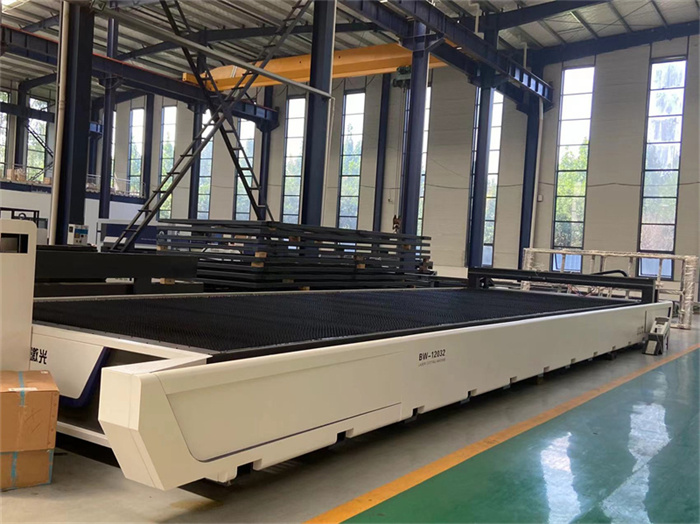

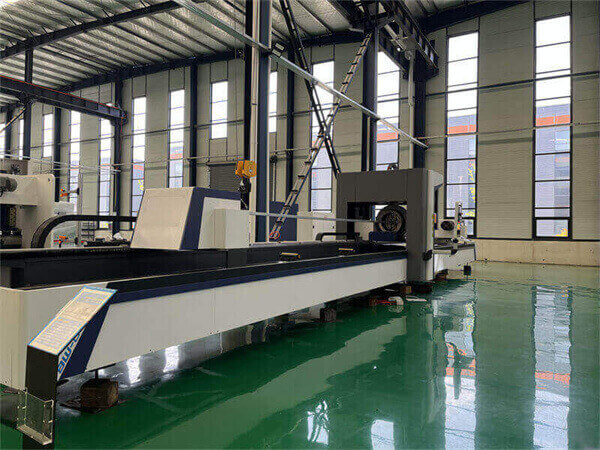

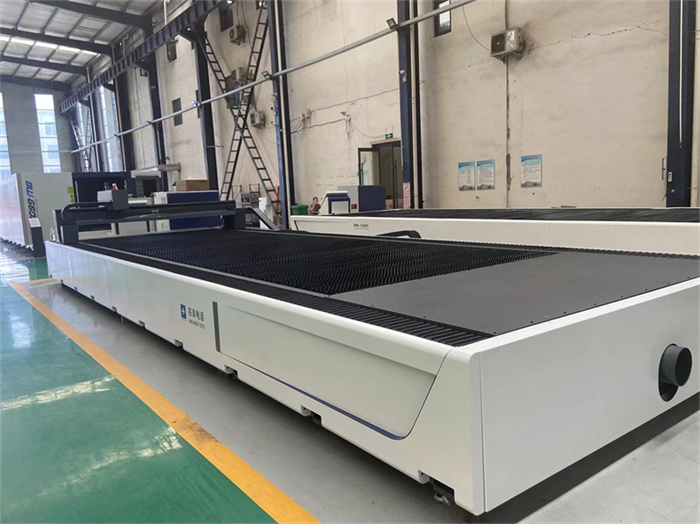

Adequate steel plate closed type fiber laser cutting machine

Model: BW-G6025

Cutting range: 6000x2500mm (Optional)

Laser power: 1kw/2kw/3kw/4kw/6kw/8kw/10kw/12kw/15kw/20kw/30kw (Optional)

Max moving speed: 120m/min

Max cutting speed: 35-80m/min

Positioning accuracy: 0.03mm

Repositioning accuracy: 0.02mm

Min line width: 0.1mm

Compare from maintenance cost

In terms of machine maintenance, fiber laser cutting is more environmentally friendly and convenient. The carbon dioxide gas laser system needs regular maintenance; the reflector needs maintenance and calibration, and the resonant cavity needs regular maintenance. On the other hand, the fiber laser cutting solution requires almost no maintenance. The carbon dioxide laser cutting system requires carbon dioxide as the laser gas. Due to the purity of carbon dioxide gas, the resonant cavity will be contaminated and needs to be cleaned regularly. For a multi-kilowatt carbon dioxide system, this item requires at least US$20,000 per year. In addition, many carbon dioxide cutting requires high-speed axial turbines to deliver laser gas, and turbines require maintenance and overhaul.