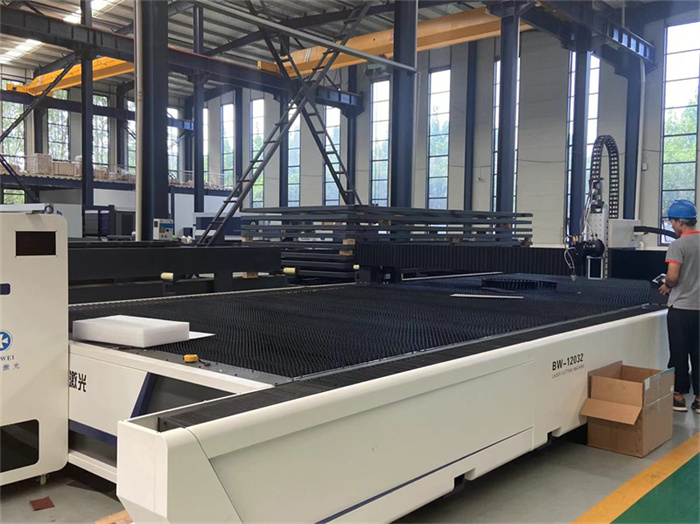

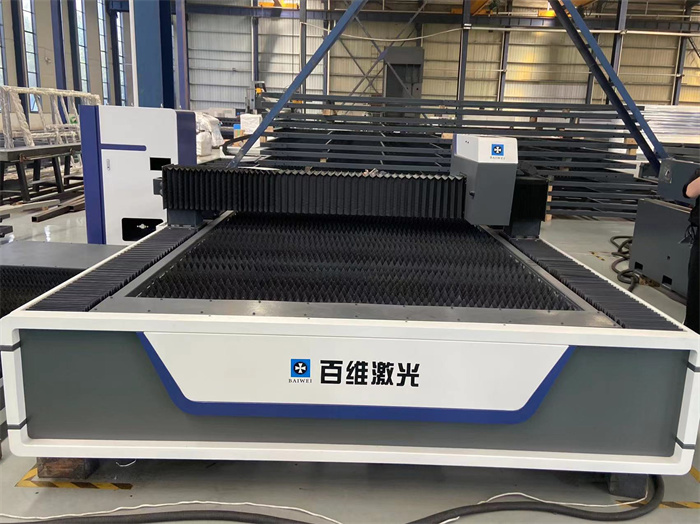

Home » Fiber Laser Cutting Machine » Carbon steel stainless steel sheet metal CNC fiber laser cutting machine 3000W cutting 16mm

Carbon steel stainless steel sheet metal CNC fiber laser cutting machine 3000W cutting 16mm

