Compared with traditional processing technology

Parameter

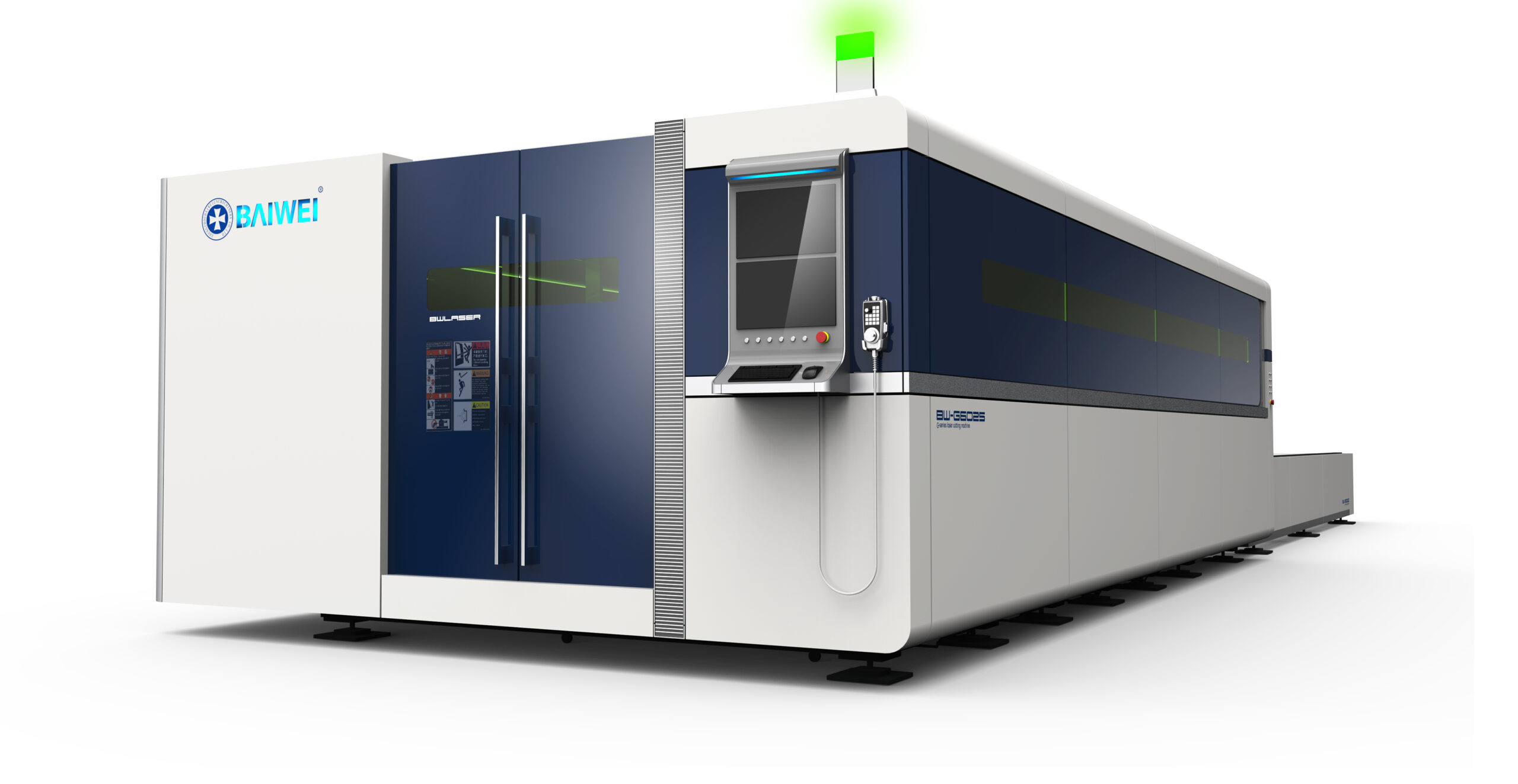

Models BW-G3015 BW-G4015 BW-G4020 BW-G6015 BW-G6020 Optional

Cutting range 3000x1500mm 4000x1500mm 4000x2000mm 6000x1500mm 6000x2000mm Optional

Laser power 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw

Max moving speed 100m/min

Max cutting speed 35-80m/min

Positioning accuracy 0.03mm

Repositioning accuracy 0.02mm

Min line width 0.1mm

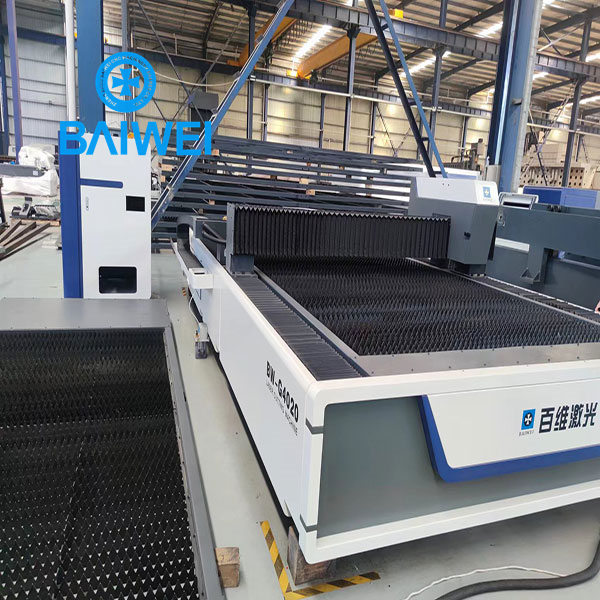

laser cutting machine has obvious advantages. Laser cutting combines a high concentration of energy and pressure, making it possible to cut smaller and narrower areas of material with significantly less heat and material waste. Laser cutting has high precision and can process complex geometric shapes with smooth edges and more obvious cutting effects.

The biggest advantage of using laser cutting technology is to reduce the mechanical stress on sheet metal parts during cutting. Not only does the laser eliminate the impact stress that can adversely affect the sheet during cutting, but the heating zone is also small. With this advantage, the remaining workpiece is hardly affected by heat, thus maintaining the properties of the material being processed.