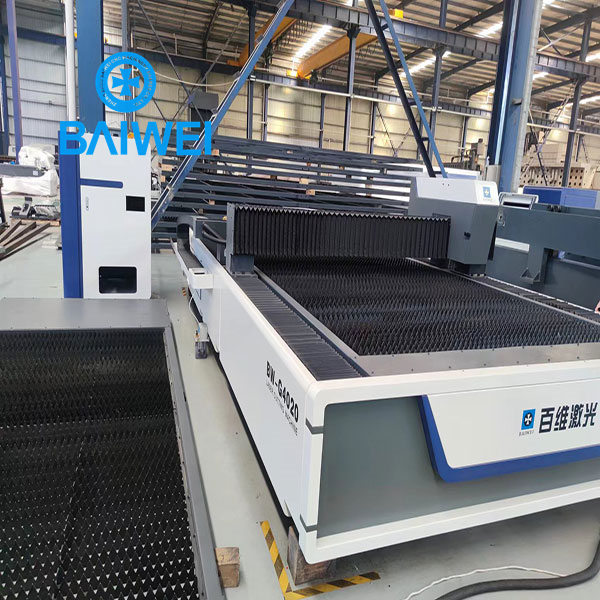

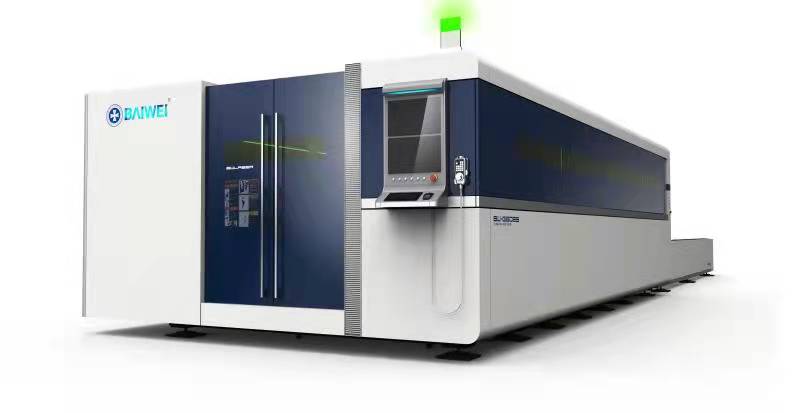

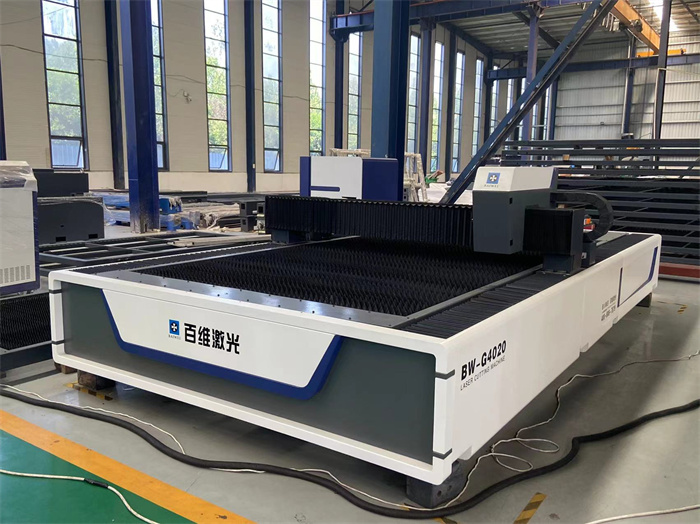

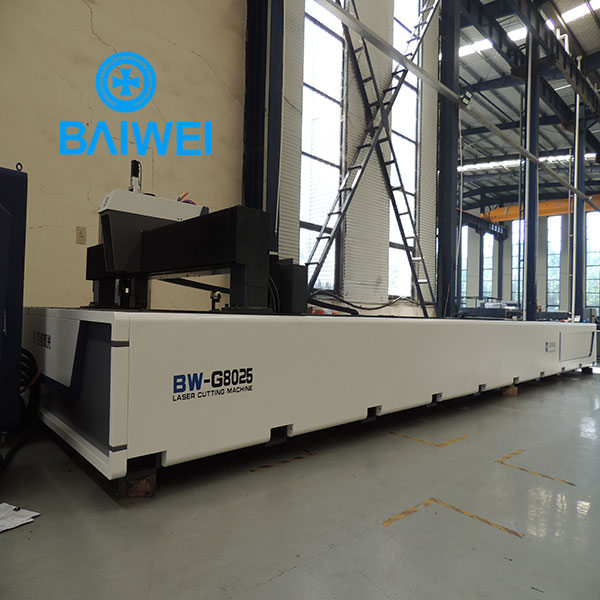

Bull closed type fiber laser cutting machine for aluminum plate

The enclosed fiber laser cutting machine does not damage the workpiece. The laser cutting head will not come into contact with the surface of the material, ensuring that the workpiece will not be scratched.

Laser Source:IPG/Raycus/Nlight

Laser Power:6kw/8kw/10kw/12kw/15kw/20kw (Optional)

Processing Surface:6000*2500mm/6000*2000mm/4000*2000mm (Optional)

Position Accuracy X, Y and Z Axle:¡À0.03MM

Cutting Thickness:Carbon Steel 0.5MM-30MM, Stainless Steel 0.5MM-16MM

What are the various types of laser cutting machine?

Laser cutting technology is constantly developing, and new lasers appear on the market for Laser Cutting Perth, and other Australian cities. Below is a quick overview of 3 most popular laser models for working with different types of metals. Each of them has its advantages and disadvantages:

Solid State YAG Laser

Due to its high peak power and large spot size, the YAG laser is well suited for microwelding. In solid-state YAG lasers, the active medium is a rod of yttrium aluminum garnet, and gas-discharge lamps or laser diodes carry out pumping. However, the crystal rod deforms over time under the influence of pumping diodes. It leads to a significant deterioration in the quality of the beam. Sometimes it leads up to the failure of the entire machine. The crystal has a short lifespan, and expensive pump diodes also require periodic replacement.[1]

Disc laser

High cooling efficiency is achieved by using a disc shape with a large surface area instead of a rod. The thin laser disk is connected to a conductive-type heat dissipation system. The design features of the disk laser make it possible to generate high-intensity radiation of very high power with an almost complete absence of parasitic optical effects. However, most standard technological operations do not require as much radiation power as an expensive disk laser can generate.[2]

Fiber laser

An optical fiber doped with ions of rare-earth elements acts as an active medium in these lasers, and pumping is carried out using laser diodes. The small spot size found in fiber lasers ensures precision when cutting metal. Besides, the highly efficient generation process allows for air cooling, simplifies the unit’s operation, and reduces its overall dimensions. Typically, the design of fiber lasers is a separate module with a fiber optic cable outlet, which significantly simplifies the integration of the laser source into a CNC machine.