Application of laser cutting machine in manufacturing

Speaking of metal laser cutting machines, it has been around for a long time. It may have been there for thirty or forty years. Now it is getting better and better. There are more and more brands of metal laser cutting machines. It can be said that there are all over the country. It is still rising. So which brand of metal laser cutting machine is better?

Speaking of metal laser cutting machines, it has been around for a long time. It may have been there for thirty or forty years. Now it is getting better and better. There are more and more brands of metal laser cutting machines. It can be said that there are all over the country. It is still rising. So which brand of metal laser cutting machine is better?

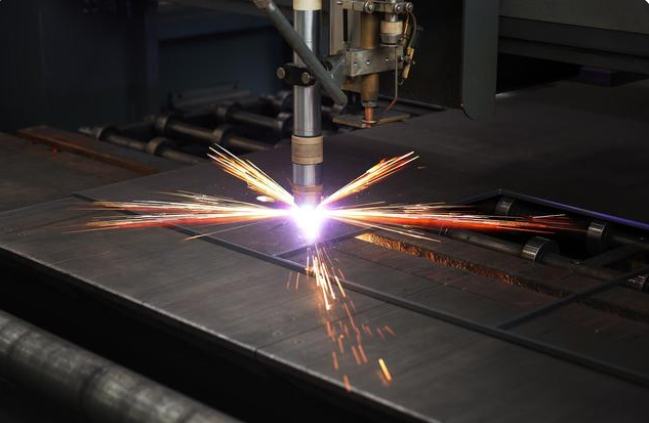

Laser cutting is currently very suitable in the field of medium and thin plates. The speed of the laser is fast, the heat-affected zone is small and no noise is generated during processing. The size of the laser beam, the output power and the traveling speed can be adjusted, so the laser can be applied in a wide range of fields.

Laser cutting is currently widely used in manufacturing, which has irreplaceable advantages and is superior to other processing technologies. At present, the common metal manufacturing materials on the market are mainly medium and thin plates. The advantages of laser cutting speed, high precision, and no deformation of the cost can make the manufacturing industry produce better and more efficiently.

During the cutting process of metal plates, if a saw blade or shearing machine is used to cut, the cost will usually be significantly deformed at the cutting end. If you want to use it in the next step, you need to perform a calibration process, and there will be obvious residues on the cutting section. Clean it up. very time consuming. If the flame plasma cutting process is used, the heat affected zone is large, and the cutting section will basically have obvious overmelting phenomenon, forming a pitted gap. In laser processing, the heat-affected zone is small, the processing accuracy is high, the cutting section is flat and smooth without burrs and slag, and the material is basically free of deformation, and the processing speed is also faster than the above two cutting processes.

In the field of metal cutting, laser cutting is undoubtedly a better processing technology. A laser cutting machine can not only cut off but also punch holes and engrave patterns, replacing the traditional multi-channel process, shortening the original complicated multi-channel processing into one process, making the overall Productivity is faster. This is the advantage of the current laser cutting processing technology, I hope to be helpful to you.

Baiwei Laser Technology Development Co., Ltd., established in 2004, is committed to providing high-quality laser application equipment solutions for global users. After 18 years of development, it has developed into a leading enterprise in the manufacture of laser application intelligent equipment in northern China, with Henan , Guangzhou two production bases, more than 900 employees, export sales to the United States for several consecutive years, the country’s first, is also a domestic leader in high-end quality laser application intelligent equipment. Baiwei Laser is synonymous with high quality laser equipment.