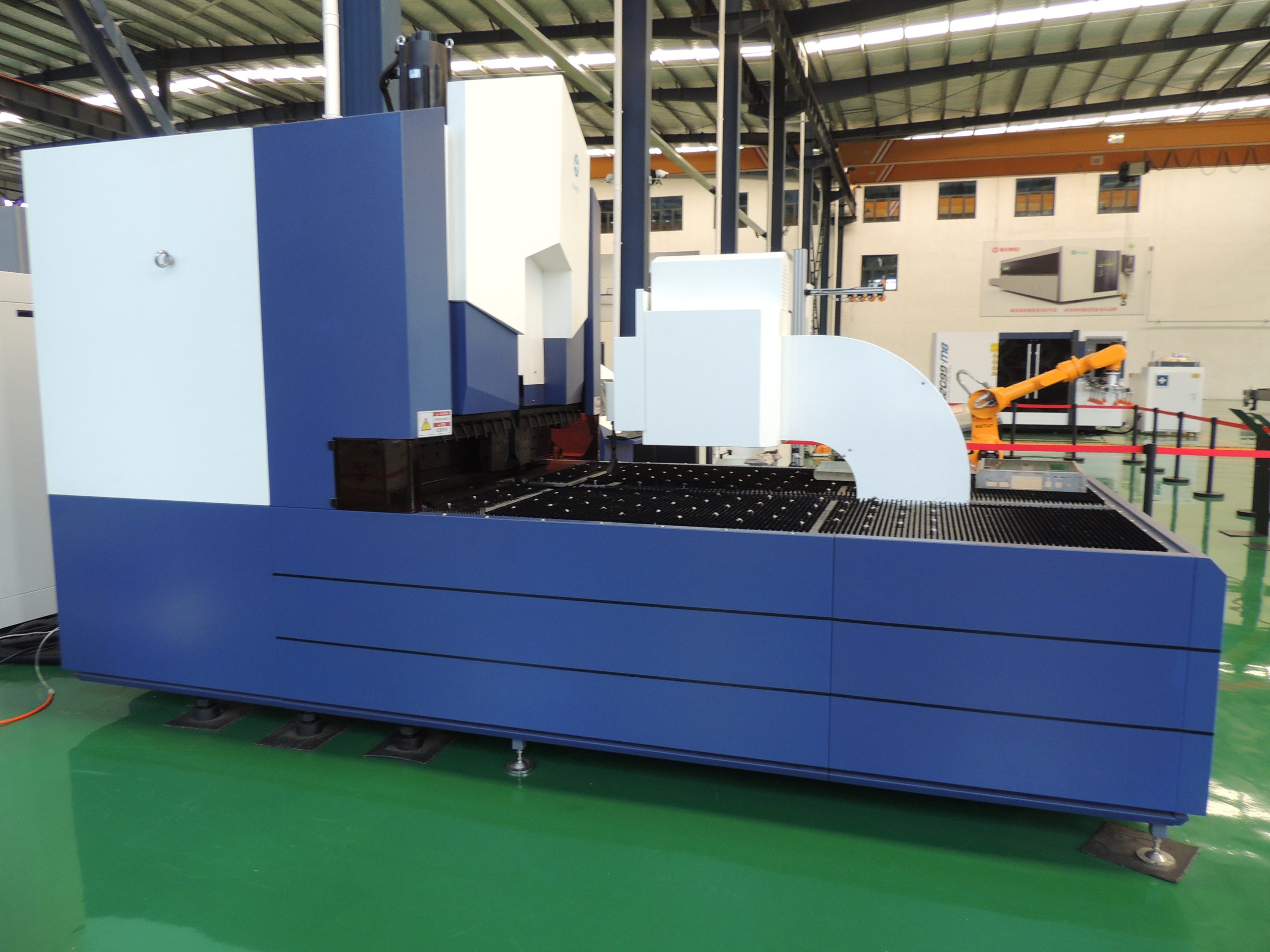

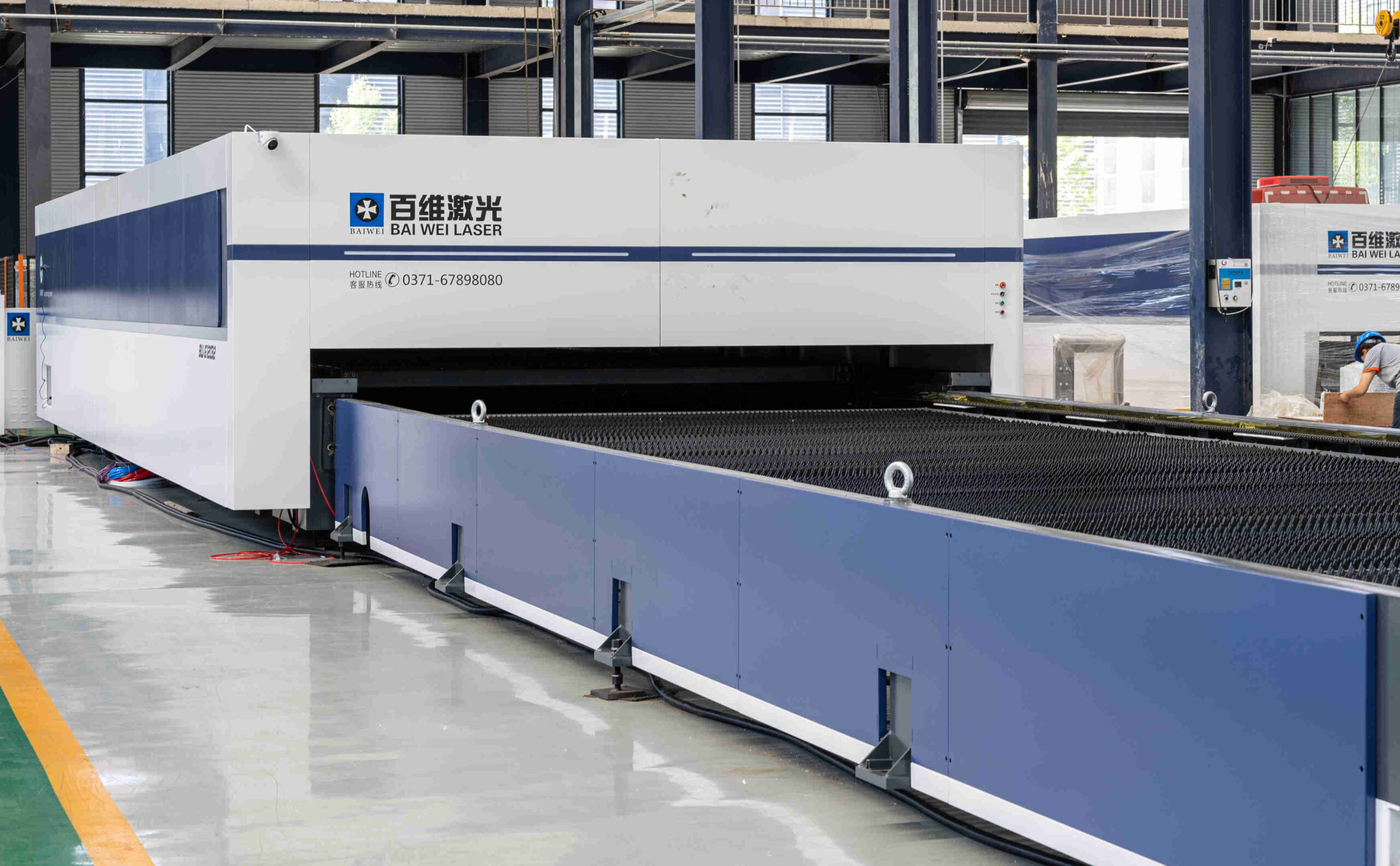

Automatic flexible bending center, Panel bender cnc machine

Maximum bending speed: 0.2 second/shot

Maximum bending width: 1400mm

Bending height:About 170mm(customizable)

The rated voltage:380V

Peak power:about 18KW

Average power:about 1.8KW

The noise:about 50 decibels

Dimensions:440cm*190cm*290cm

The total quality:about12tons

Maximum beding thicknessUTS 515N/mm2 201stainless steel 0.8mm

(standard) UTS 520N/mm2 304stainless steel 1.0mm

(Optional thickness) UTS 410N/mm2 304cold plate 1.2mm

UTS 265N/mm2 304Aluminum plate 1.6mm

Minimum material thickness:about0.35mm

Minimum inner dimensions:about140mm*190mm

Minimum inner size:about140mm

Minimum bending size:about1400mm*1400mm

Number of shaf:standard 13axis concurrent linkage

Conventional hinge cutter:(option)

Power hinge cutter:(option)

1. High degree of automation, easy operation and strong compatibility

√Industry 4.0 architecture, which can be upgraded smoothly;

√No molding required, complex shapes (folded up or down right angles, non-right angles)

√Free design and production at any time;

√Wide range of applicable materials, mainly stainless steel, cold-rolled plate, etc.;

√Compatible with various loading and unloading methods: manual loading and unloading, self-driven robotic arm loading and √unloading, and docking robotic arm loading and unloading are all optional.

2. Higher efficiency and lower cost

√Fast speed, only 0.2 seconds per knife;

√Rapid prototyping of workpieces with high consistency;

√Low power consumption, simple daily maintenance and low cost;

√High degree of automation, simple operation, low labor requirements;

√Friendly man-machine interface, easy to understand, flexible programming;

√For workpieces with non-standard sizes, different positioning references can be selected according to the shape of the workpiece, and the shearing error of the plate can be controlled on the first bending edge to ensure the dimensional accuracy after forming.