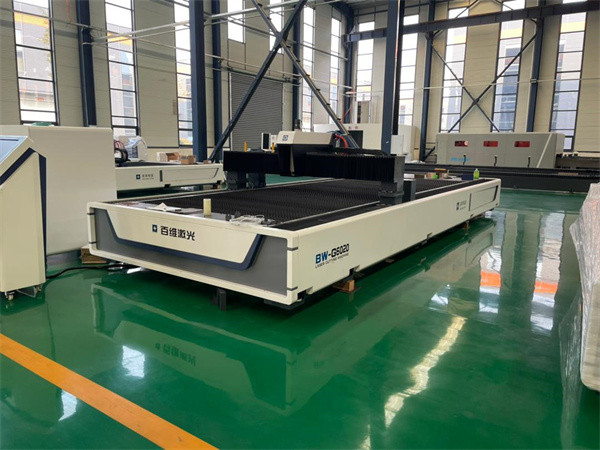

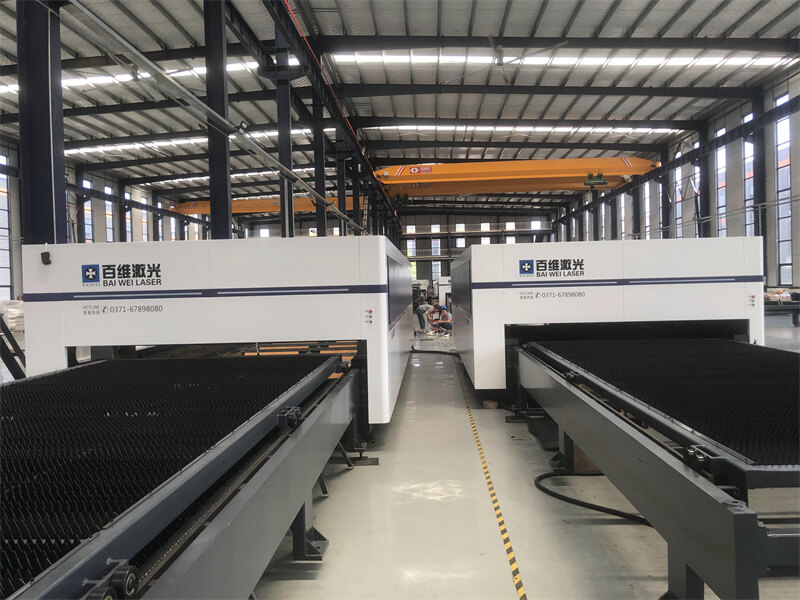

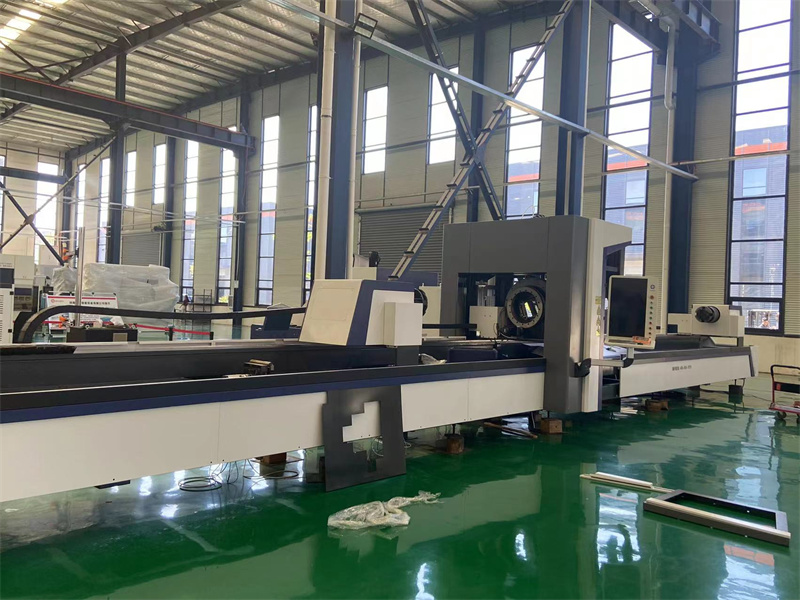

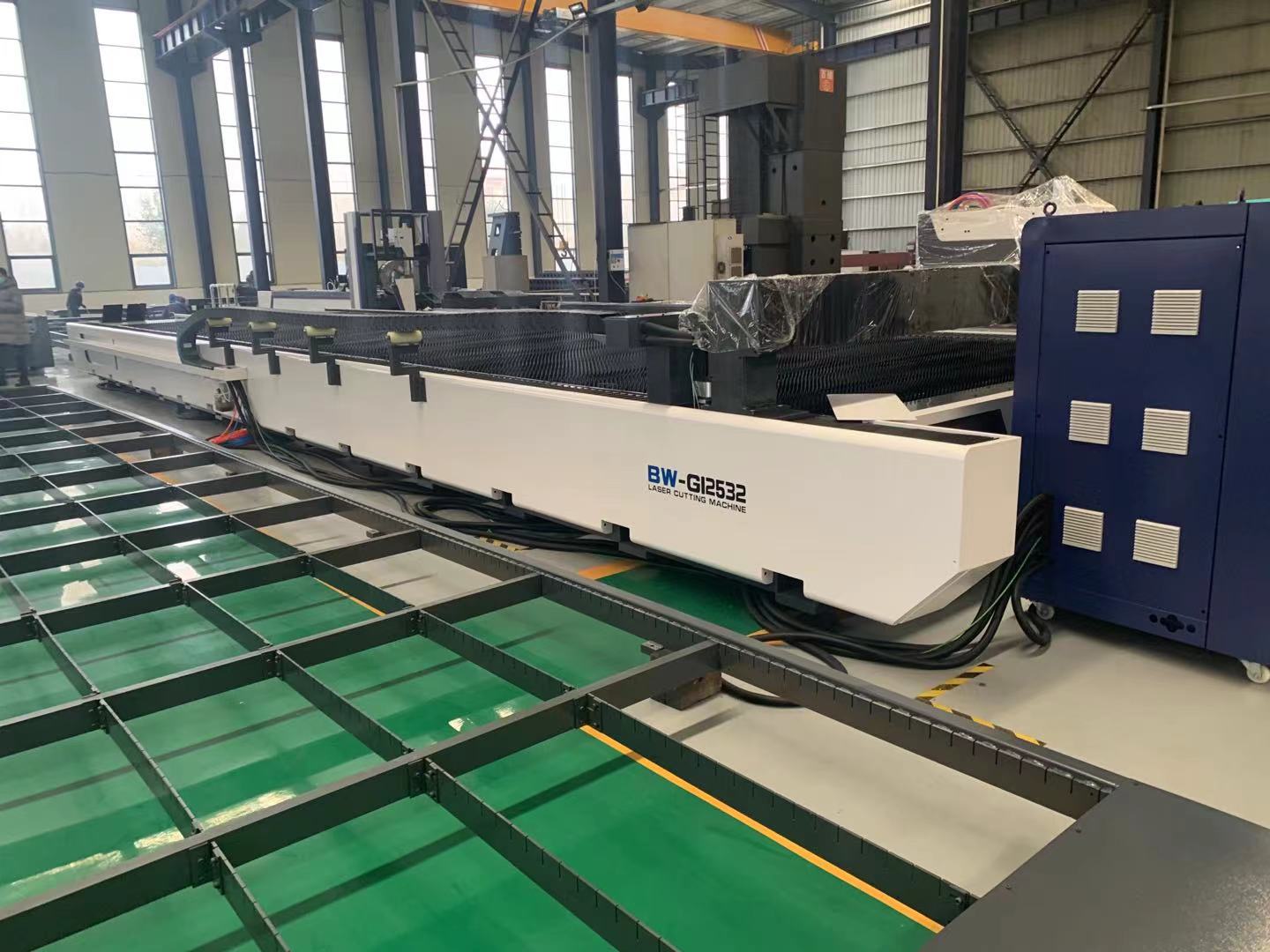

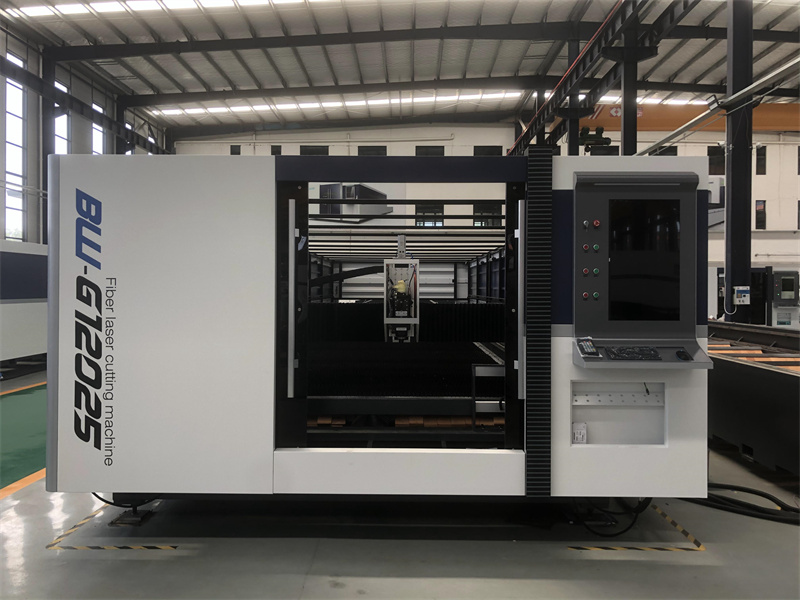

Best carbon steel closed type fiber laser cutting machine with factory Outlet

The closed type fiber laser cutting machine can effectively protect the safety of operators. Reinforcing ribs are set in the middle of the bed, and the closed type fiber laser cutting machine adopts a craft bed to improve the service life of the bed.

Laser Source:IPG/Raycus/Nlight

Laser Power:6kw/8kw/10kw/12kw/15kw/20kw (Optional)

Processing Surface:6000*2500mm/6000*2000mm/4000*2000mm (Optional)

Position Accuracy X, Y and Z Axle:¡À0.03MM

Cutting Thickness:Carbon Steel 0.5MM-30MM, Stainless Steel 0.5MM-16MM

What should we pay attention to when use a laser cutting machine?

The service life of a fiber laser cutting machine related to the maintenance and daily operation. If you could guarantee the normal condition of a fiber laser cutter, it could help you improve the working efficiency in a great level. The maintenance not only reflects in the daily operating, but also need to be noticed after the operation.

Before start the machine, you need to examine all the components whether they are in normal condition. Such as the water chiller, auxiliary gas and laser generator, if these components have some problem, it¡¯s harmful for the safety of workers.

During the operation, making sure that the machine is staying at a normal condition is very important. For example, you need to pay attention to the data of operation platform, and the cutting head should be carefully operated because it includes many precise parts, like nozzle, auto focus lens and so on. Further, you need to observe the situation of indicator light, so as to guarantee the safety of machine.