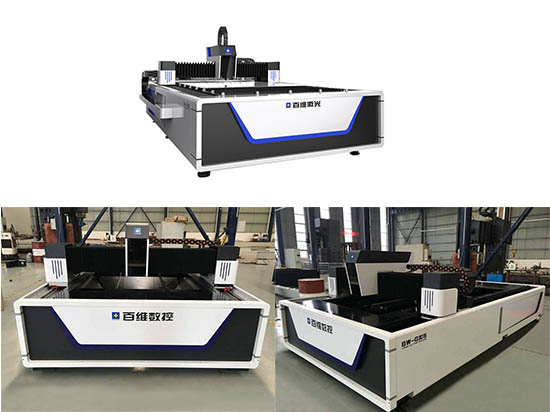

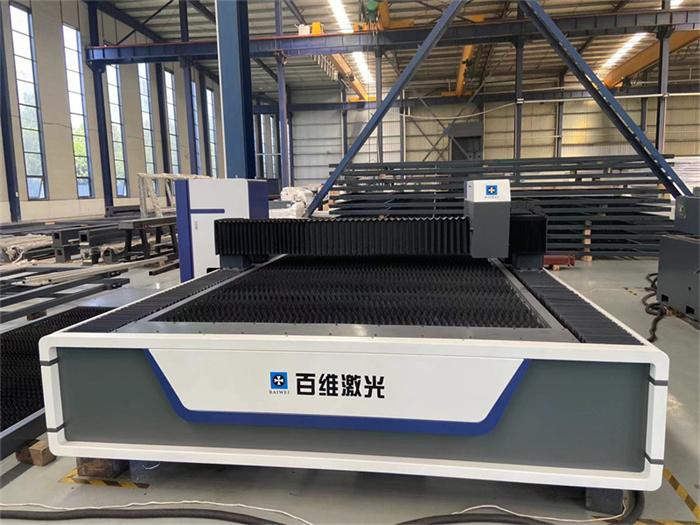

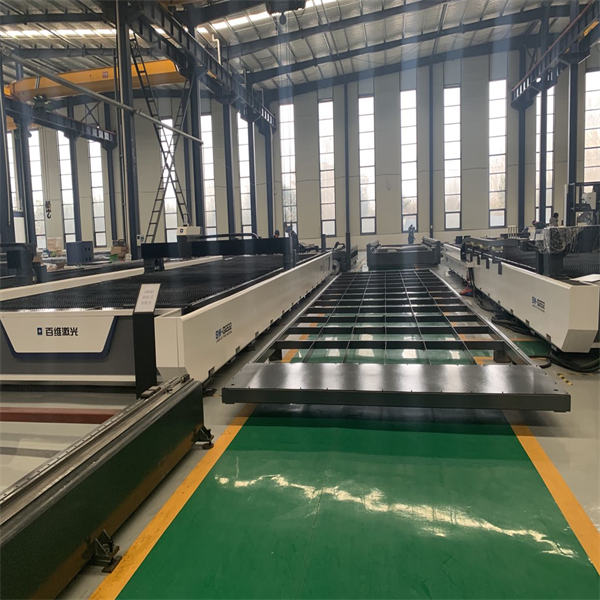

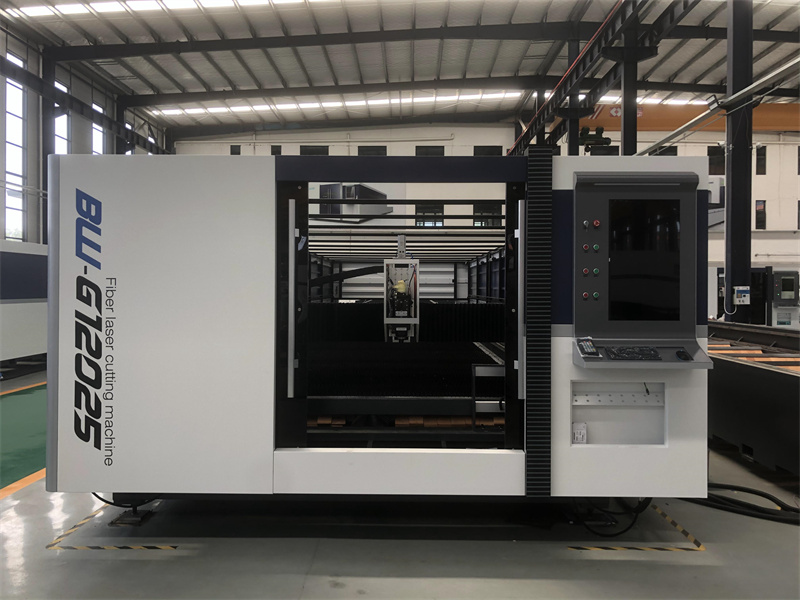

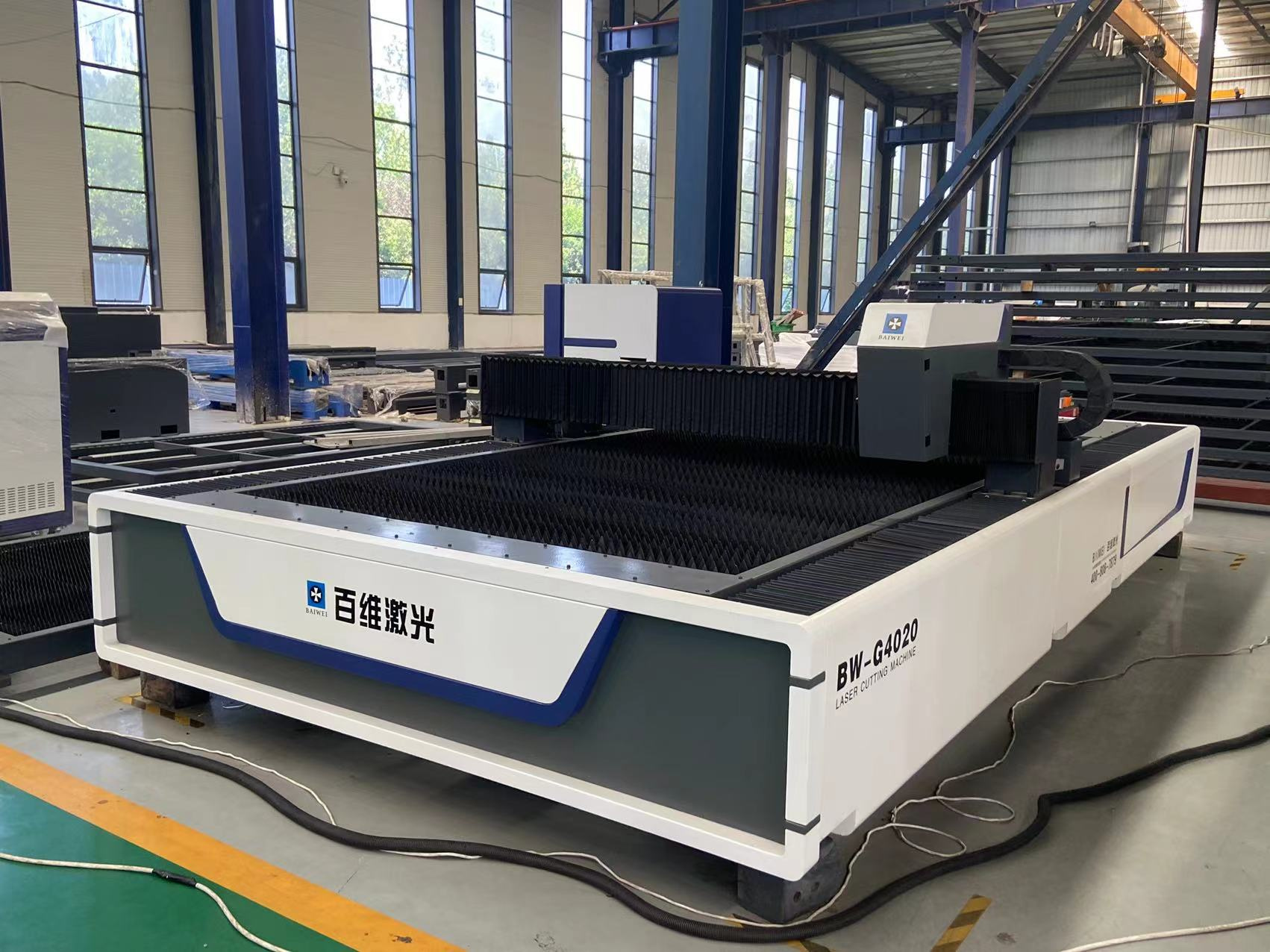

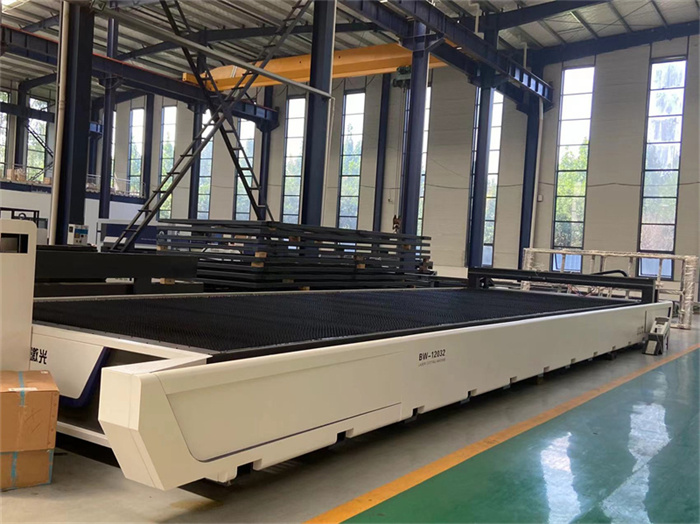

CNC Laser Cutting Equipment Large Format Fully Automatic Baiwei Laser Single Head Double Head Laser Cutting Machine

Model: BW-G6025

Cutting range: 6000x2500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 120m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

Advantages of laser cutting machine:

1. The slit is narrow, the precision is high, and the roughness of the slit is good. After cutting, there is no need to reprocess the next process.

2. The laser processing system itself is a computer system, which is easy to organize and modify, and is suitable for personalized processing. Especially for sheet metal parts with complex shapes and complex shapes, the batches are large and small, and the product life cycle is not long. In terms of technology, economic cost and time, the manufacture of molds is not cost-effective, while laser cutting has unique advantages.

3. Laser processing has the characteristics of high energy density, short action time, small heat affected area, small thermal deformation, and small thermal stress. In addition, laser processing is a non-mechanical contact processing, which has no mechanical stress on the workpiece and is suitable for precision processing.

4. The high energy density of the laser is enough to melt any metal, especially suitable for some difficult-to-process materials with high hardness, high brittleness and high melting point.

5. Low processing cost. The one-time investment in equipment is expensive, but continuous large-scale machining ultimately reduces the machining cost per part.

6. Laser non-contact processing, small inertia, high processing speed. Using CNC system CAD/CAM software programming, time-saving and convenient, high overall efficiency.

7. The laser has a high degree of automation, can be fully enclosed, has no pollution, and has low noise, which greatly improves the working environment of the operator.