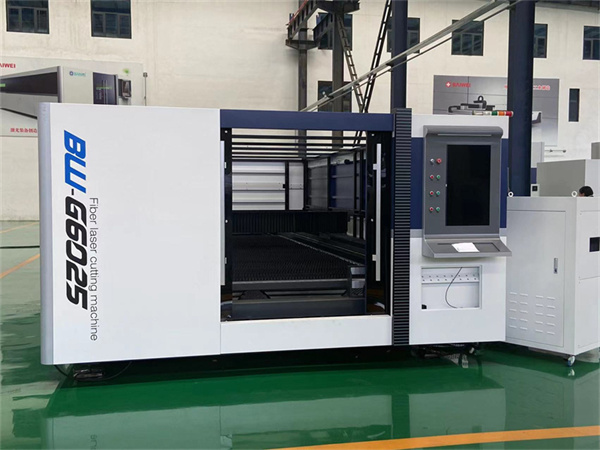

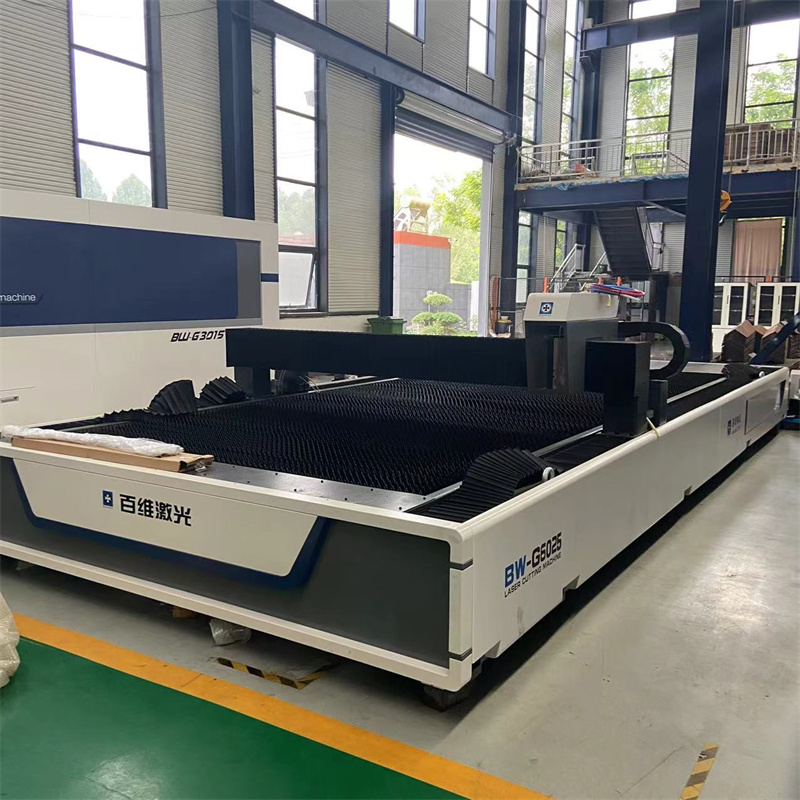

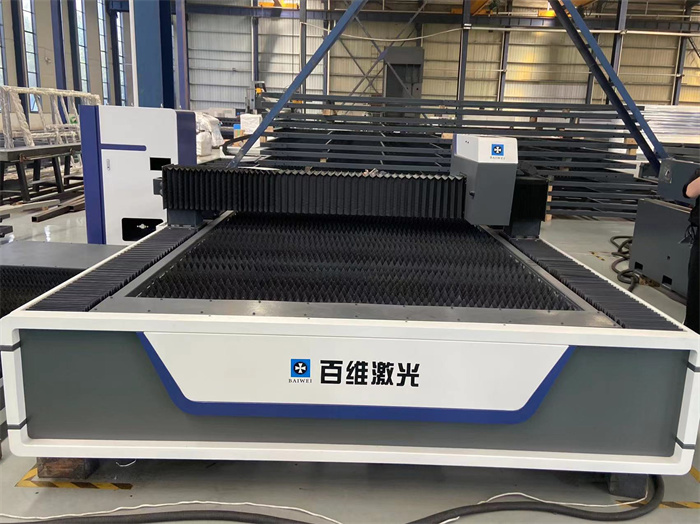

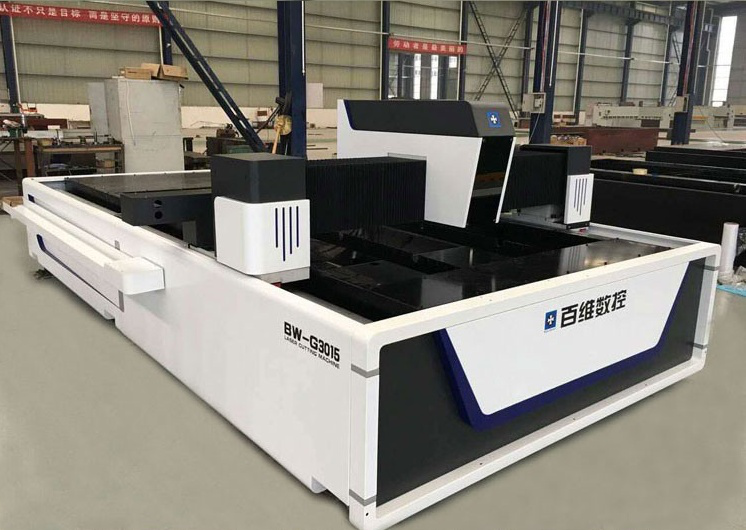

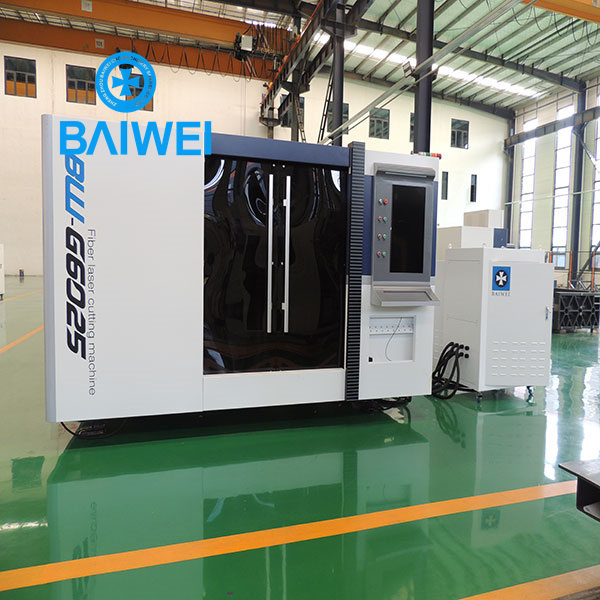

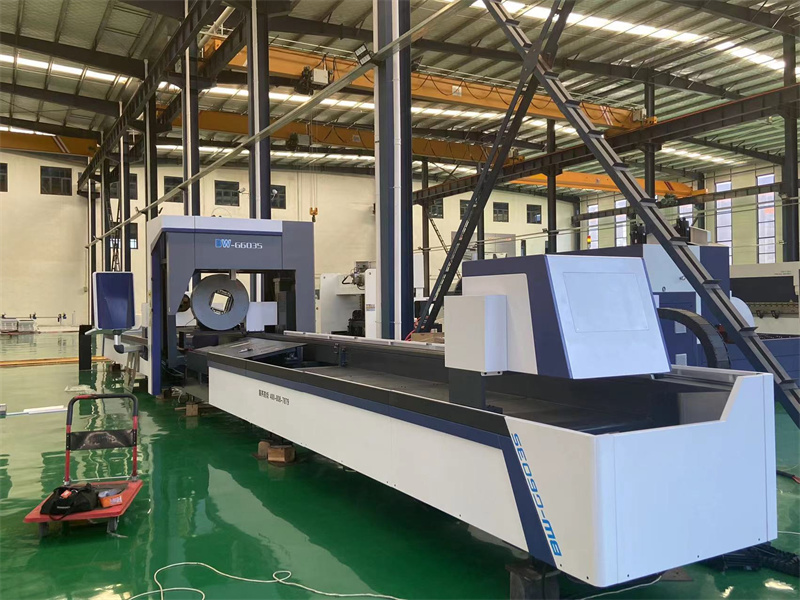

Baiwei laser cutting tube laser cutting machine – High Stability & High Speed

Parameter

Model BWQG6016-6000*160 professional tube laser cutting machine

Motor and Drive Panasonic/Fuji

Laser head Baiwei customized laser cutting head&Swiss Raytools auto focus laser cutting head&Precitec auto focus laser cutting head (Opitional)

Gear, rack APEX/YYC

Reducer Shimpo&Neugart

Tailing length 15mm-30mm Shortest tailing waste in this industry,we can also do 0 tailing without any waste

Cutting diameter ≤499mm

Cutting length 6000mm/9000mm/12000mm (Optional)

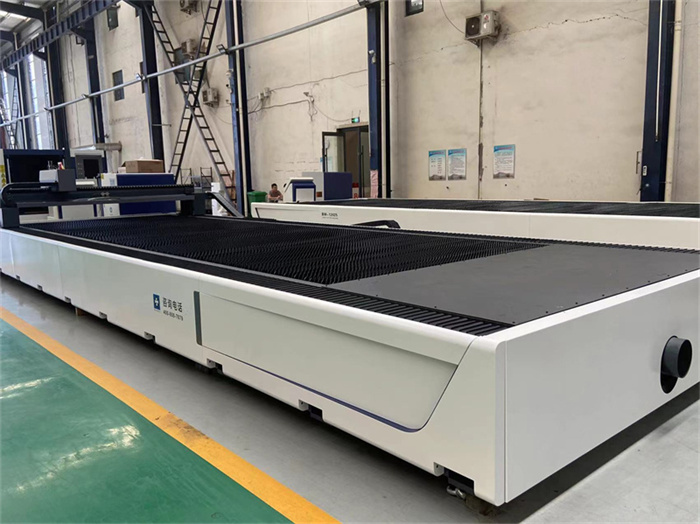

Sheet metal processing industry

With the rapid development of sheet metal processing technology, traditional sheet metal cutting equipment can no longer meet the requirements of current technology and cutting shape. Laser cutting has gradually replaced traditional equipment with the advantages of high flexibility and fast cutting speed. Fiber laser cutting machine Widespread application in sheet metal processing is an inevitable trend.

Sheet metal processing industry

Laser cutting can be described as a major change in sheet metal processing. Due to the high level of flexibility of laser cutting, fast cutting speed, high cutting efficiency, and short product work cycle, it immediately became the darling of the sheet metal processing industry. Laser cutting has no cutting Force, no deformation during processing; no tool wear, no matter what kind of parts it is, it can be cut by laser in one fine and rapid prototyping. In addition, the laser cutting seam is often narrow, and the cutting quality is good, the automation level is high, the labor intensity is low, and there is no pollution. When processing accessory cabinets and file cabinets, it is often the standardized production of thin plates. Using a laser cutting machine for cutting processing is more efficient and faster to complete the cutting processing requirements.