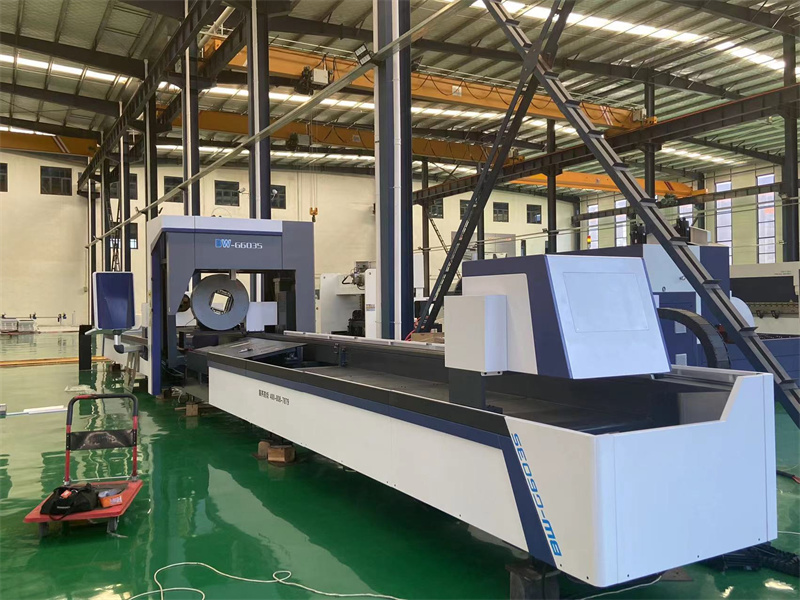

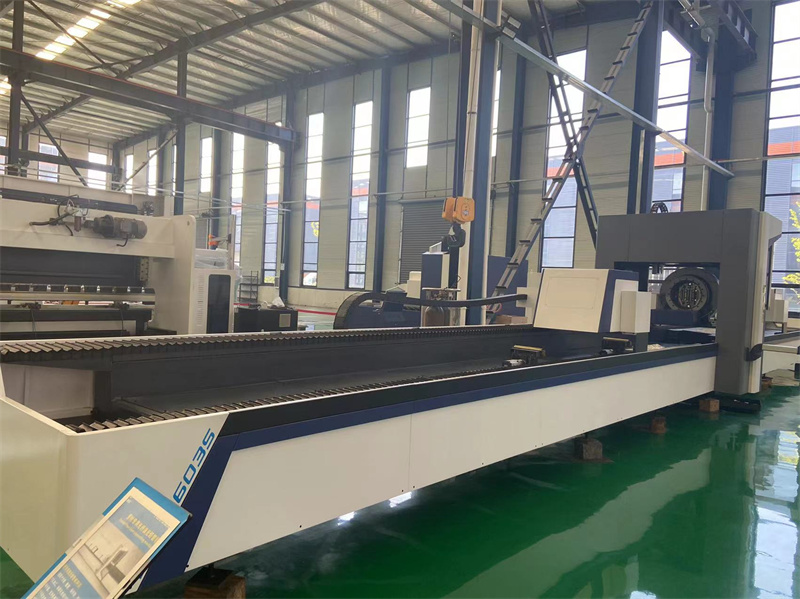

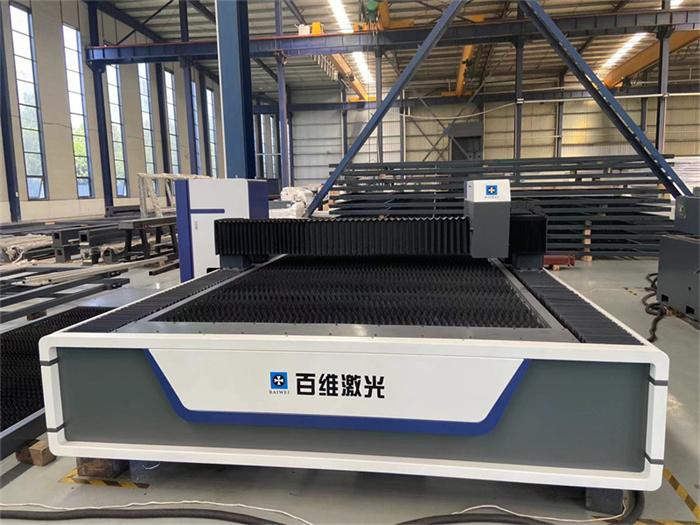

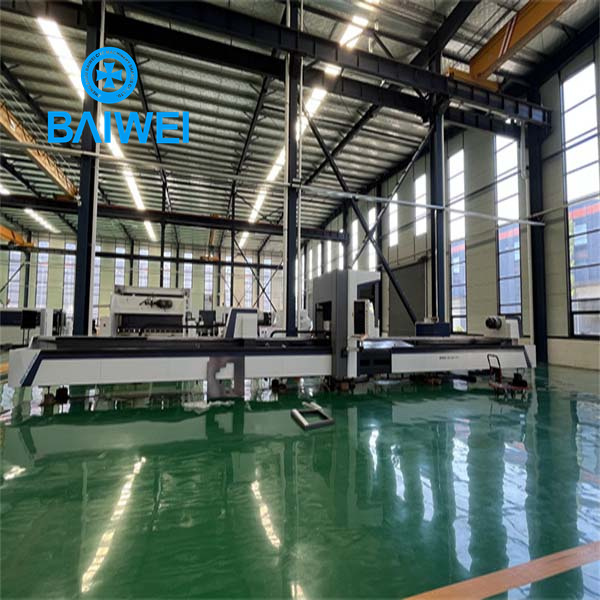

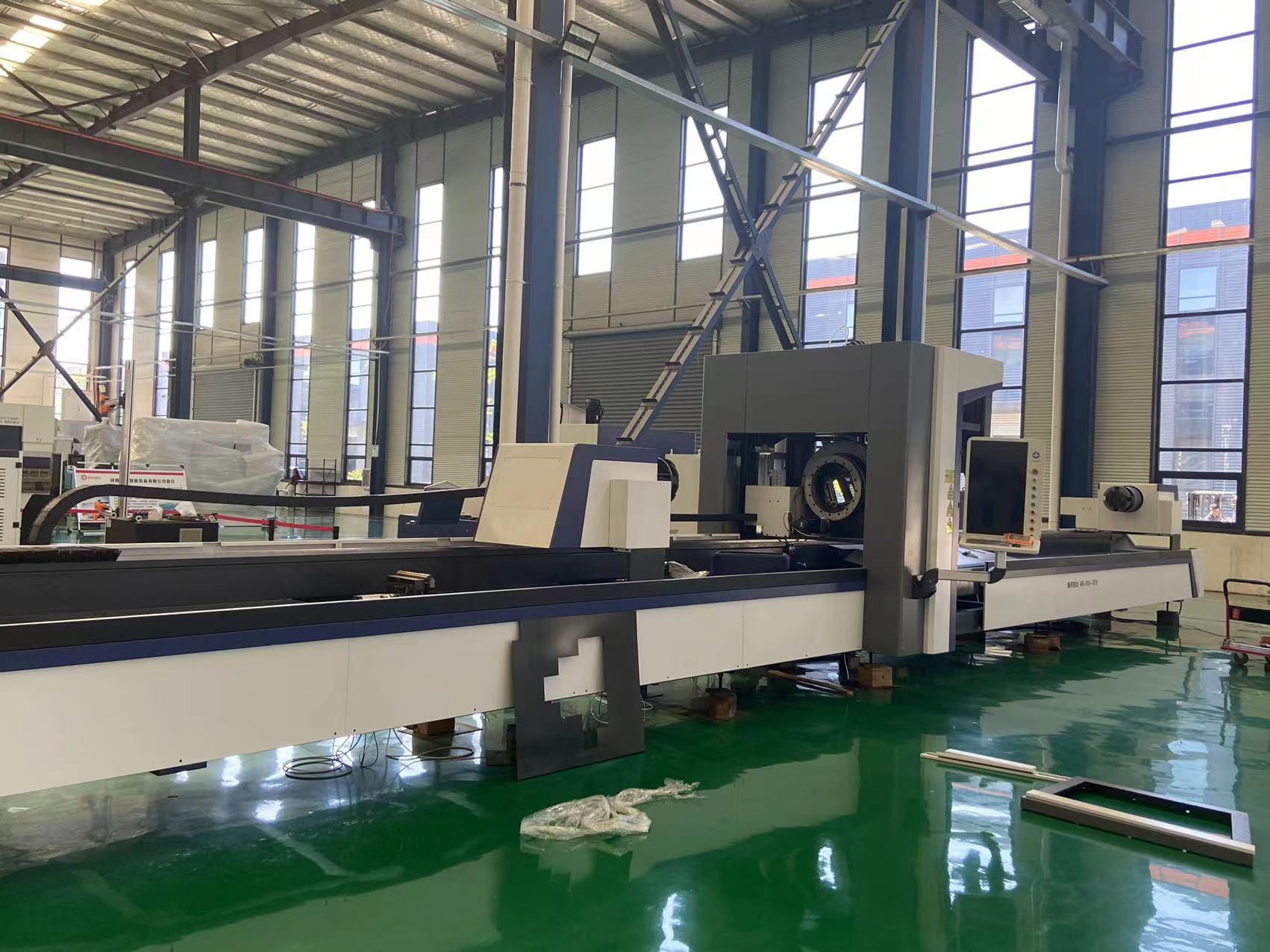

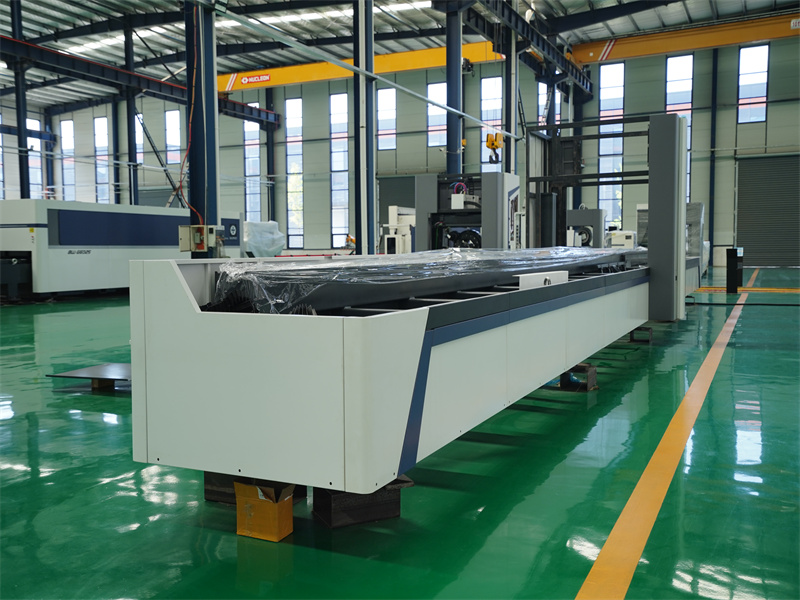

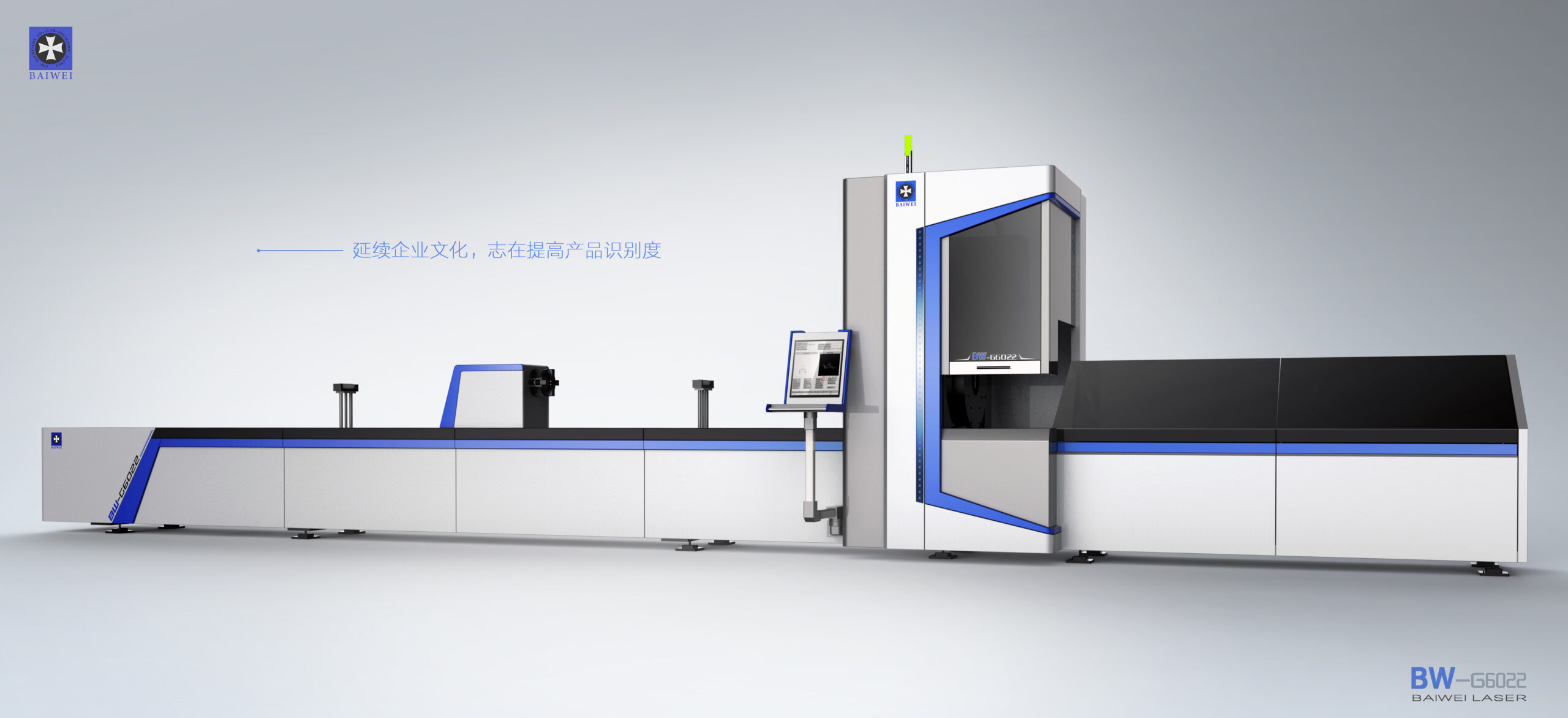

Best carbon steel closed type fiber laser cutting machine with direct factory

The closed type fiber laser cutting machine uses today’s most advanced German IPG fiber laser, with extremely high photoelectric conversion efficiency. The laser generation process does not require gas, and air-assisted cutting.

Laser Source:IPG/Raycus/Nlight

Laser Power:6kw/8kw/10kw/12kw/15kw/20kw (Optional)

Processing Surface:6000*2500mm/6000*2000mm/4000*2000mm (Optional)

Position Accuracy X, Y and Z Axle:¡À0.03MM

Cutting Thickness:Carbon Steel 0.5MM-30MM, Stainless Steel 0.5MM-16MM

How do we adjust the resonator in the CO2 CNC laser to minimize the deviation of the output light?

try tightening the small downward directing mirror in the little 45¡ã cutting head. If this mirror is loose in there, it will flop around every time the carriage changes direction and leave unequal edges on the sides. Your laser resonator should not be deviating enough to actually move the beam¡ the output power level is changing? or the desired position is changing? May be slack in cables. Clamp down make sure the laser tube is mounted secure in holder before adjusting the resonator mirrors. Start with output coupler and use a power meter directly connected, de-tune, re-tune one and then peak the other axis. Most dc/rf tubes I have seen are hard-sealed and you can¡¯t adjust the laser optics.