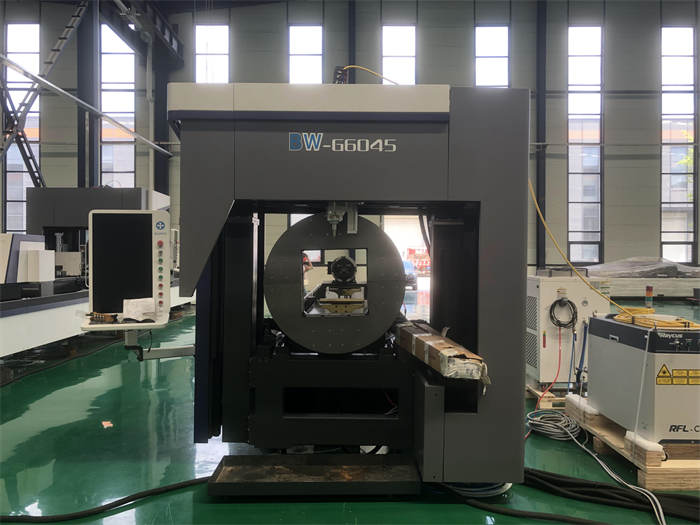

CNC stainless closed type fiber laser cutting machine for sheet metal

The laser processing of the enclosed fiber laser cutting machine is a non-contact flexible processing, which is not affected by the shape of the workpiece, and can process any graphics. The closed fiber laser cutting machine can completely avoid the slump formed when the material is punched and sheared, and the cutting seam generally does not require secondary processing.

Laser Source:IPG/Raycus/Nlight

Laser Power:6kw/8kw/10kw/12kw/15kw/20kw (Optional)

Processing Surface:6000*2500mm/6000*2000mm/4000*2000mm (Optional)

Position Accuracy X, Y and Z Axle:¡À0.03MM

Cutting Thickness:Carbon Steel 0.5MM-30MM, Stainless Steel 0.5MM-16MM

Why is fiber laser cutting machine more and more popular?

The short answer is that you can focus the fiber laser wavelength to a tighter spot size, and get higher energy density. This allows for faster cutting for the same laser power, at least in materials thinner than 3 mm thick, than the same power CO2 laser would be able to do. They also have less maintenance, since there aren’t mirrors to routinely realign, and they have higher wall plug efficiency, so they cost less in electricity in the long run. For many equipment purchasers, these long term effects mean they will make more money laser cutting, and can mostly ignore the benefits a CO2 laser has on thick material, since it is only marginally more expensive to just purchase a higher power fiber laser.