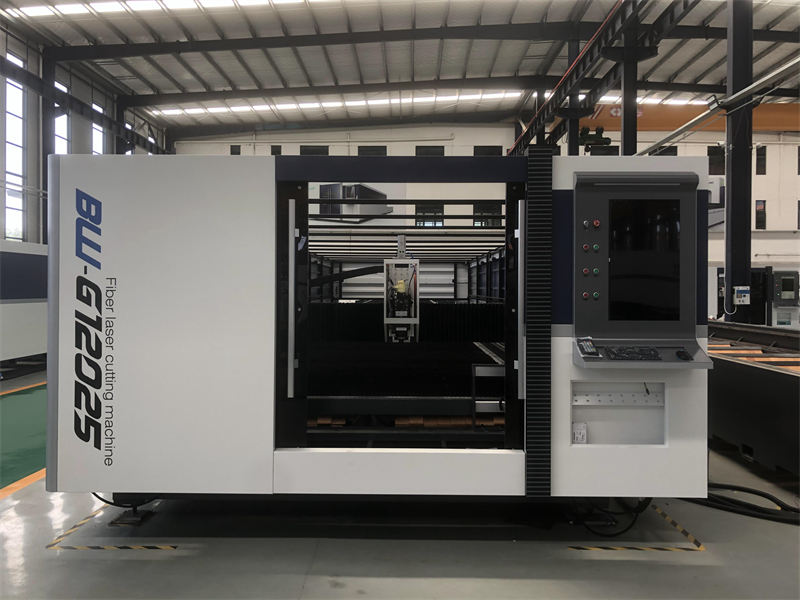

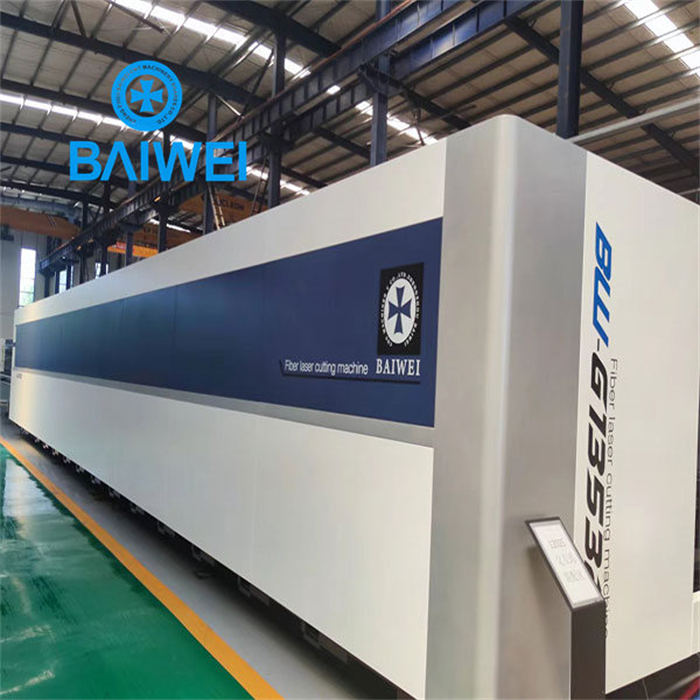

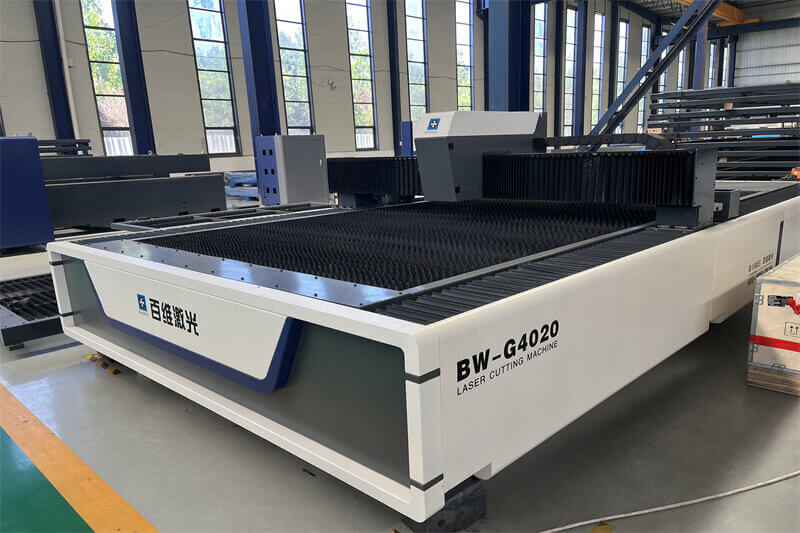

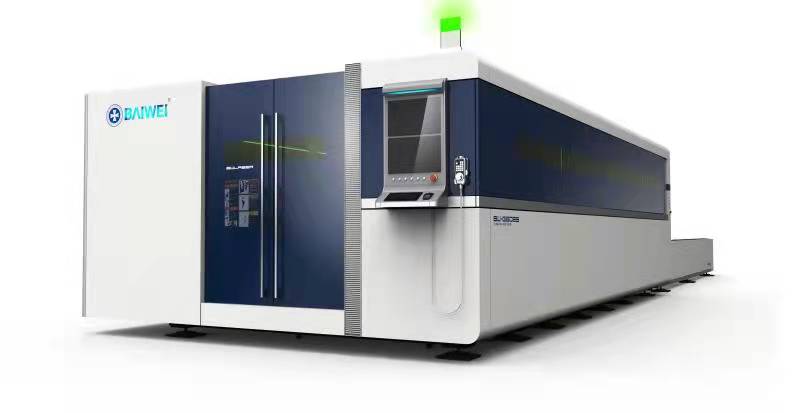

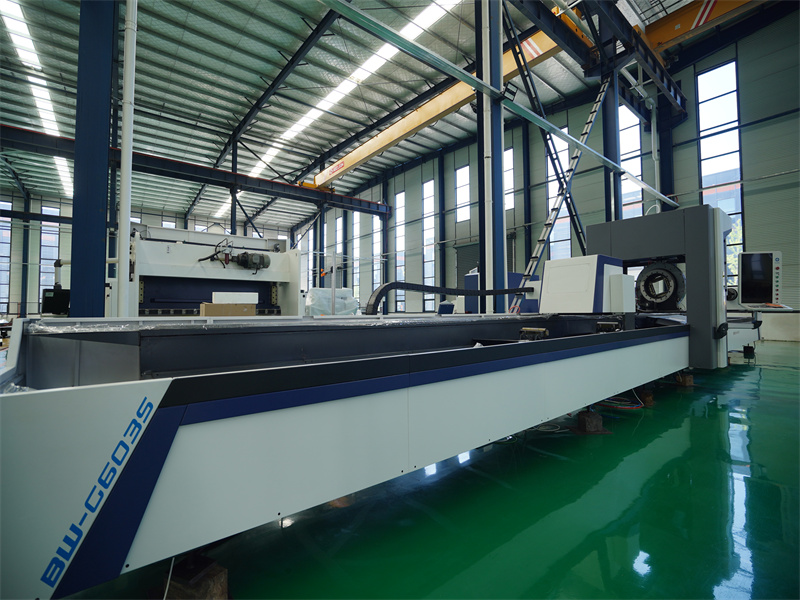

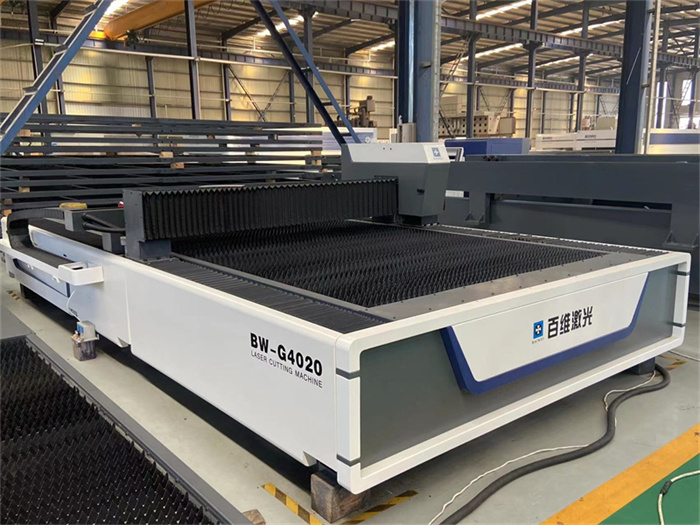

Bulk direct factory closed fiber laser cutting machine

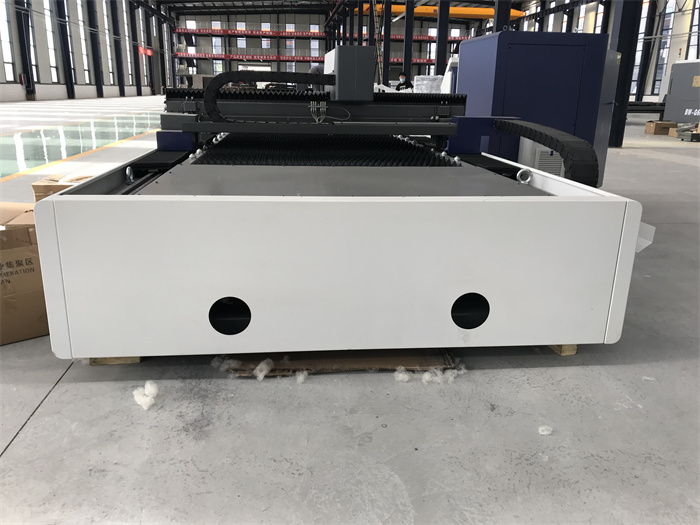

The enclosed fiber laser cutting machine has excellent beam quality, smaller focusing spot, higher work efficiency and better processing quality. The enclosed fiber laser cutting machine has a very high cutting speed, which is twice that of the same power CO2 laser cutting machine.

Laser Power:2kw/3kw/4kw/6kw/8kw

Laser Source:IPG/Raycus/Nlight

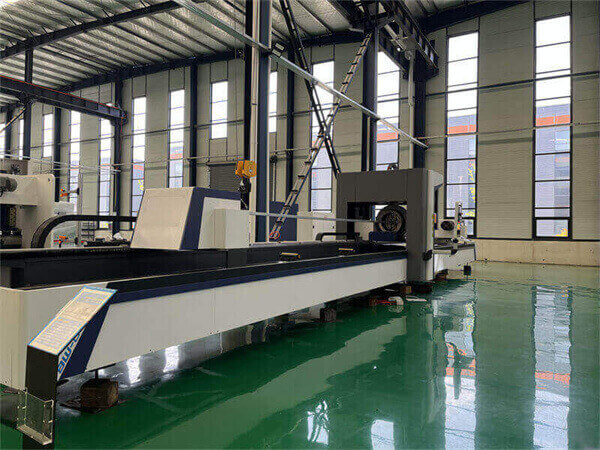

Processing Surface (L*W):3000*1500mm/4000*2000mm/6000*2000mm (Optional)