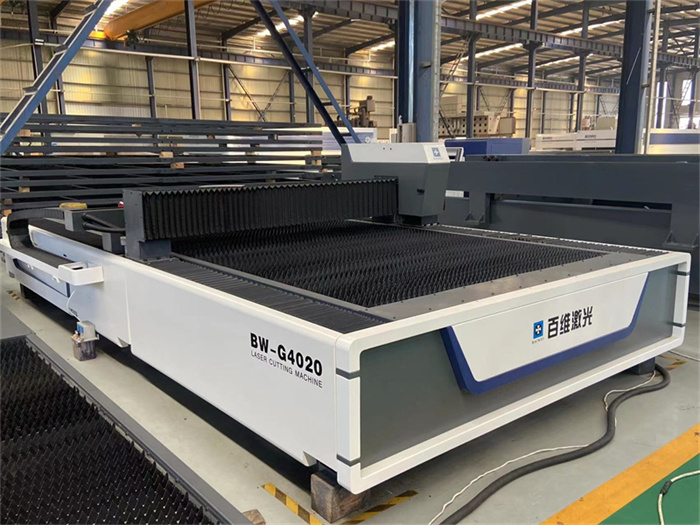

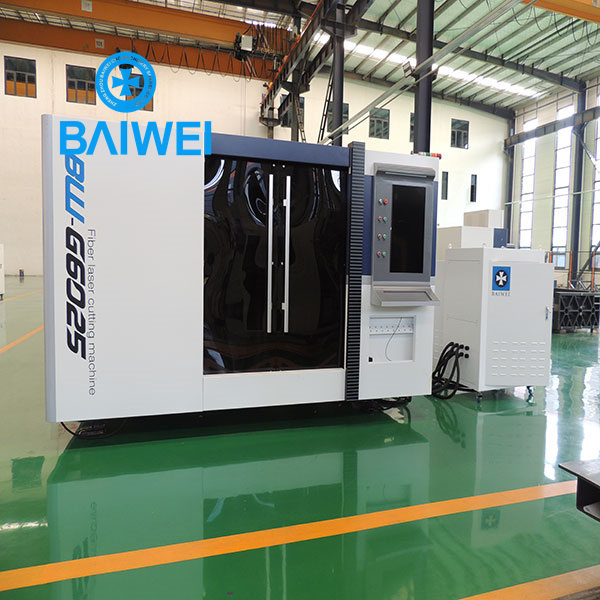

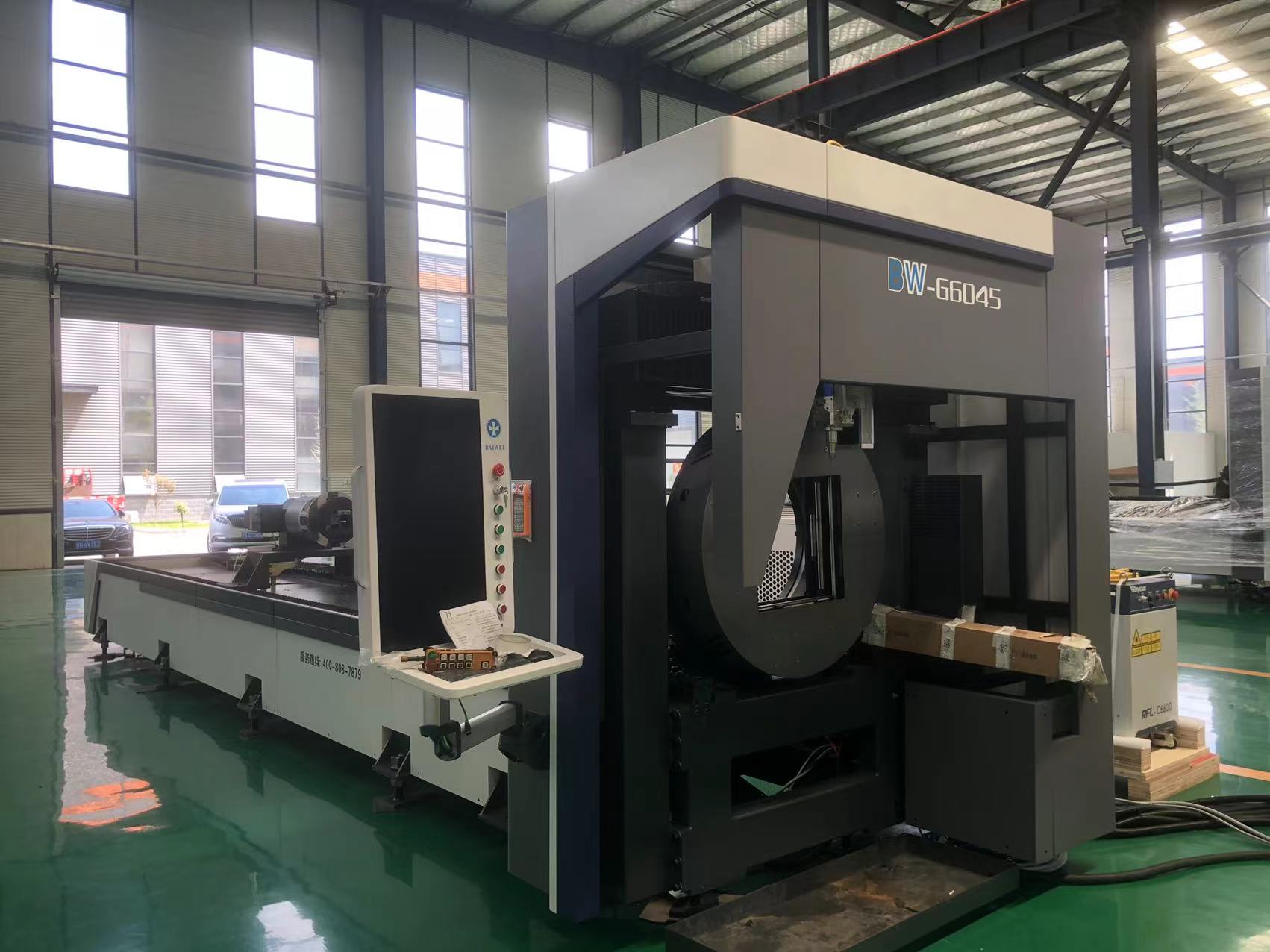

Model: BW-G6025

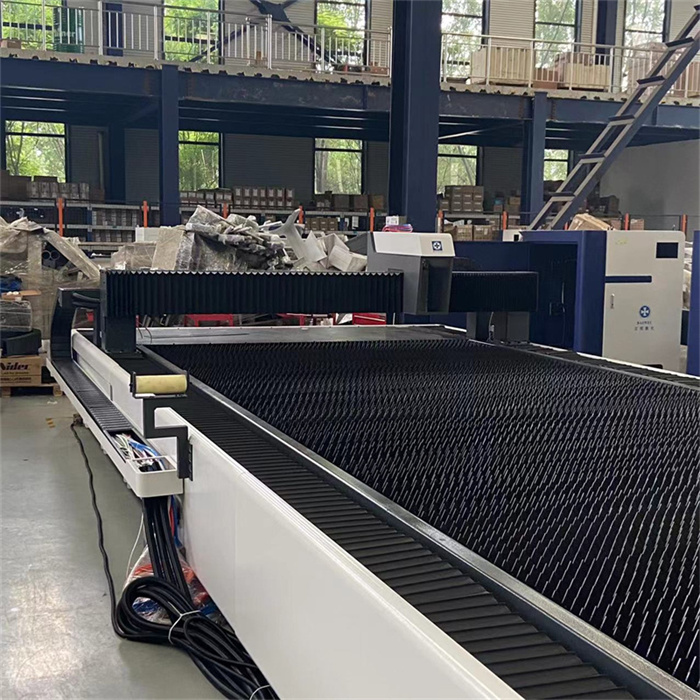

Cutting range: 6000x2500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 120m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

Contact US

Get Price

Share:

Content

How Does Laser Cutting Work?Before diving into laser cutting advantages and disadvantages, it is essential to understand how it works. The way how laser cutting machines work is similar to CNC machines work, but it uses a high-power laser. The laser will guide the material or beam by directing itself through CNC and optics. The device will use the CNC, or G-code provided, to cut into the material and control the motion.

Melting, vaporizing, and burning the material will occur after focusing the laser beam. Also, you can acquire a finished edge surface of high quality when you blow the material with a jet of gas. The creation of a laser beam occurs in a closed container by stimulating lasing materials through lamps or electrical discharge.

The amplification of the lasing materials then takes place after reflecting internally through a partial mirror. The phenomenon continues until enough energy is built up in the form of a stream of coherent monochromatic light to allow for its escape. The intensity of the light increases after using fiber optics or mirrors to focus on the work area.

Low Cost and More AffordableThe economic edge laser cutting has over other CNC machines of the same caliber is one of the advantages of laser technology. There is no need to build a custom tool with the laser cutting technology. You do not also need to modify the device for any project since no extra cutting tools are needed.

Also, there is no wearing out of the surface since there is no physical contact. The cost of maintenance is less than other machining technologies since the laser cutter’s mechanical parts are not much. The cost of operating the machine is also lesser compared to traditional tools for manufacturing.

Inquiry

More Fiber Laser Cutting Machine