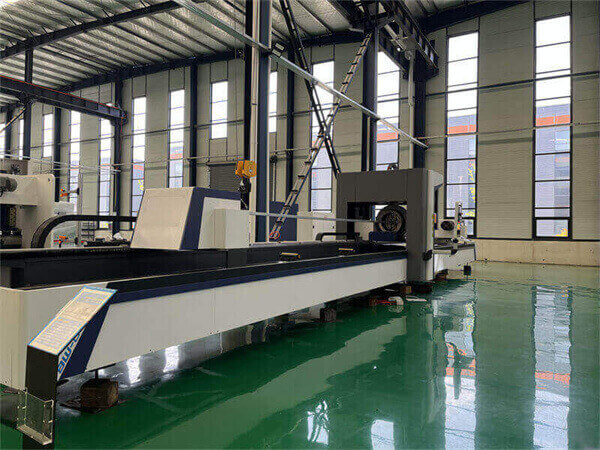

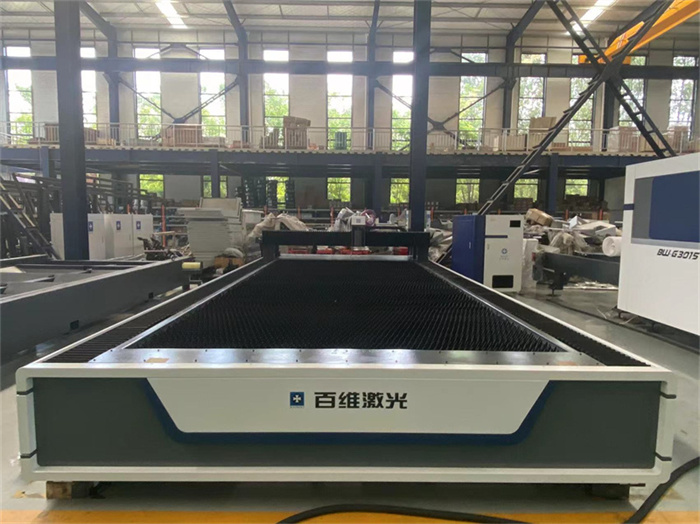

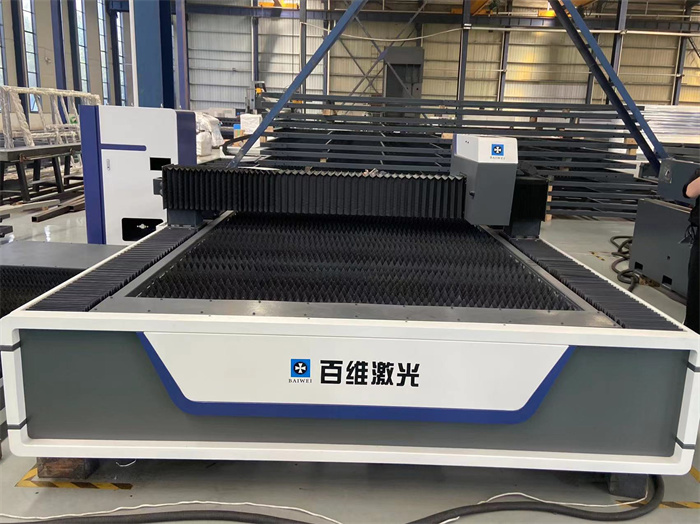

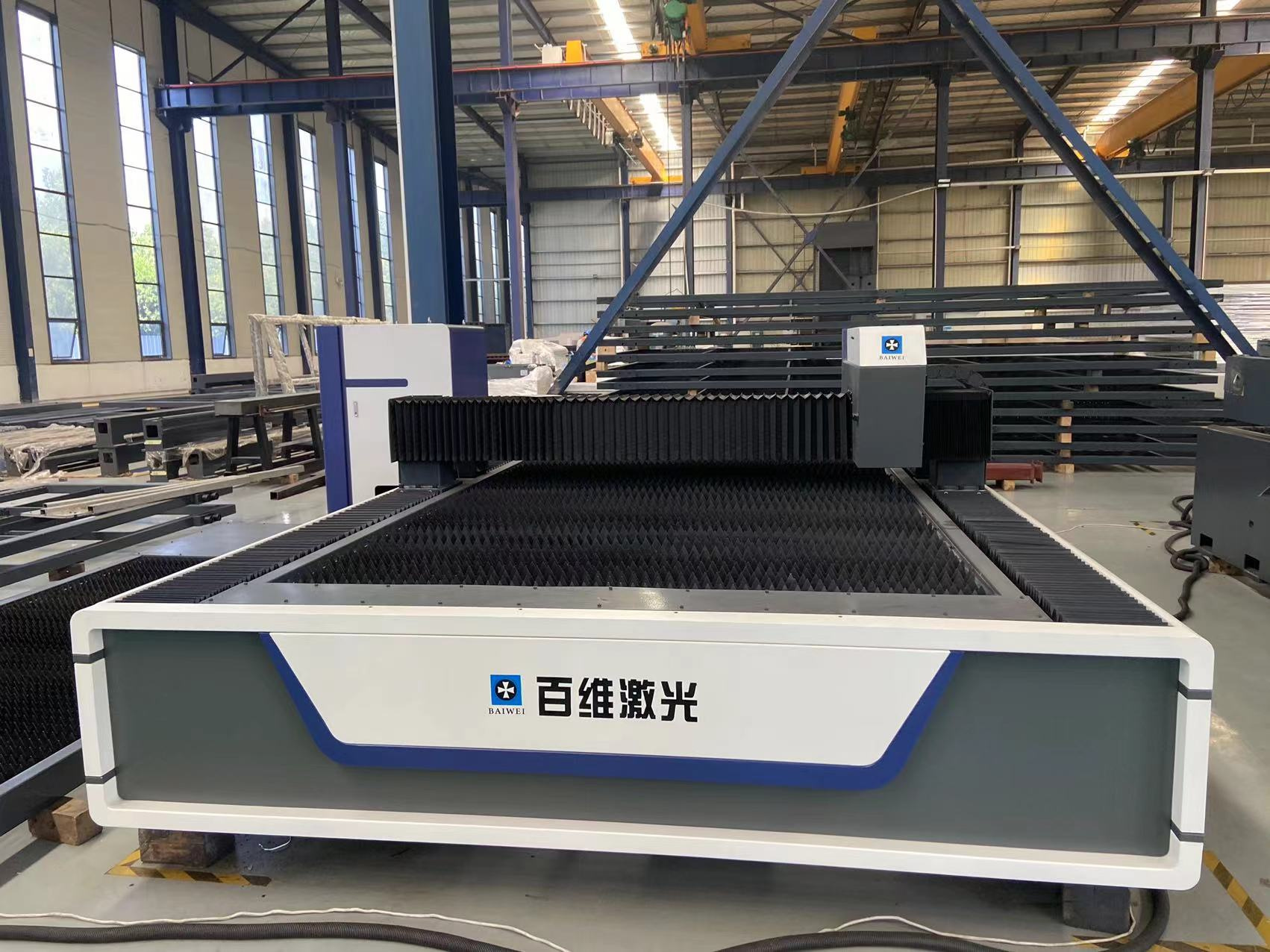

1530 3015 CNC Metal Stainless Steel Carbon Plate Fiber Laser Cutter Cutting Machines

Baiwei The laser can check the running status of the customer’s laser cutter through our remote maintenance system. Our technicians can perform troubleshooting via remote access instead of on-site diagnosis and maintenance, saving you much time.

Advantages of Fiber Laser Cutting Machine

1) Excellent beam quality: Smaller focus diameter and high work efficiency, high quality.

2) High cutting speed: Cutting speed is more than 20m/min

3) Stable running: Adopting the top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4) High efficiency for photoelectric conversion: Compared with CO2 laser cutting machine, fiber laser cutting machine has three times the photoelectric conversion efficiency

5) Low cost & Low maintenance: Save energy and protect the environment. The photoelectric conversion rate is up to 25-30%. Low electric power consumption is only about 20%-30% of traditional CO2 laser cutting machines. Fiber line transmission not need to reflect lens, which save maintenance cost;

6) Easy operations: fiber line transmission, no adjustment of the optical path;

7) Super flexible optical effects: Compact design, easy to flexible manufacturing requirements.