Position Accuracy X, Y and Z Axle:±0.03mm

Cutting Thickness:Carbon Steel 0.5MM-30MM, Stainless Steel 0.5MM-16MM

For hobbyist tabletop lasers, many are diode lasers in the 1–5 Watts range, with some higher end units using a sealed resonator CO2 laser.

For industry, a growing number of customers that use lasers to cut thin gauge mild steel, galvanized steel, stainless steel, or aluminum, are switching to fiber lasers due to the inherent simplicity of the system(it’s essentially a chiller unit, a big box full of LED lights to pump the laser, and a special fiber that does beam delivery as well as generation of the laser light, so less places for something to go wrong) , and the increased cutting speeds (more parts per hour= more money).

Now, for thicker plates the fiber laser actually cuts slower than a CO2 laser, and a smart industrial purchaser, who is shopping for a machine to cut thick plates, will note that while a CO2 laser has more parts to maintain, and may have more downtime for maintenance, they will pay out in the long run with faster times on these thick plates, and a lower initial cost. The dilemma lies in looking closely at the product mix being run on the machine.

Some large toll processors will simply buy higher powered fiber laser units to replace lower powered CO2 units to maintain the speed, and the simplicity, but the initial purchase cost is much higher.

But, as fiber lasers are still relatively new in terms of machine tool/ capital equipment years(I.e. equipment is purchased once for a 20–30 year life) , CO2 lasers are still most likely to be the most used lasers for cutting, and will stay this way for at least a few more years.