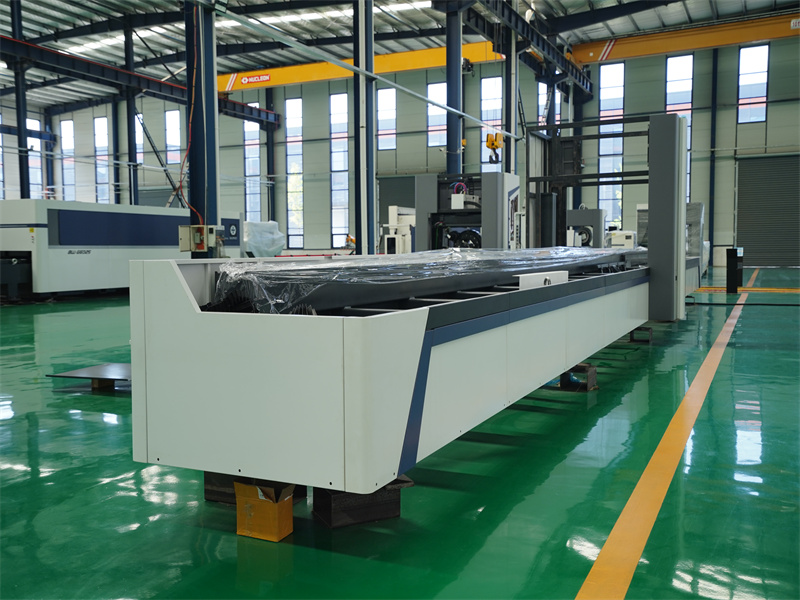

Used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, gift crafts, tool processing, decoration, advertising, metal foreign trade processing all kinds of manufacturing Processing Industry. Mainly used for cutting low carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling sheet, aluminum zinc sheet, copper and various metal materials.

Fiber laser cutting machine can cut a wide range of materials, including stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, galvanized sheet, pickling sheet, titanium and other metal sheets. Application industries include sheet metal processing, kitchenware manufacturing, chassis electrical cabinets, auto parts manufacturing, and metal sheet processing industries such as electric saw blades.

Suitable for cutting a variety of materials, generally acrylic, leather, fabric, metal, etc. are more suitable. According to the size of the power format, it can be used in different industries. The cutting of fabrics can be used in clothing, carpets, industrial fabrics, etc., and the acrylic cutting machine can be used in the production of acrylic handicrafts. The cutting can replace the original cutting to do all kinds of metal products.

The ultra-high power laser cutting machine can carry a maximum laser power of 35000W, so it is an ideal choice when cutting some thicker plates. For example, in the manufacture of large-scale machinery and equipment such as agricultural machinery, textile machinery, food processing machinery and construction machinery, ultra-high-power laser cutting machines are usually used for processing.

Inquiry

More Fiber Laser Cutting Machine