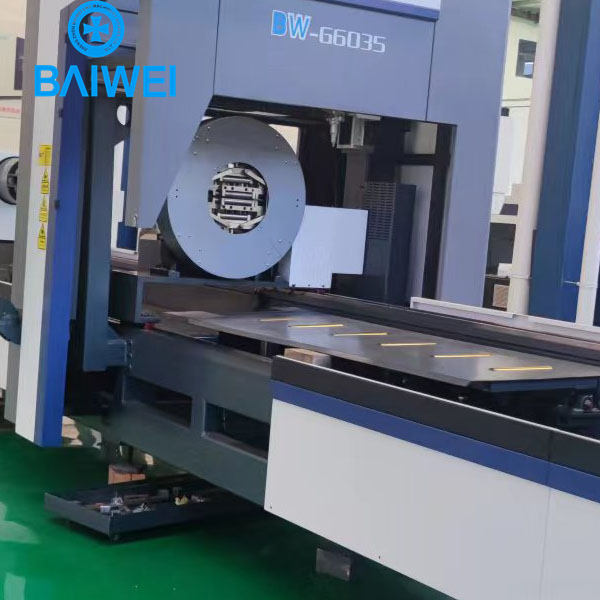

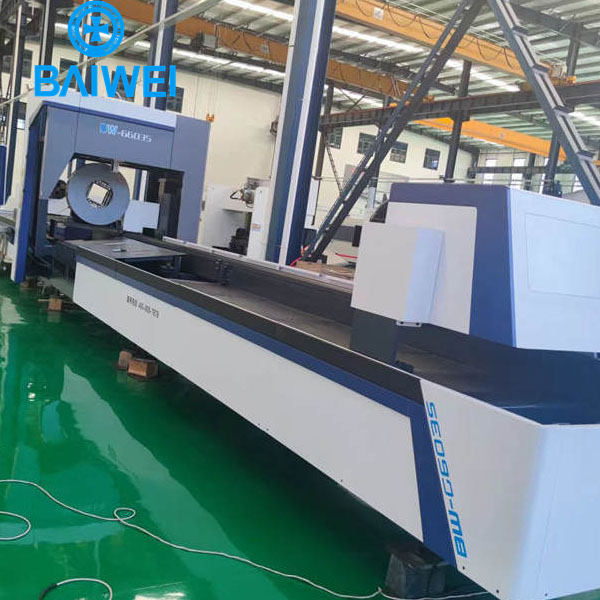

CO2 fiber laser cutting machine for stainless pipe

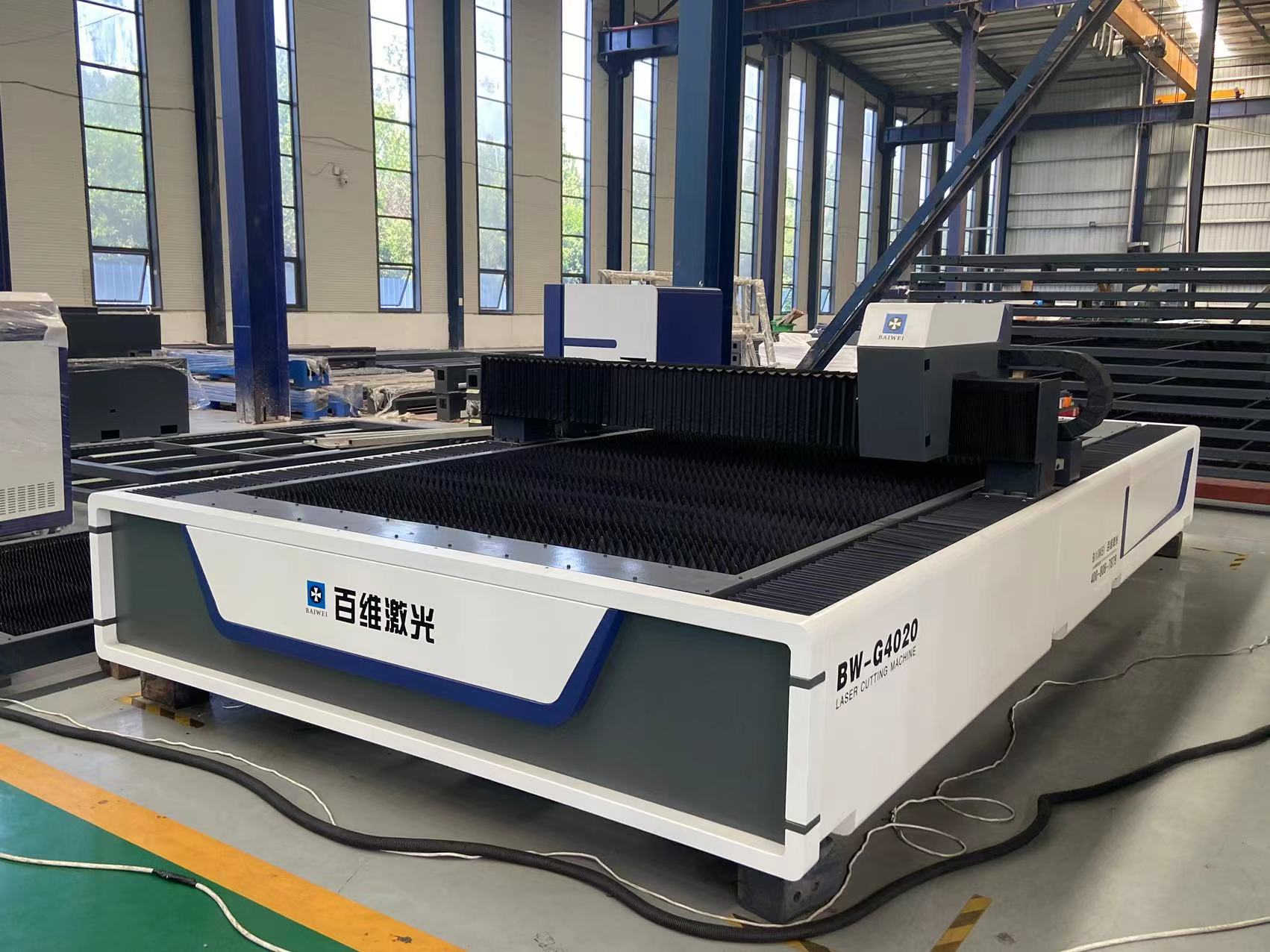

The energy density of laser processing is large, the action time is short, the heat affected zone is small, the thermal deformation is small, and the thermal stress is small. In addition, the laser is non-mechanical contact processing, which has no mechanical stress on the workpiece, which is suitable for precision machining. Output Power:

2kw/3kw/4kw/6kw/8kw/12kw (Optional)

Model:

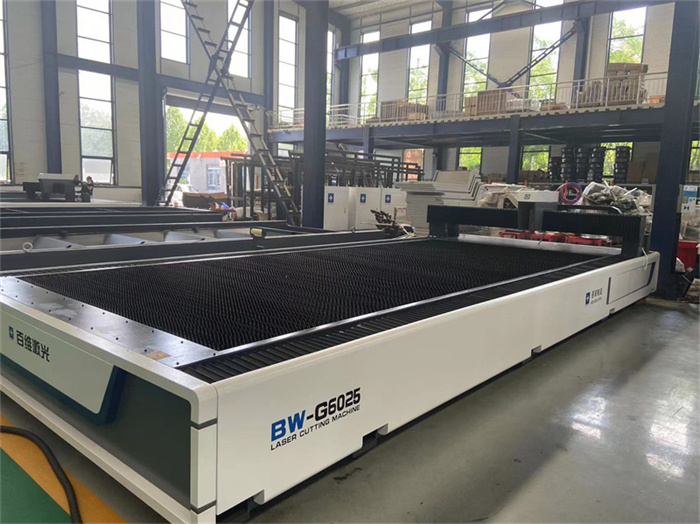

BW-G6000/BW-G9000/BW-G12000 (Optional)

Tube Diameter:

160mm/240mm/280mm/350mm/450mm/500mm (Optional)

L3 series all have two chucks (the rear chuck has 6 meters of moving space, and the front chuck is a fixed chuck that cannot be moved). Roller. The main bed is equipped with 2 sets of high-speed pneumatic supporting rollers as standard; the chuck speed is 120 rpm, the minimum working range of the 160 chuck is 20 mm, the minimum working range of the 240/280 chuck is 25 mm, and the minimum working range of the 350 chuck is 30 mm. Dimensional parallel automatic feeding machine, chain conveying, platform support artificially assisted automatic conveying,