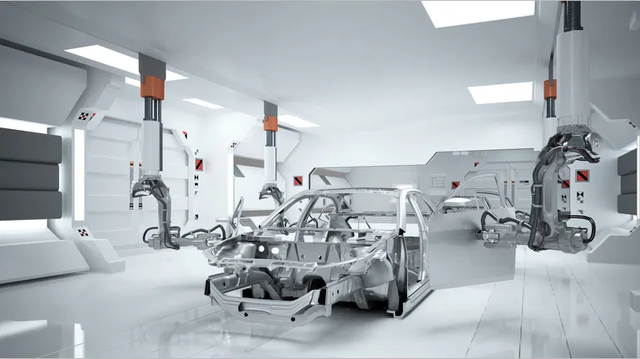

Application advantages of laser cutting machine in automobile manufacturing industry

The automobile manufacturing industry is an industry with a very high concentration of new technologies. It meets the needs of export and domestic continuous upgrading. Small batches and multi-variety vehicle production are the norm. The original GM body parts processing technology cannot fully meet the current product quality and quality. The needs of production, now the car not only requires performance and practicality, but also requires economical beauty, and the speed of replacement is increasing day by day.

With the development of laser application technology, laser cutting technology is widely used in various aspects such as auto parts, auto bodies, auto door frames, auto trunks, auto roof covers, etc., basically covering all application fields in the automotive manufacturing industry. The laser cutting machine has the characteristics of processing high-precision, porous and complex-shaped accessories. Compared with traditional cutting methods, it has low efficiency and low precision. It is very suitable for the modern automobile manufacturing industry. It plays an irreplaceable role in other CNC cutting equipment.

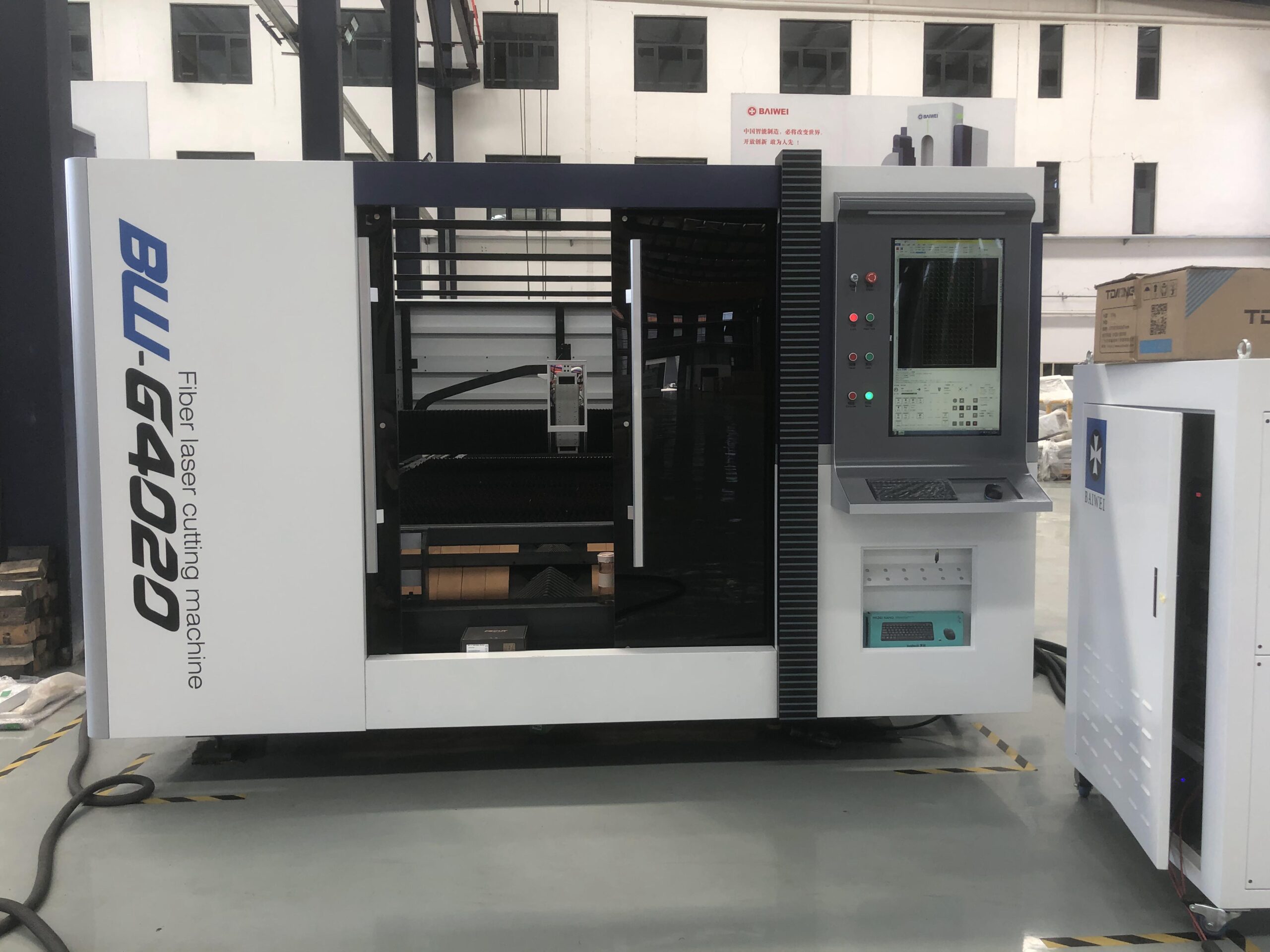

The main advantages of Baiwei laser cutting machine widely used in the automobile manufacturing industry are as follows:

Advantage 1. Production material suitable for a variety of accessories

Thousands of accessories are included in automobile manufacturing, including mild steel, high strength steel, high strength low alloy, advanced high strength steel, ultra high strength steel, aluminum 5000/6000, carbon fiber reinforced plastic aluminum, carbon fiber composite materials, Magnesium, titanium, various types of plastics. Laser cutting equipment can process almost the production material for cars and all their accessories.

Advantage 2 to improve production efficiency

The cutting speed of laser cutting machine can reach 100 meters per minute. Compared with traditional cutting, laser cutting has higher positioning accuracy and fast cutting speed, which can meet the processing requirements of high-precision accessories, which can directly shorten the processing and manufacturing cycle and improve production. efficiency, shorten the delivery time.

Advantage 3: High utilization rate of materials

The laser cutting equipment has a large processing format and can be used to cut the entire sheet. When cutting accessories, you can cut different accessories of the same thickness and material, making full use of the leftovers of the raw material. The complex pattern can be cut accurately, and the modification is convenient, the error is small, the cutting surface has no burr, and the laser cutting machine is also more flexible when cutting medium and small batches, large areas and complex contour shapes.

Advantages Four hot spots have little impact

During the cutting process of Baiwei laser cutting machine, the edge of the material to be cut will generate a hot zone due to heat.

But compared to other processing methods, Xunlei laser cutting machine has less energy concentration and less heat input. Compared with fine plasma cutting and flame cutting, it is of great significance in the processing of ferritic stainless steel that is prone to grain growth by heating and high-strength steel that is prone to hardening, and is conducive to improving the quality of welds.

Advantage five save production cost

The laser cutting machine has stable performance, is sturdy and durable, and is not easy to be damaged. Laser cutting does not require molds, which can save mold investment, and the cut products have no extrusion deformation. The processed products are of good quality and reduce production costs.